Ink box recycling method and recycled ink box

A technology for ink cartridge recovery and ink recovery, which is applied in printing and other fields, and can solve problems such as ink absorption and control ability weakening, lower ink cartridge performance, ink leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

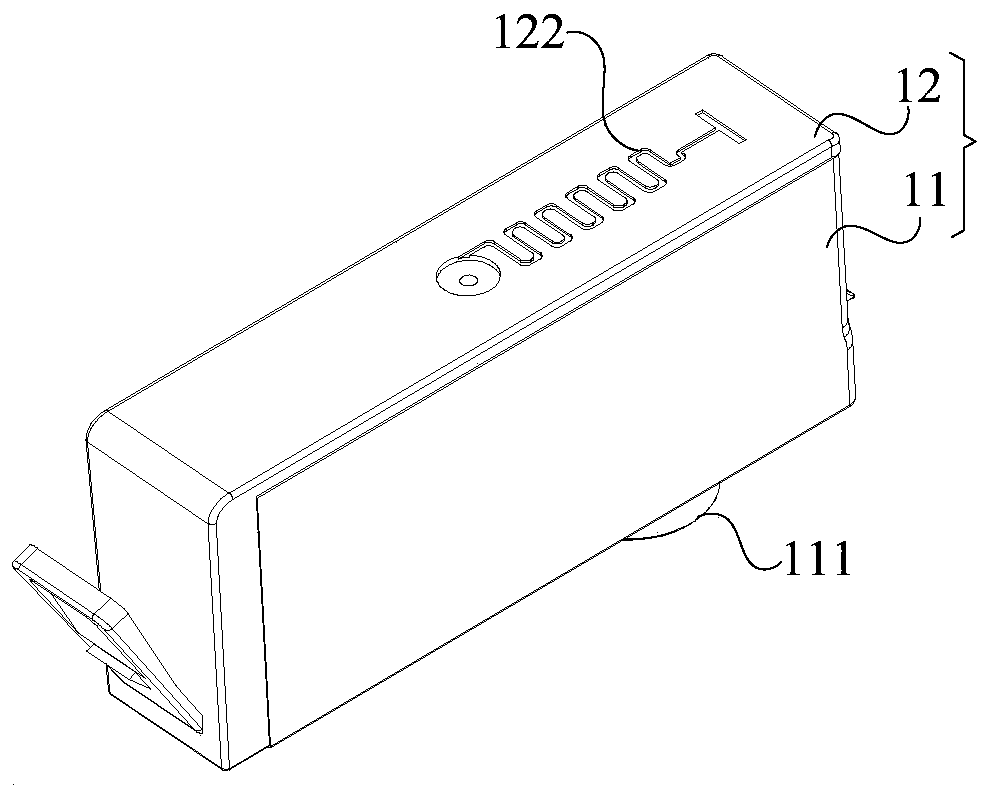

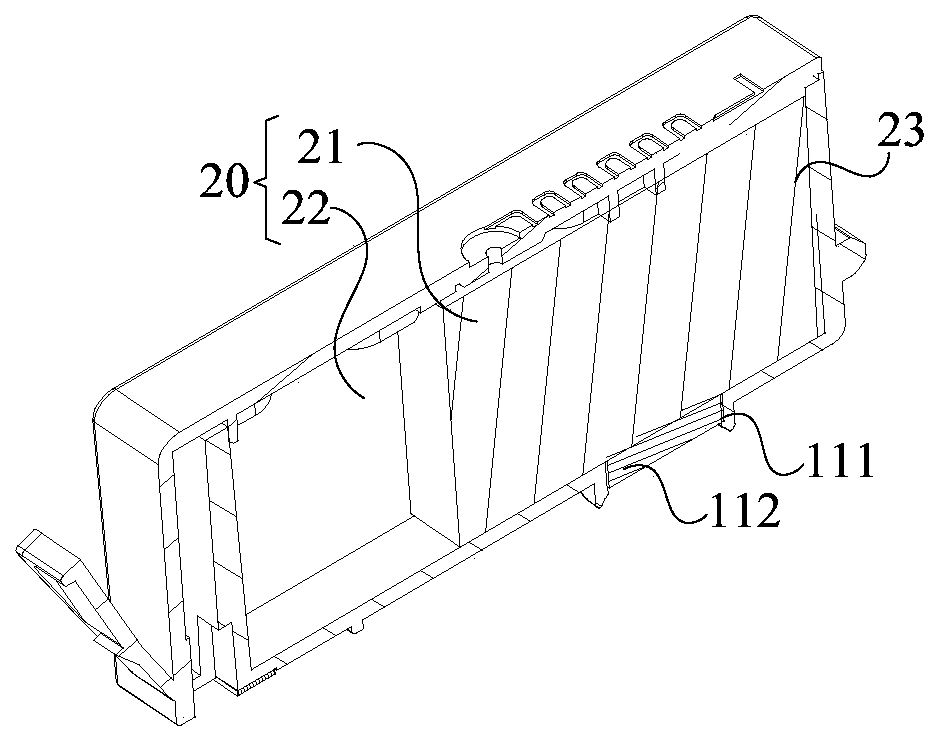

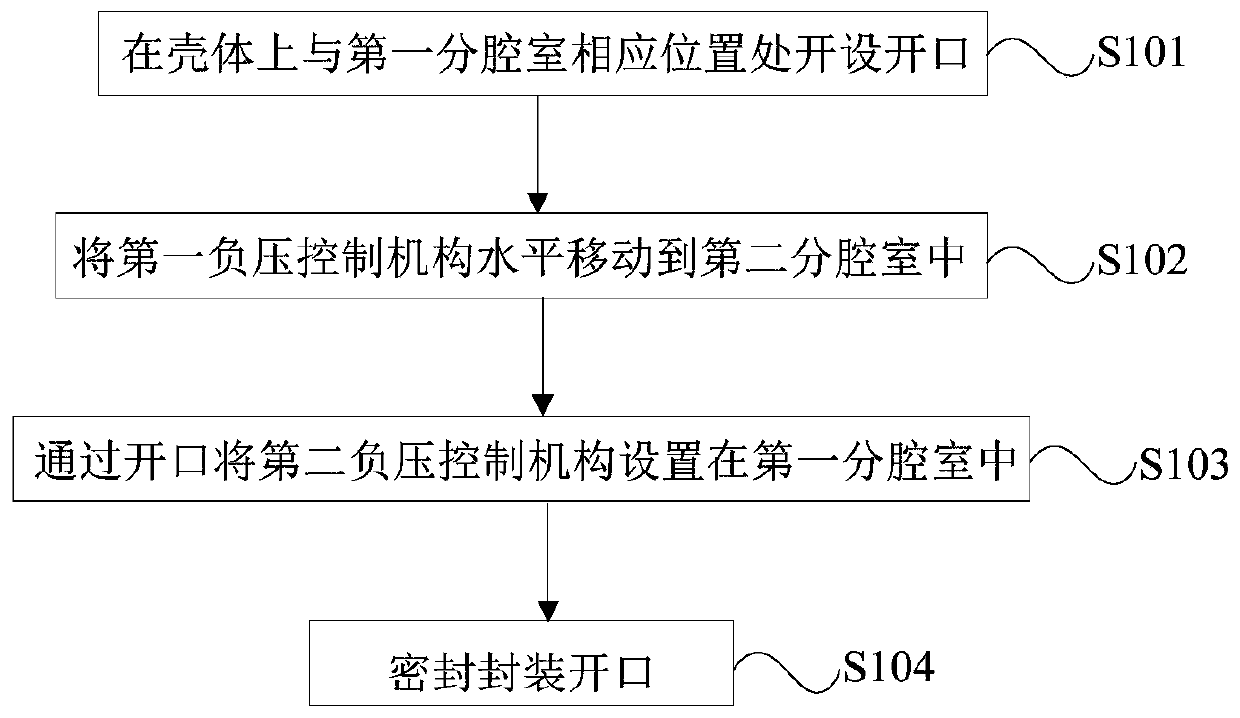

[0039] figure 1 It is a schematic diagram of the structure of an existing ink cartridge, figure 2 is a cross-sectional view of an existing ink cartridge, image 3 It is a schematic flowchart of a method for recycling ink cartridges provided in Embodiment 1 of the present invention, Figure 4 It is a schematic diagram of the opening and assembly of the opening in the ink cartridge recycling method provided in the first embodiment of the present invention, Figure 5 It is a schematic assembly diagram of the first negative pressure control mechanism in the ink cartridge recycling method provided in the first embodiment of the present invention, Image 6 It is an assembly schematic diagram of the second negative pressure mechanism in the ink cartridge recycling method provided in the first embodiment of the present invention.

[0040] Embodiment 1 of the present invention provides a method for recycling ink cartridges, such as Figure 4 and Image 6 As shown, the ink cartrid...

Embodiment 2

[0063] Figure 7 It is a schematic diagram before packaging of a recycled ink cartridge provided in the second embodiment of the present invention, Figure 8 It is a schematic structural diagram of a reclaimed ink cartridge after packaging according to the second embodiment of the present invention.

[0064] This embodiment provides a recycled ink cartridge obtained by using the ink cartridge recycling method provided in Embodiment 1, such as Figure 5 to Figure 8 As shown, the recycled ink cartridge includes a casing 10 and an ink storage chamber 20 located in the casing 10. Specifically, the casing 10 includes a bottom case 11 and a cover 12, and the bottom case 11 is a rectangular parallelepiped with an opening at one end. , the surface cover 12 is covered on the bottom case 11, and forms the ink storage chamber 20 with the bottom case 11. The ink storage chamber 20 is divided into adjacent first sub-chambers 21 and second sub-chambers 22, An ink outlet 111 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com