Door module and fastener for door module

一种车门、用具的技术,应用在车门模块用固定用具领域,能够解决难以确保作业空间、对位的作业烦杂等问题,达到容易组装、实现部件个数、推进自动化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

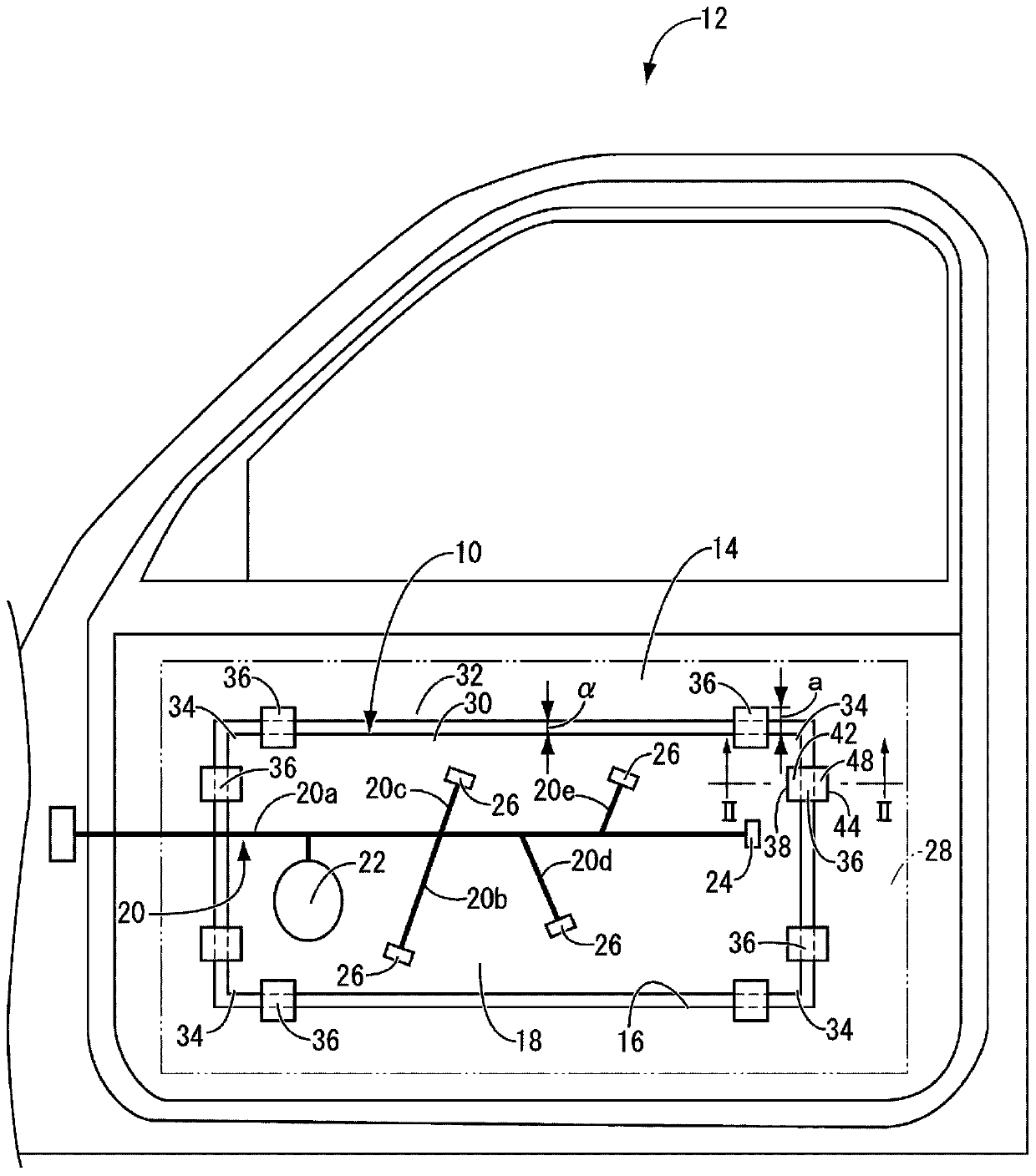

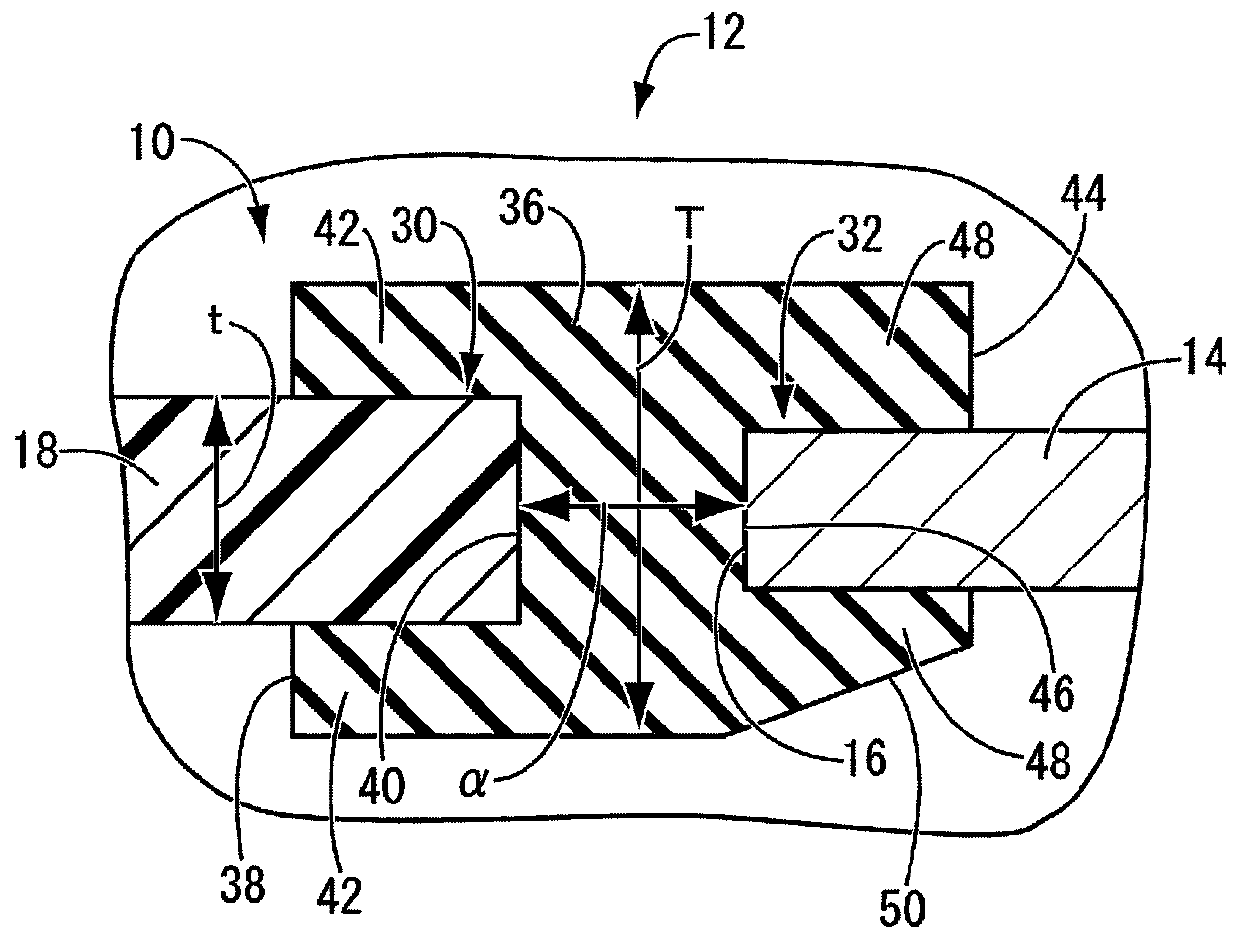

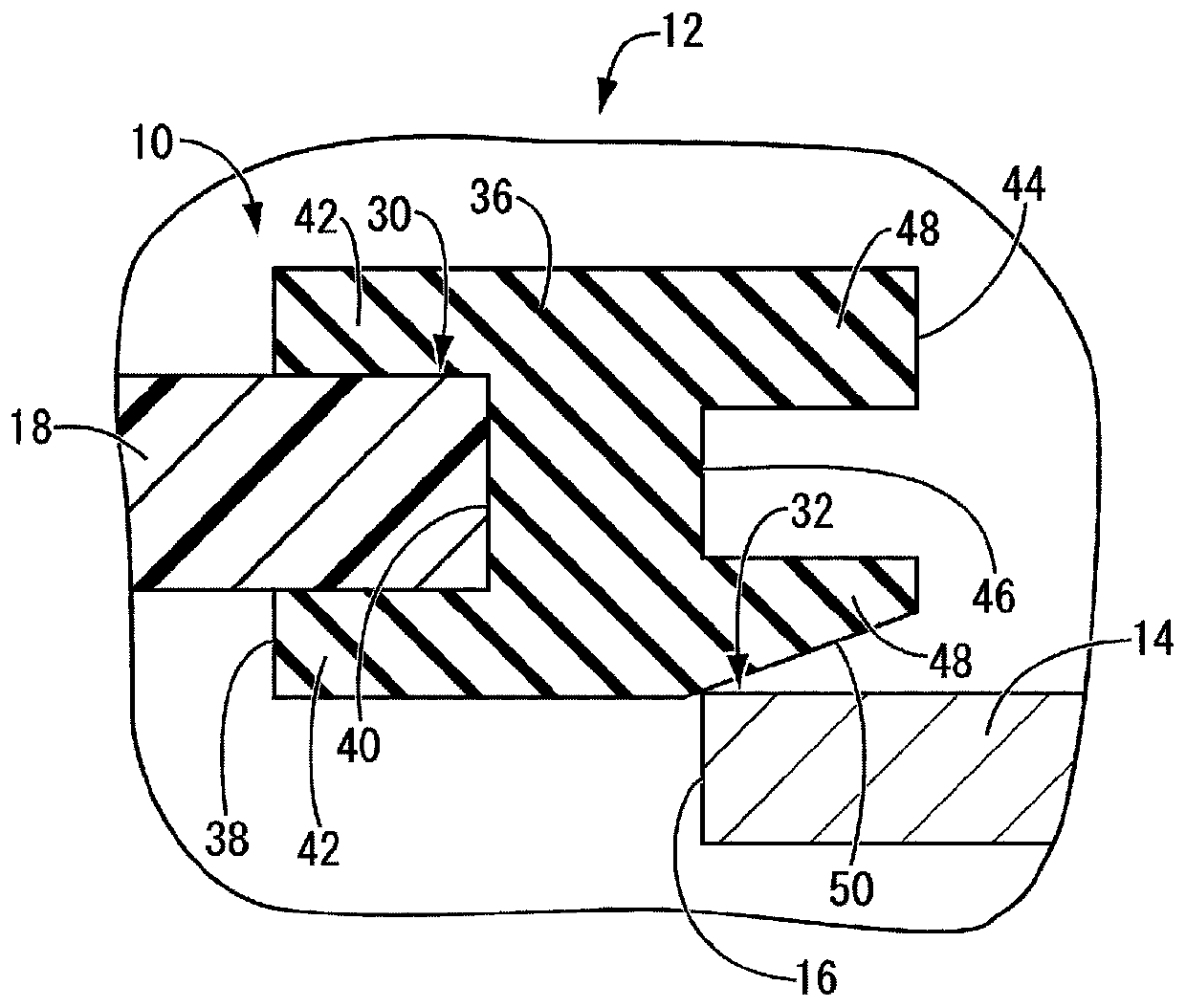

[0037] Figure 1~3 A door portion 12 including a door module 10 according to the first embodiment of the present invention is shown. Such as figure 1 As shown, on the interior side of the vehicle door 12 ( figure 1 The door inner panel 14 on the front side) is provided with an inspection hole 16 having a substantially rectangular cross-sectional shape that opens toward the interior side. The above-mentioned inspection hole 16 is provided for inserting fingers, tools, parts, etc. into the interior of the door portion 12 during inspection. occlusion. In the description below, above refers to figure 1 In the above, below refers to figure 1 below, and the front refers to the figure 1 To the left of the center, the rear refers to the figure 1 The right side of the center, and then, the front side refers to the figure 1 The upper side in the direction perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com