Pipe fitting management device based on building construction

A technology for managing devices and building construction, applied in tool storage devices, manufacturing tools, etc., and can solve problems such as increased access and use, pipe fittings slipping, and pipe fittings clamped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

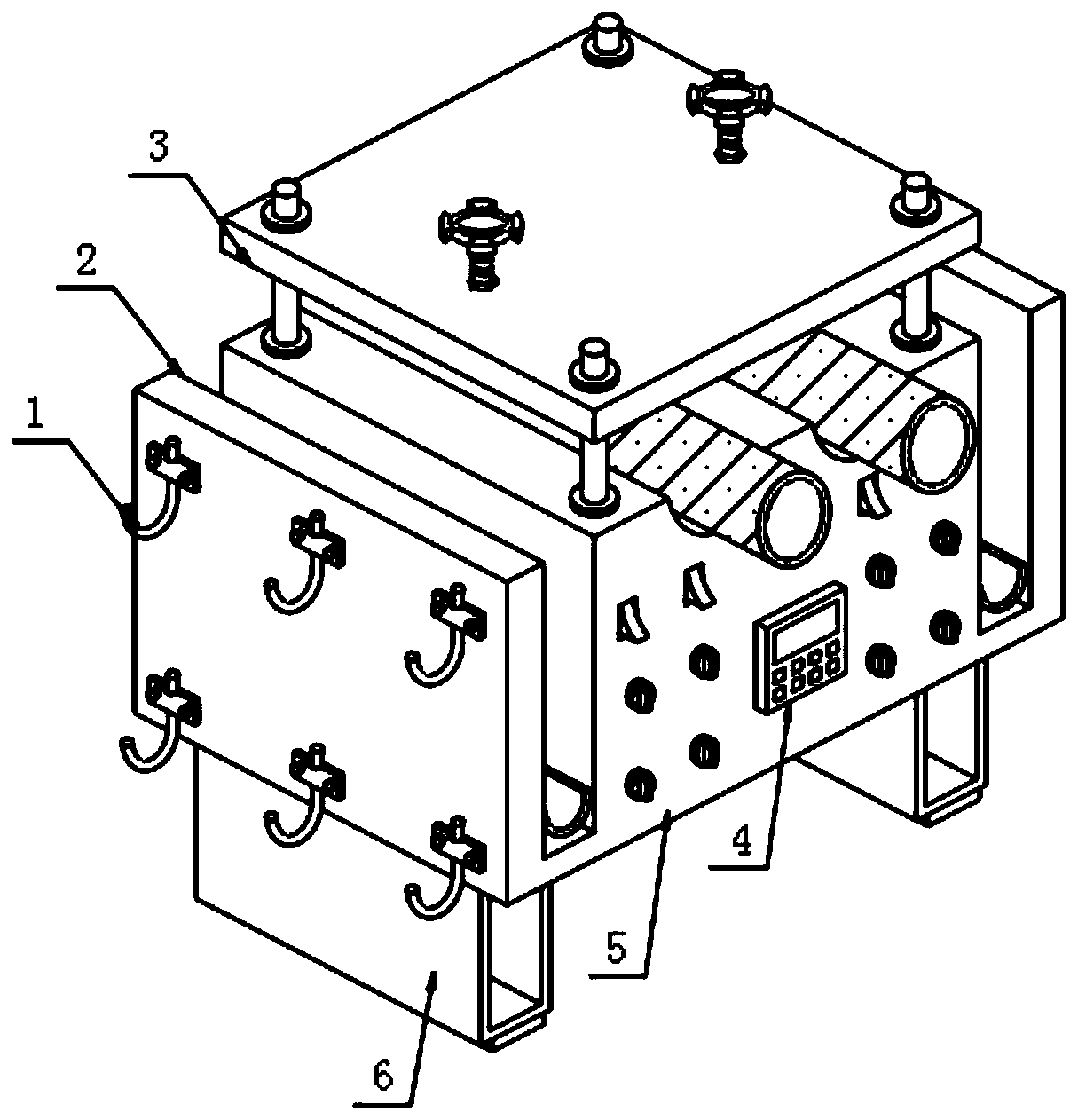

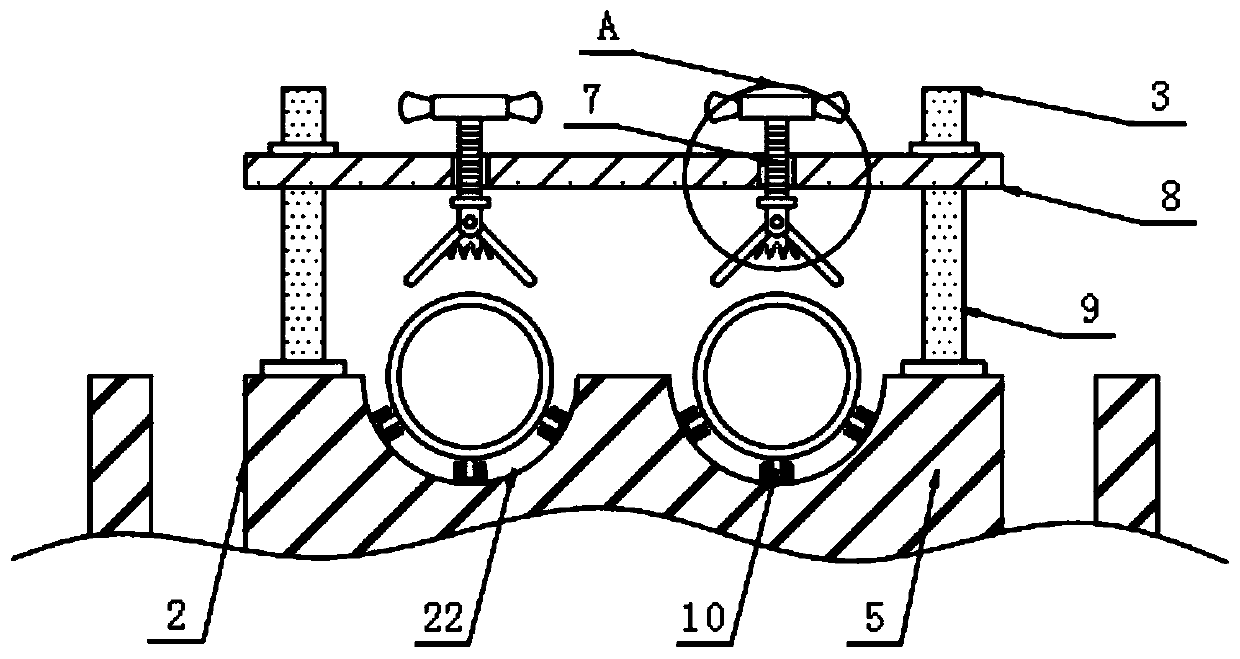

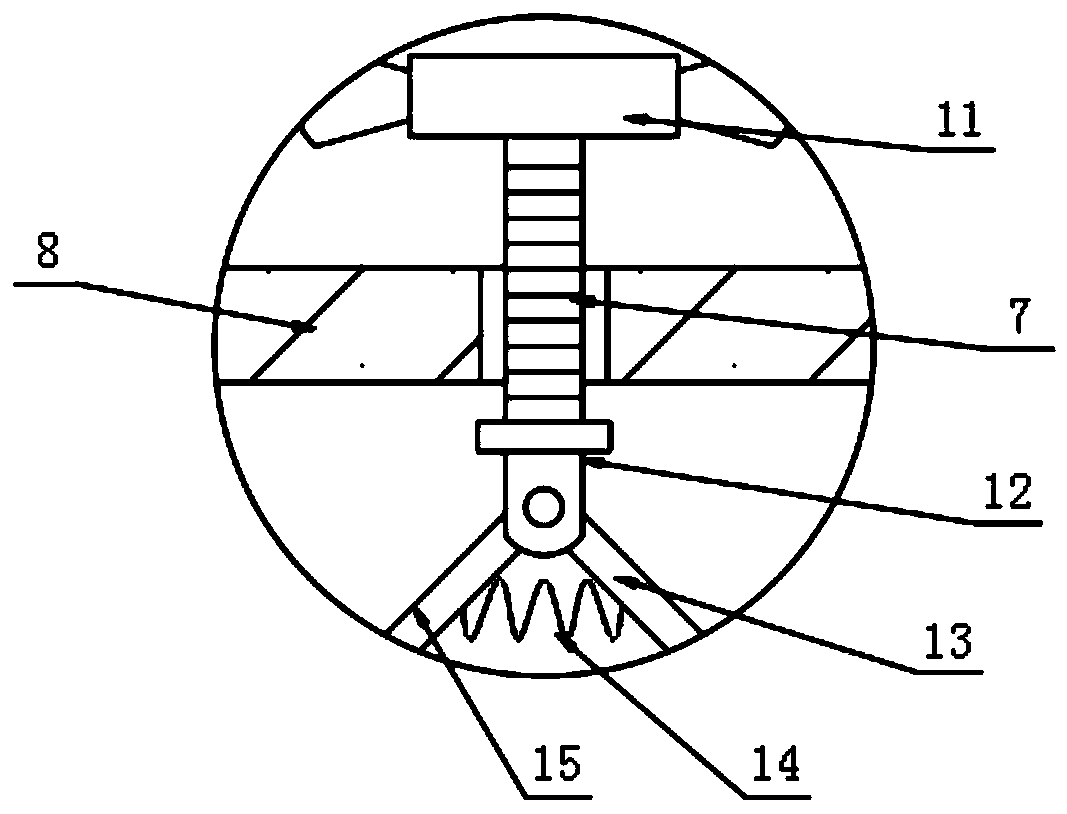

[0021] see Figure 1~4 , in an embodiment of the present invention, a pipe management device based on building construction, including a mounting base 5, a placement groove 2 is opened at the edge of the upper surface of the mounting base 5, and a control switch 4 is fixedly connected to the front surface of the mounting base 5 , the rear surface of the mounting seat 5 is fixedly connected with a storage battery, the inner wall of the placement groove 2 is provided with a limit chute 16 communicating with itself, and the bottom of the mounting seat 5 is also connected with a lifting assembly 6 along its own vertical direction, and the lifting assembly 6 Including a limit slide bar 17, a support pad 18, an electric push rod 19, a fixed seat 20 and an anti-skid support block 21, the fixed seat 20 is affixed to the bottom of the mounting seat 5, and the interior of the fixed seat 20 is affixed with an electric push rod 19. The bottom of the fixed seat 20 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com