Printer external ink supply device

An ink supply device and printer technology, applied in printing, etc., can solve the problems of reducing the ink capacity of the external ink supply device of the printer, requiring extremely high processing precision in the light-transmitting area, and occupying the space of the ink chamber by the float, so as to simplify the external installation of the printer. The structure of the ink supply device, the effect of reducing the processing technology requirements and increasing the ink capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

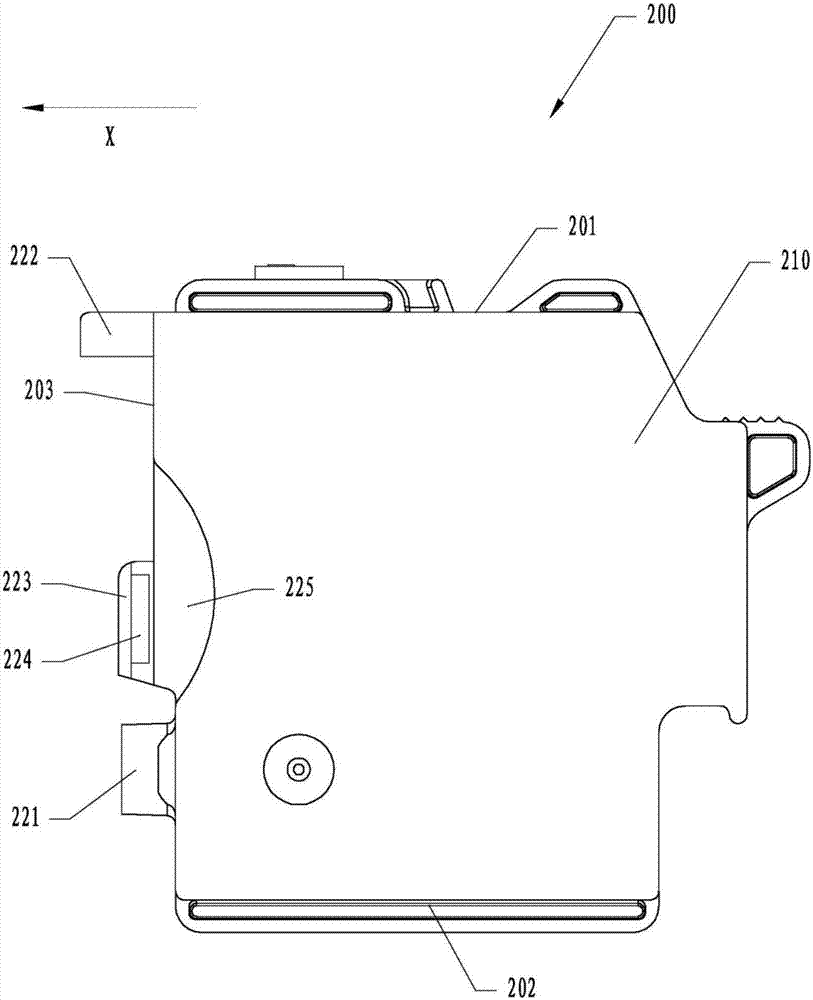

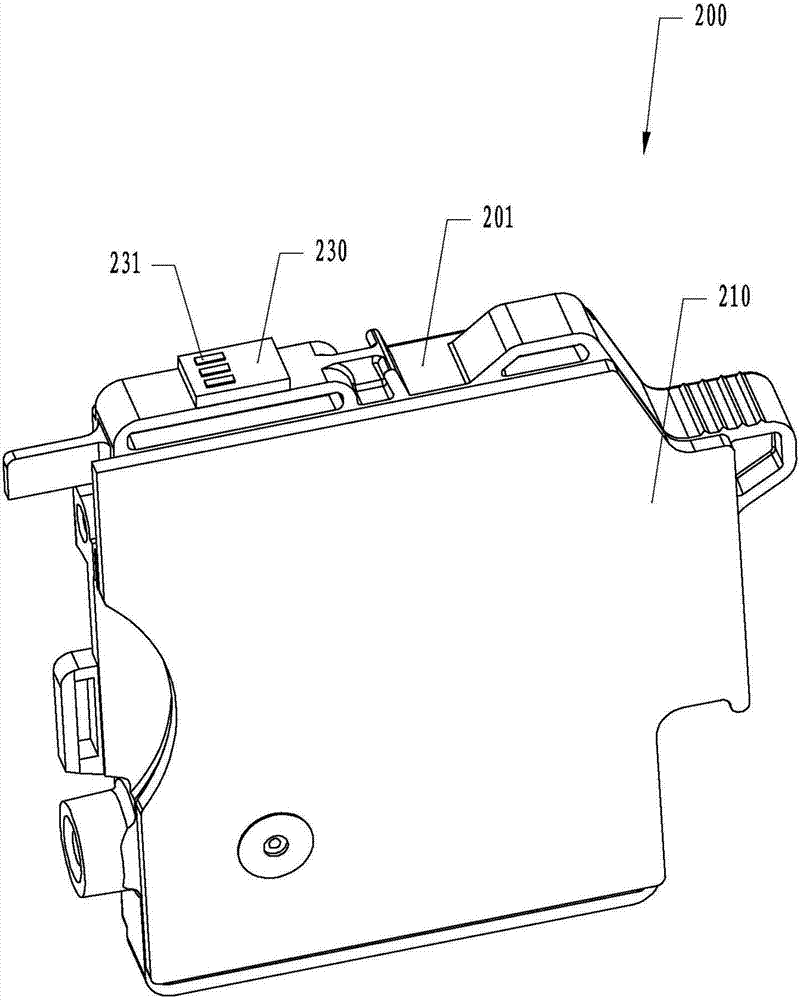

[0012] Such as figure 2 As shown, the direction X is the installation direction of the printer's external ink supply device 200 into the printer. The external ink supply device 200 of the printer has a casing 210 , and the casing 210 has a top wall 201 , a bottom wall 202 , and a front wall 203 . An ink outlet 221 is provided on the outside of the lower part of the front wall 203 , a first shielding part 222 is provided on the outside of the upper part, and a second shielding part 223 is provided on the outside of the middle part. A light-transmitting portion 224 is disposed between the second shielding portion 223 and the front wall 203 , and a third shielding portion 225 is disposed inside the middle of the front wall 203 . The first shielding part 222 is used to detect whether the ink supply device 200 external to the printer is installed in place. The thickness of the second shielding portion 223 along the direction X is used to determine the type of the ink supply dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com