A side wall window structure module of a train and the train

A technology of structural modules and windows, applied in window devices, windows/doors, railway car bodies, etc., can solve the problems of easy distortion, weak buckling resistance, weak compression and impact resistance of side wall window structural modules, etc. Achieve the effect of not easy to twist and deform, not easy to twist and deform, and strong buckling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

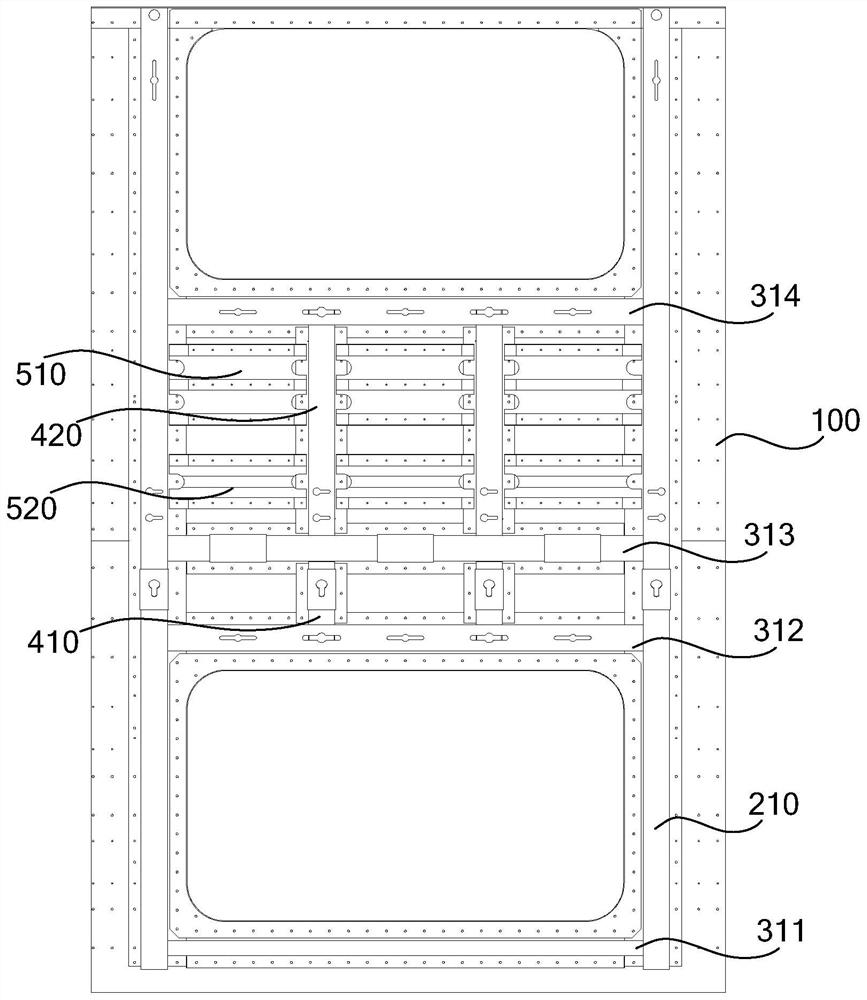

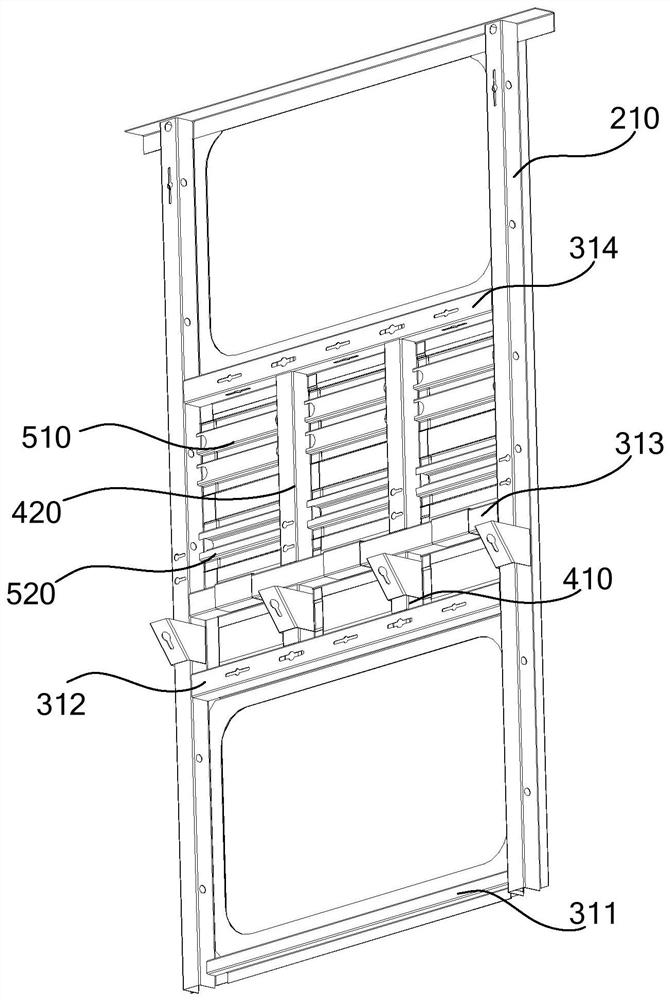

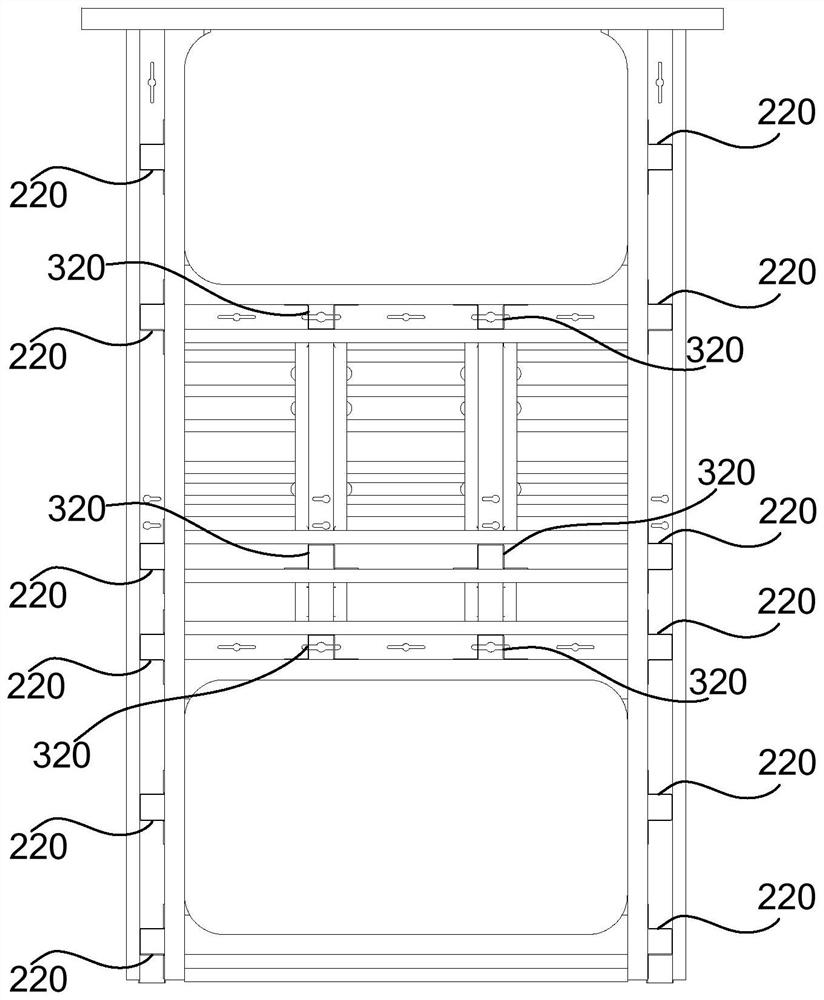

[0045] figure 1 It is a schematic diagram of a side wall window structure module of a train according to an embodiment of the present application; figure 2 for figure 1 The perspective schematic diagram of the side wall window structure module with the window wall plate removed as shown; image 3 for figure 2 A schematic diagram of the side wall window structure module facing the wall plate with the window wall plate removed. Such as figure 1 , figure 2 with image 3 As shown, a side wall window structure module of a train in the embodiment of the present application includes:

[0046] window wall panel 100;

[0047] Z-shaped support, the two flanges of the Z-shaped support are fixed on the inner side of the window wall panel;

[0048] A several-shaped reinforcement, the two flanges of the several-shaped reinforcement are fixed to one side of the several-shaped support, and the arched high side of the several-shaped reinforcement is connected to the two-shaped suppo...

Embodiment 2

[0096] The train of the embodiment of the present application includes the side wall window structure module described in the first embodiment.

[0097] In implementation, the train also includes:

[0098] A plurality of zigzag connecting beams, the flanges of each zigzag connecting beam span two adjacent window wall panels, and are fixed with the window wall panels to connect the two side wall window structures The modules are fixedly connected.

[0099] In this way, the two adjacent side wall window structure modules are fixedly connected by a zigzag connecting beam.

[0100] In implementation, the train also includes:

[0101] A plurality of profiled connecting beams, the longitudinal direction of each of the profiled connecting beams is double-shaped; the flange of each of the profiled connecting beams spans two adjacent window wall panels, and is connected to the The window wall panels are fixed to connect the two side wall window structure modules fixedly.

[0102] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com