Escape canopy structure and canopy separation bolt throwing method

A technology for separating bolts and cockpit covers, applied in aircraft parts, aircraft accessories, fuselage and other directions, can solve the problems of inability to effectively ensure the stealth performance of combat aircraft and the force transmission of the structure, poor stealth effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

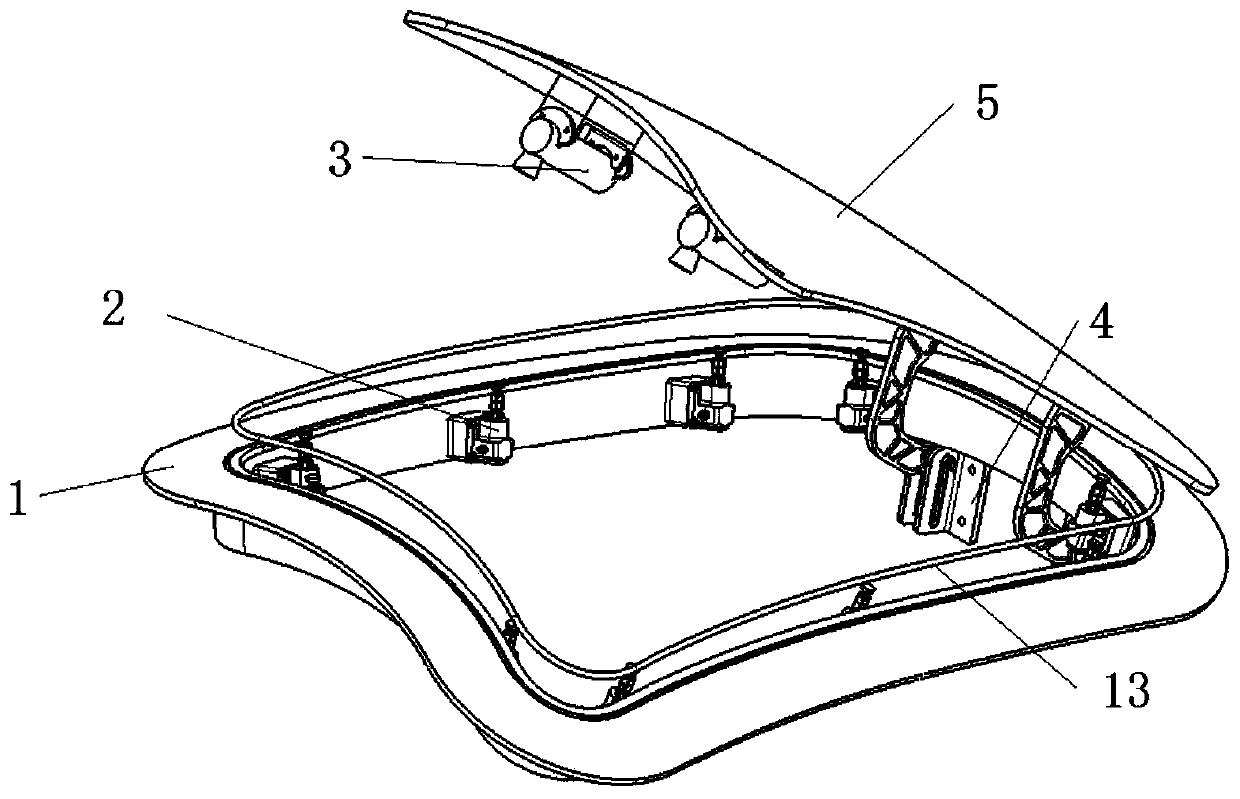

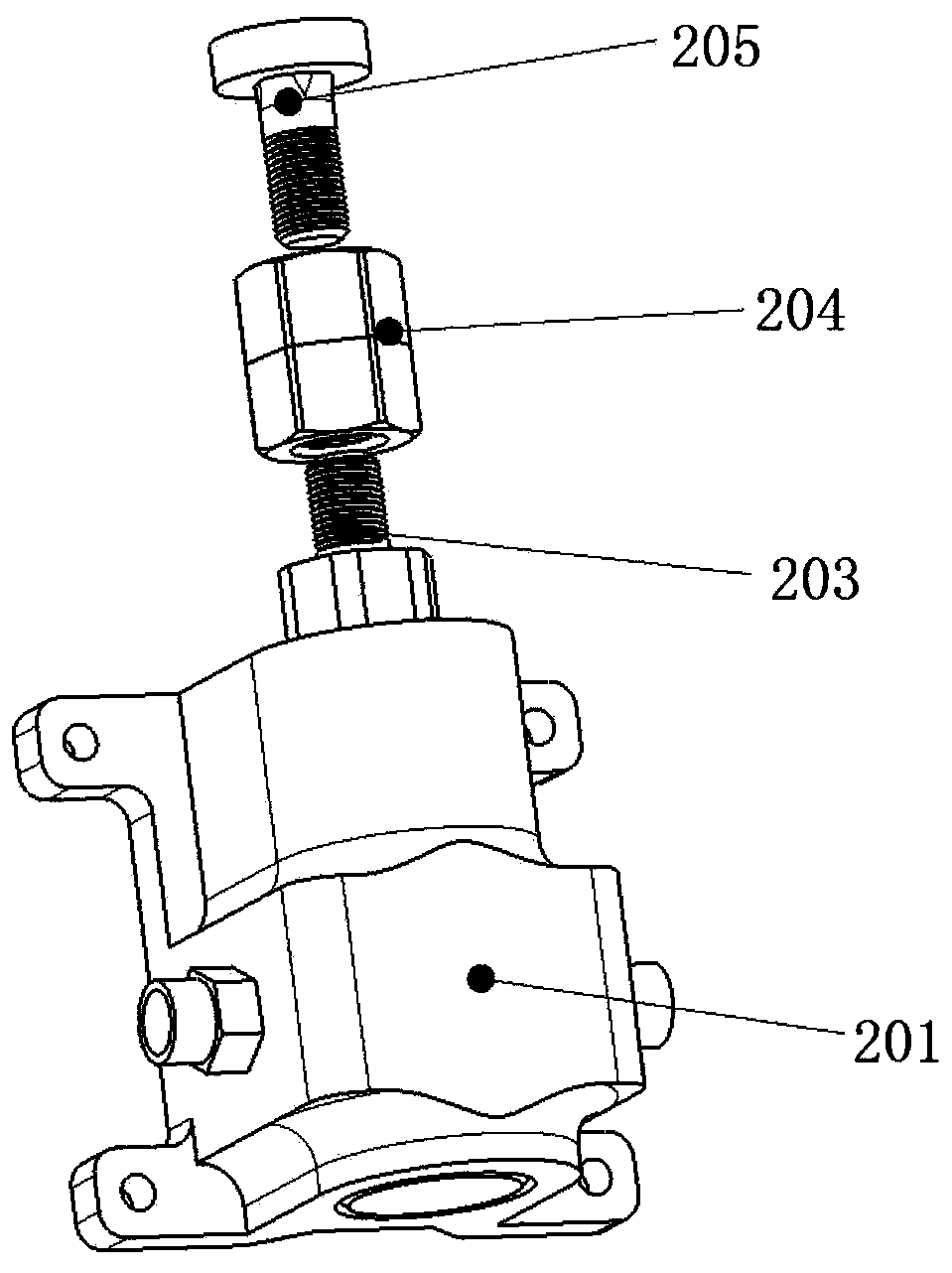

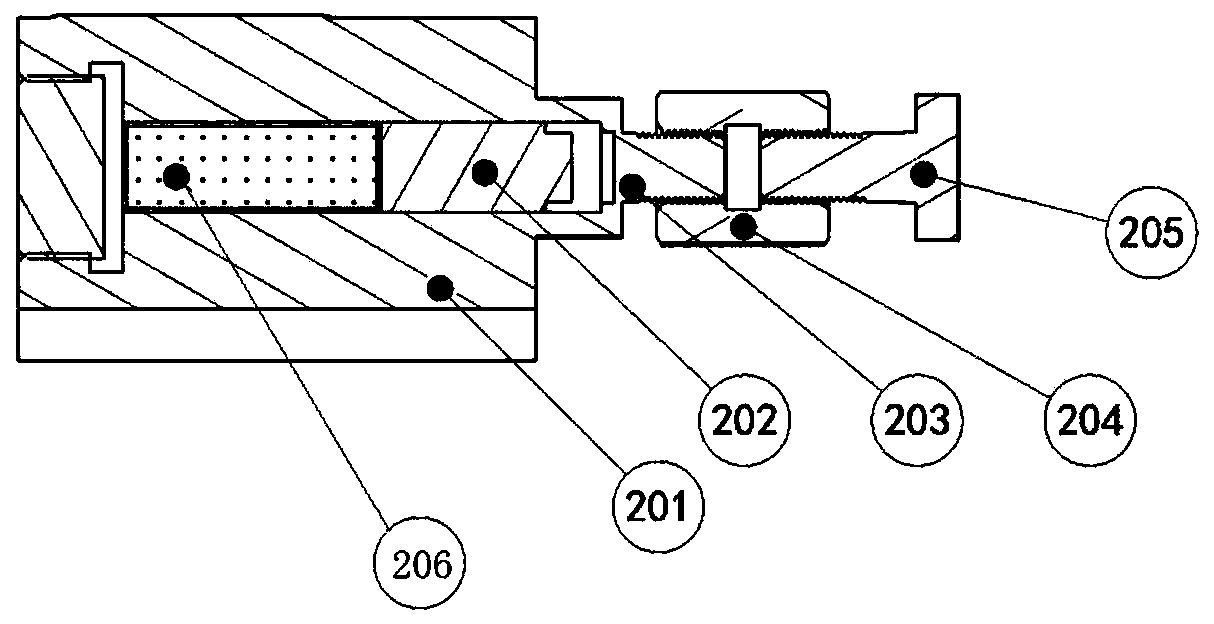

[0036] Such as figure 1 The shown escape canopy structure includes a hatch frame 1 with an integrated structure with the body, and the hatch frame 1 is an escape passage opened on the top of the body, and the escape passage is located in front of the driver in the body. At the same time, the edge of the escape channel extends vertically downwards to form a downward flange and then forms the hatch cover frame, which can ensure that the later separation bolt assembly 2 can be fixedly connected to the lower flange of the hatch cover frame, so as to facilitate the hatch The cover 5 is fixedly connected to the hatch cover frame through a separate bolt assembly 2, specifically, there are multiple separate bolt assemblies 2, which are evenly distributed on the flange of the hatch cover frame, so as to ensure the fixed connection of the hatch cover. When separating, the separation bolt assembly is separated at the same time; the hatch cover 5 that is sealed and connected to the hatch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com