Manufacturing process of antibacterial paper diaper for children

A production process and a technology for diapers, which are applied in the field of daily necessities, can solve the problems that diapers are difficult to effectively disinfect and antibacterial.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

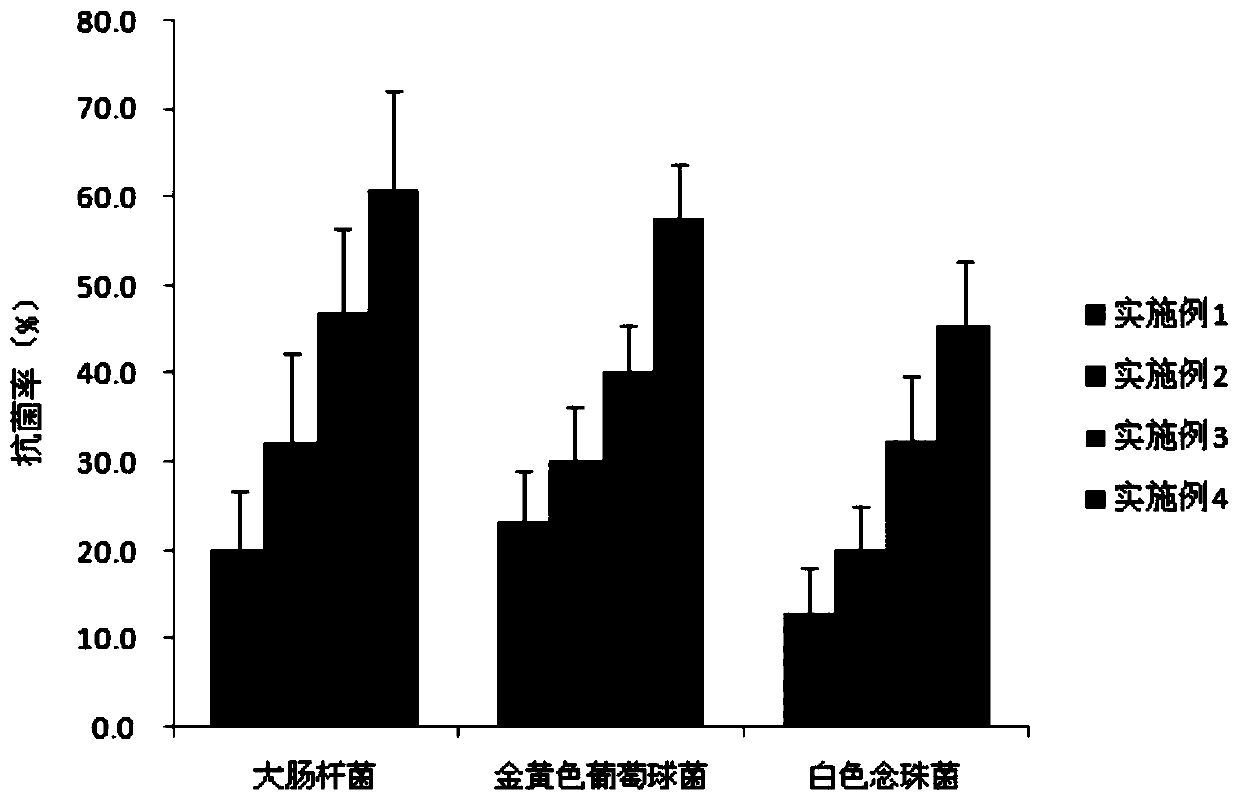

Embodiment 1

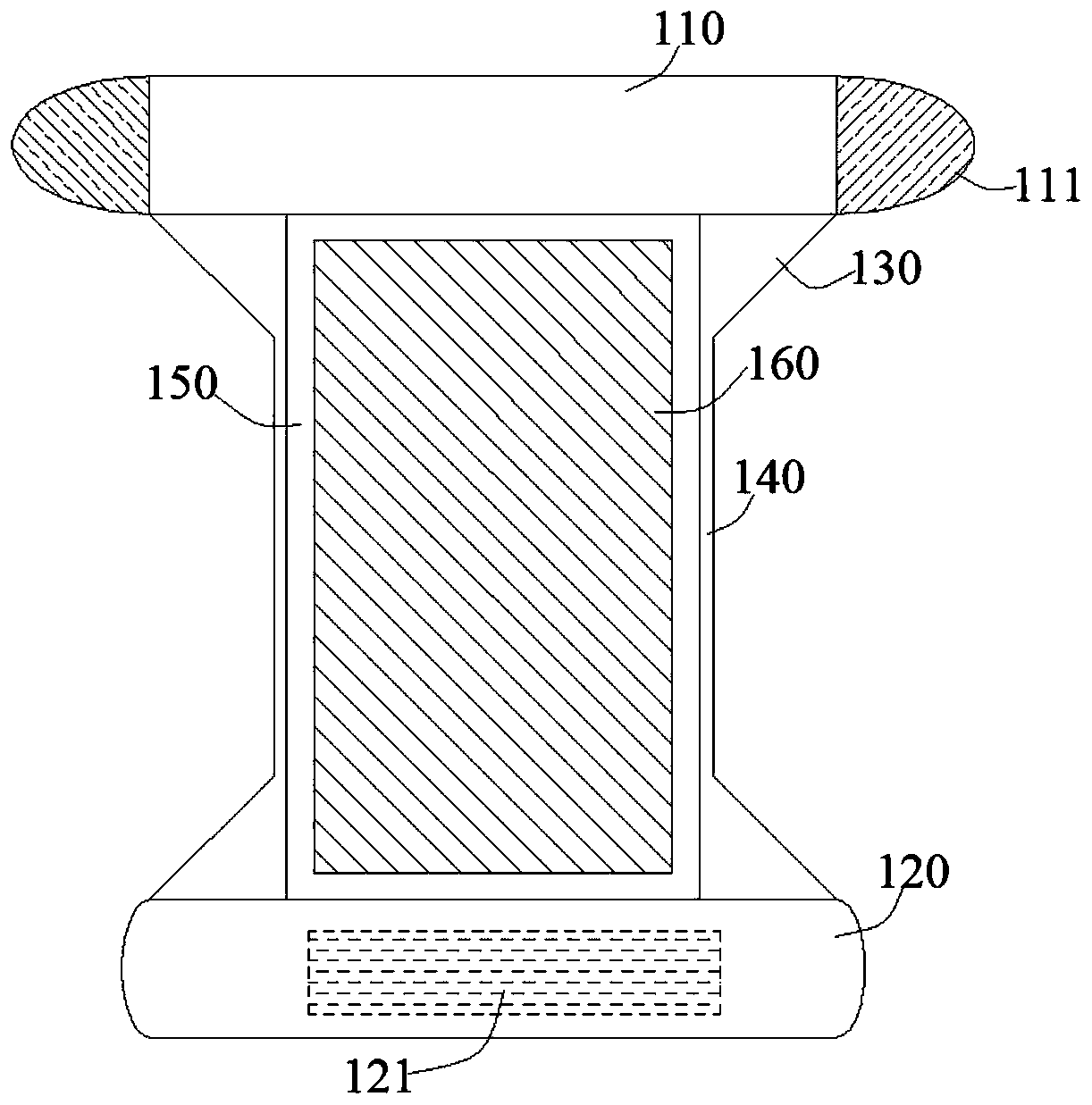

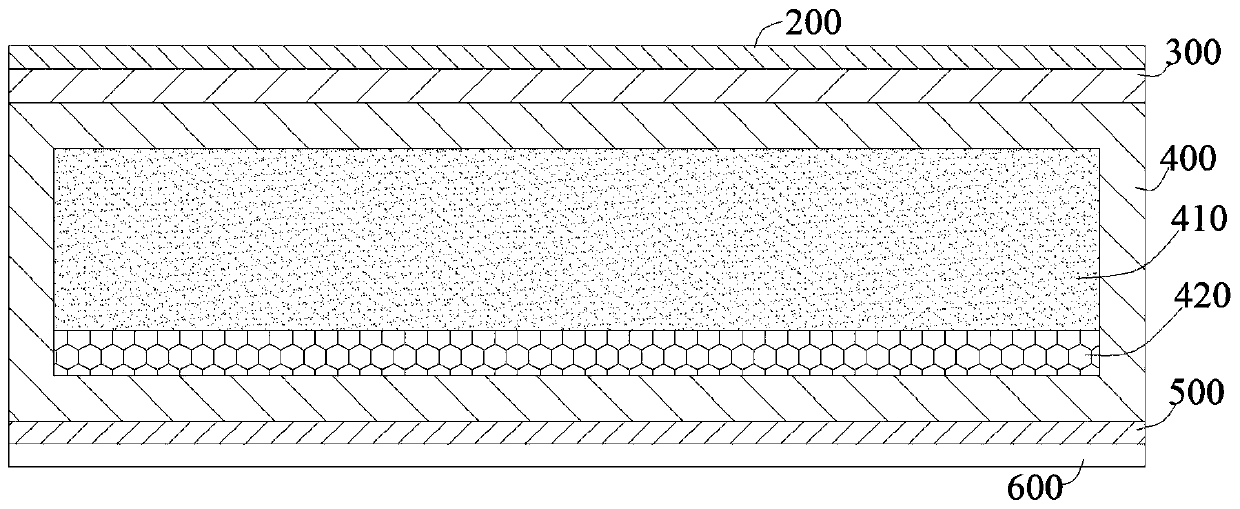

[0028] Refer to attached figure 1 - attached image 3 , the manufacturing process of a kind of antibacterial children's diaper of the present embodiment, the non-woven fabric that contains fullerene and derivative suspension is sewed on the position that diaper contacts with skin. The preparation method of the non-woven fabric containing fullerene and derivative suspension is to soak or spray the non-woven fabric with a mass fraction of 0.1% fullerene and derivative suspension and then dry it. The fullerene and its derivatives are C 60 Fullerene derivatives (fullerenols, n=28).

[0029] The diapers of this embodiment are sequentially stitched with a first non-woven fabric layer, a second non-woven fabric layer, a fluffy fiber web layer, a waterproof sealing layer and a third non-woven fabric layer, and the fluffy fiber web layer is filled with a layer of water-absorbing particles and In the antibacterial particle layer, the first non-woven fabric layer is a non-woven fabric...

Embodiment 2

[0034] Refer to attached figure 1 - attached figure 2 , the manufacturing process of a kind of antibacterial children's diaper of the present embodiment, the non-woven fabric that contains fullerene and derivative suspension is sewed on the position that diaper contacts with skin. The preparation method of the non-woven fabric containing fullerene and derivative suspension is to soak or spray the non-woven fabric with a mass fraction of 1% fullerene and derivative suspension and then dry it. The fullerene and its derivatives are C 60 Fullerene derivatives (fullerenols, n=28).

[0035] The diapers of this embodiment are sequentially stitched with a first non-woven fabric layer, a second non-woven fabric layer, a fluffy fiber web layer, a waterproof sealing layer and a third non-woven fabric layer, and the fluffy fiber web layer is filled with a layer of water-absorbing particles and In the antibacterial particle layer, the first non-woven fabric layer is a non-woven fabric ...

Embodiment 3

[0040] Refer to attached figure 1 - attached figure 2 , the manufacturing process of a kind of antibacterial children's diaper of the present embodiment, the non-woven fabric that contains fullerene and derivative suspension is sewed on the position that diaper contacts with skin. The preparation method of the non-woven fabric containing fullerene and derivative suspension is to soak or spray the non-woven fabric with a mass fraction of 5% fullerene and derivative suspension and then dry it. The fullerene and its derivatives are C 60 Fullerene derivatives (fullerenols, n=28).

[0041] The diapers of this embodiment are sequentially stitched with a first non-woven fabric layer, a second non-woven fabric layer, a fluffy fiber web layer, a waterproof sealing layer and a third non-woven fabric layer, and the fluffy fiber web layer is filled with a layer of water-absorbing particles and In the antibacterial particle layer, the first non-woven fabric layer is a non-woven fabric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap