Industrial production method of high-melt-strength polypropylene resin

A technology of high melt strength, polypropylene resin, applied in the field of expanded polypropylene material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

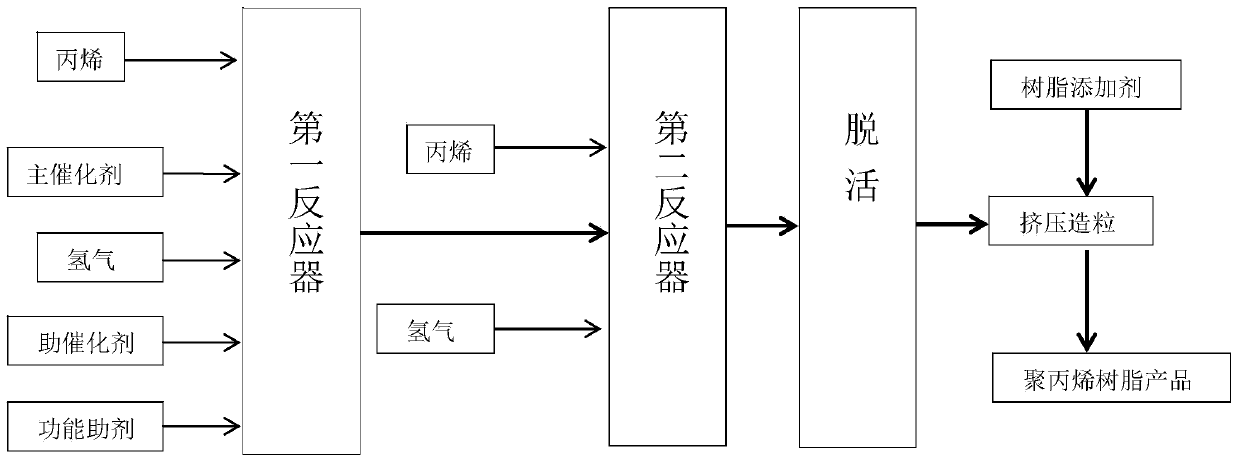

[0054] The polymerization reaction is carried out on the INEOS Innovene gas phase fluidized bed process unit. It mainly includes raw material refining unit, catalyst feeding unit, polymerization reaction unit and so on. The steps of the preparation method are as follows, see image 3 :

[0055] 1.1 Raw material refining:

[0056] The raw material propylene passes through the raw material refining system to remove water, COS and other reactive impurities.

[0057] 1.2 Feed of main catalyst, co-catalyst and functional additives:

[0058] The main catalyst, co-catalyst and functional auxiliary are all fed through the catalyst feeding unit.

[0059] The purchased commercial catalyst (Ziegler-Natta titanium series catalyst) was sprayed and injected into the reactor in the form of propylene entrainment through the feed pump.

[0060] Cocatalyst triethylaluminum, silane (specifically using DIBDMS), and functional additive (specifically using 7-octenyltrichlorosilane) are sprayed...

example 2

[0073] see Figure 4 , In this example, the production of high melt strength random copolymerized polypropylene resin is achieved by adding ethylene into two reactors. Since the addition of ethylene reduces the regularity of polypropylene molecular chains, it can adapt to downstream processing requirements. When producing high melt strength random copolymerized polypropylene resin, the specific production process control parameters of the two reactors are shown in Table 3.

[0074] Table 3. Process Control Parameters of High Melt Strength Random Copolymerized Polypropylene Resin

[0075]

[0076] Note: In the first reactor and the second reactor, the melt index (2.16Kg / 230°C) of the polymer is 1g / 10min and 2g / 10min respectively

[0077] Compared with example 1, the high melt strength random copolymerization polypropylene resin obtained by this example, because add ethylene as comonomer in two reactors, its physical property parameter and high melt strength homopolypropyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap