Corrugated plate type I-shaped structural beam and its construction method

A corrugated plate type and corrugated plate technology, which is applied to the corrugated plate type I-shaped structural beam and the construction field, can solve the problems of limited buckling resistance, large difficulty and workload, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

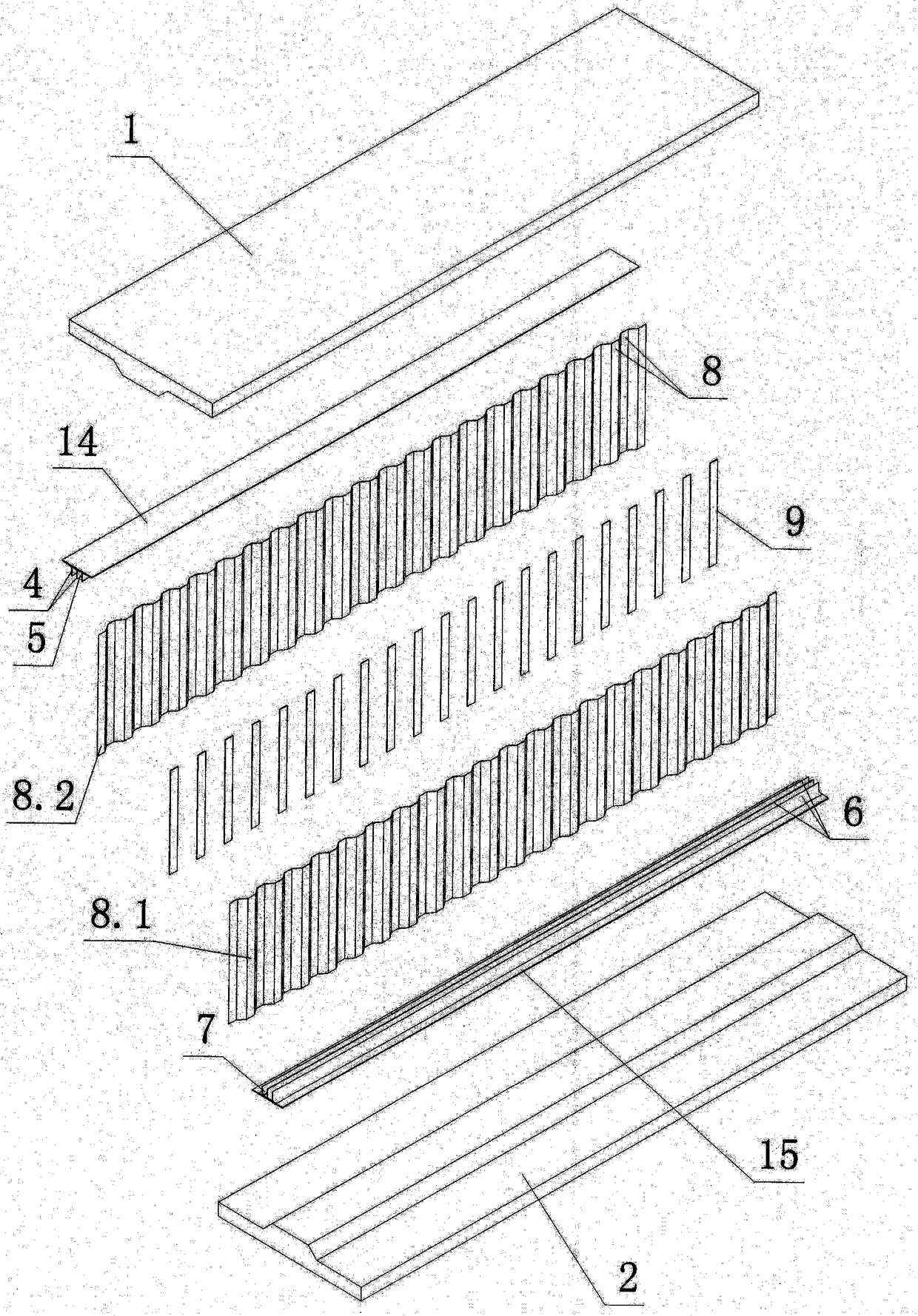

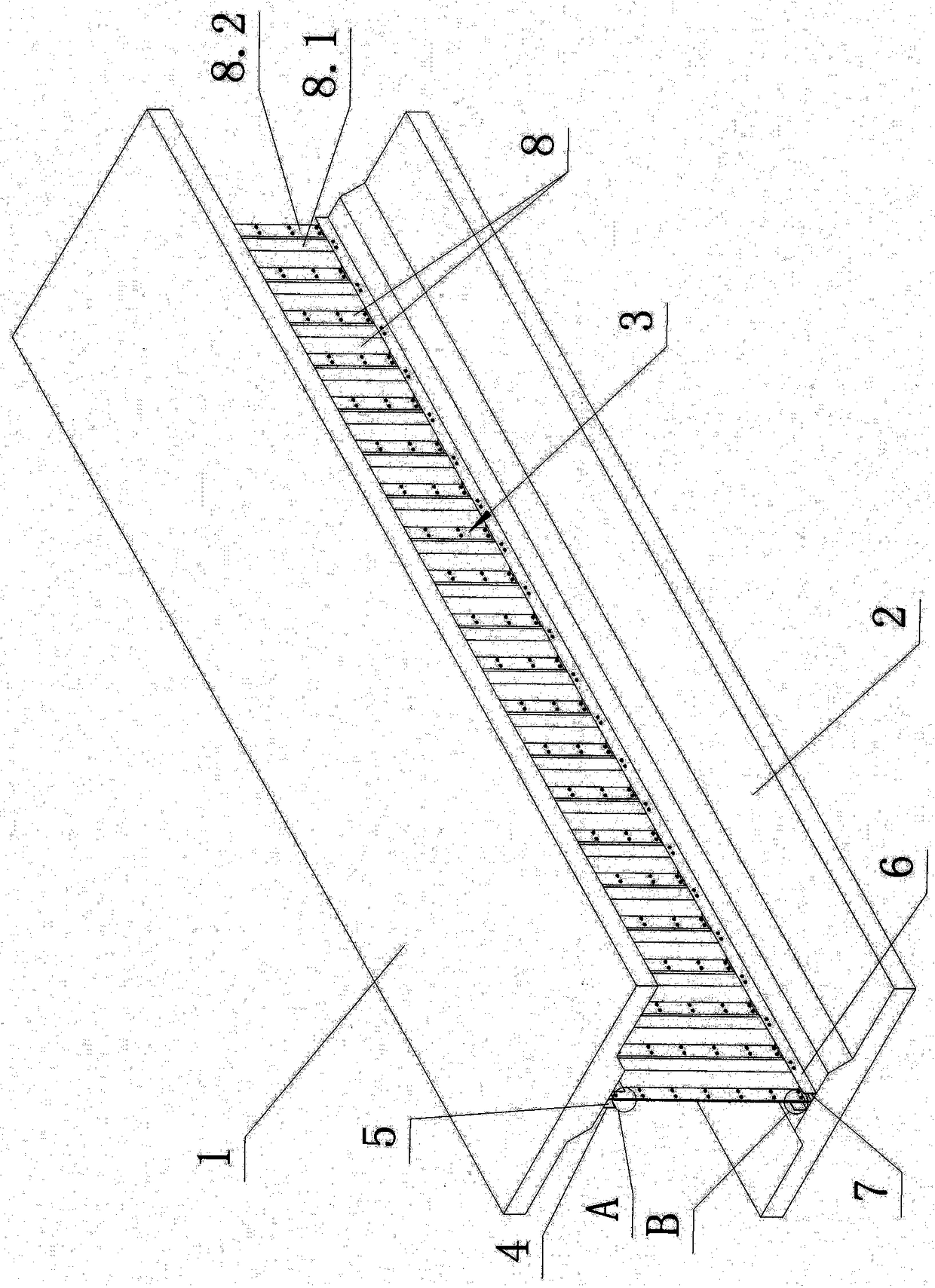

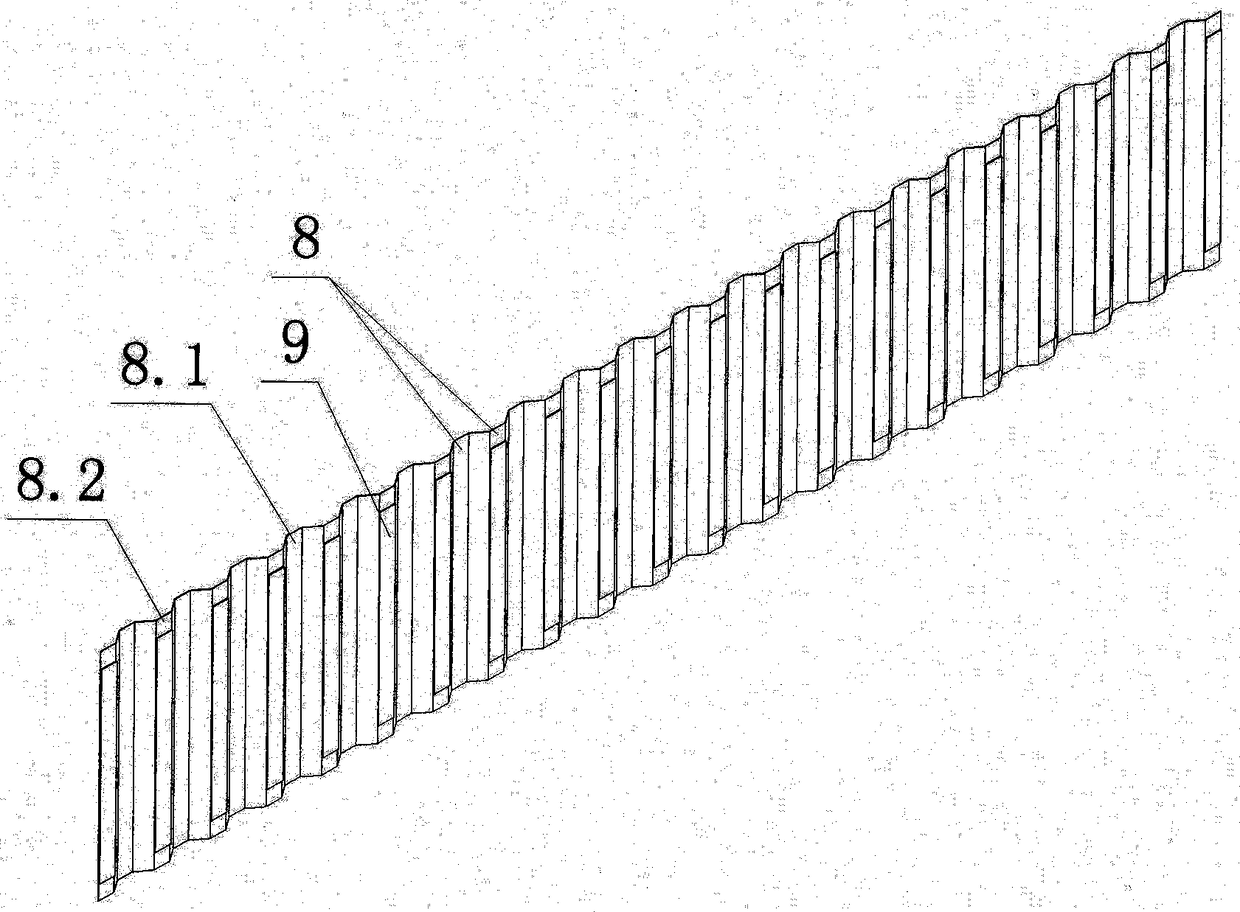

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the corrugated plate type I-shaped structural beam of the present invention includes an upper flange plate 1 , a lower flange plate 2 and a web 3 .

[0031] The upper flange plate 1 is provided with an upper mounting seat, and the upper mounting seat includes three parallel upper guide plates 4 , and two upper guide grooves 5 are formed between the three upper guide plates 4 . The upper flange plate 1 of this embodiment is a reinforced concrete structure, of course, the upper flange plate 1 of a pure steel structure can also be used. The upper mount also includes a steel top plate 14 vertically welded with three upper guide plates 4 , the steel top plate 14 is parallel to the upper flange plate 1 and the steel top plate 14 is pre-embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com