Oil drum carrying device

A technology for handling devices and oil drums, which is used in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve problems such as unstable center of gravity, reduced work efficiency, and oil drum damage, and can prevent random movement, improve work efficiency, The effect of stabilizing the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

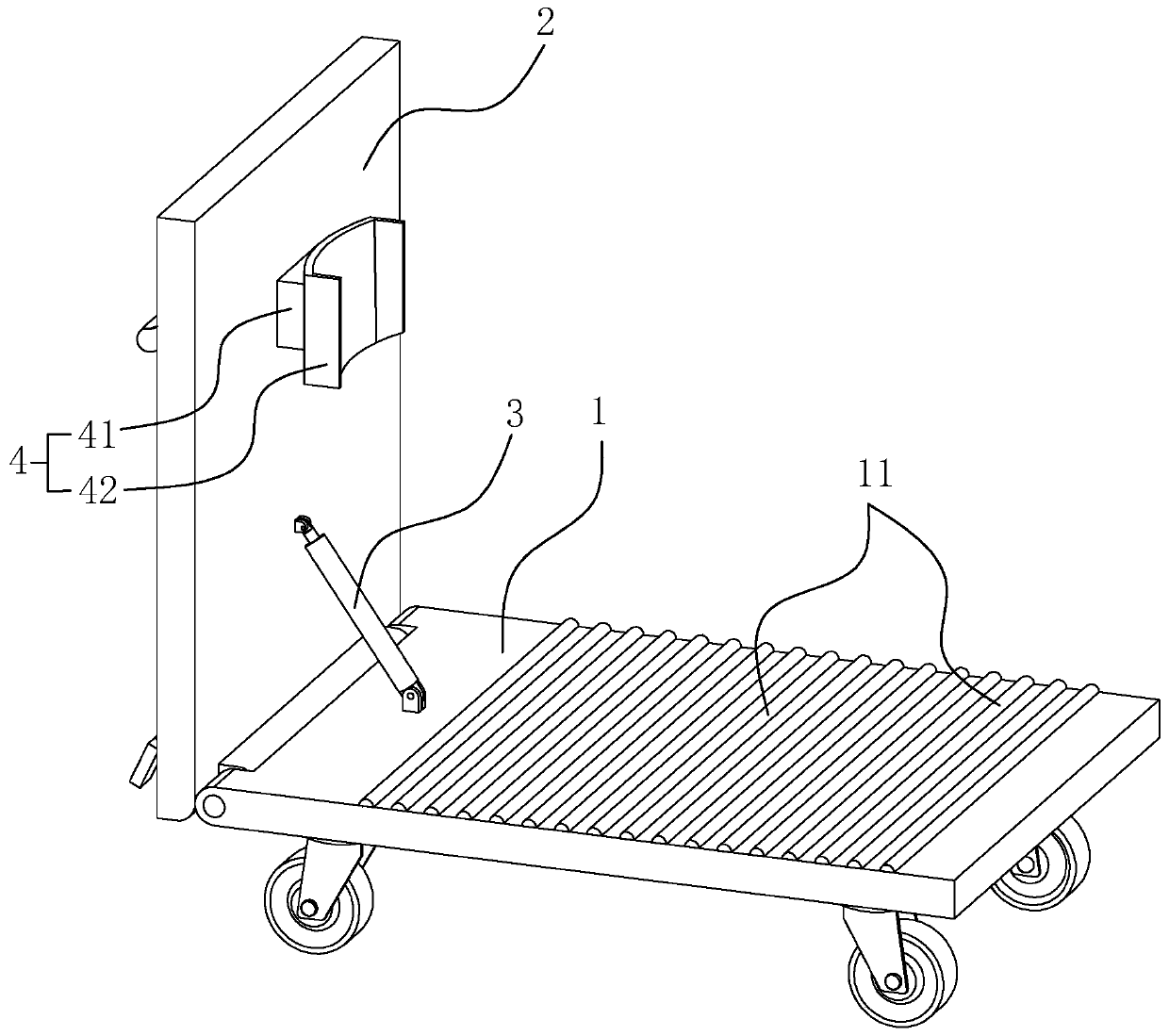

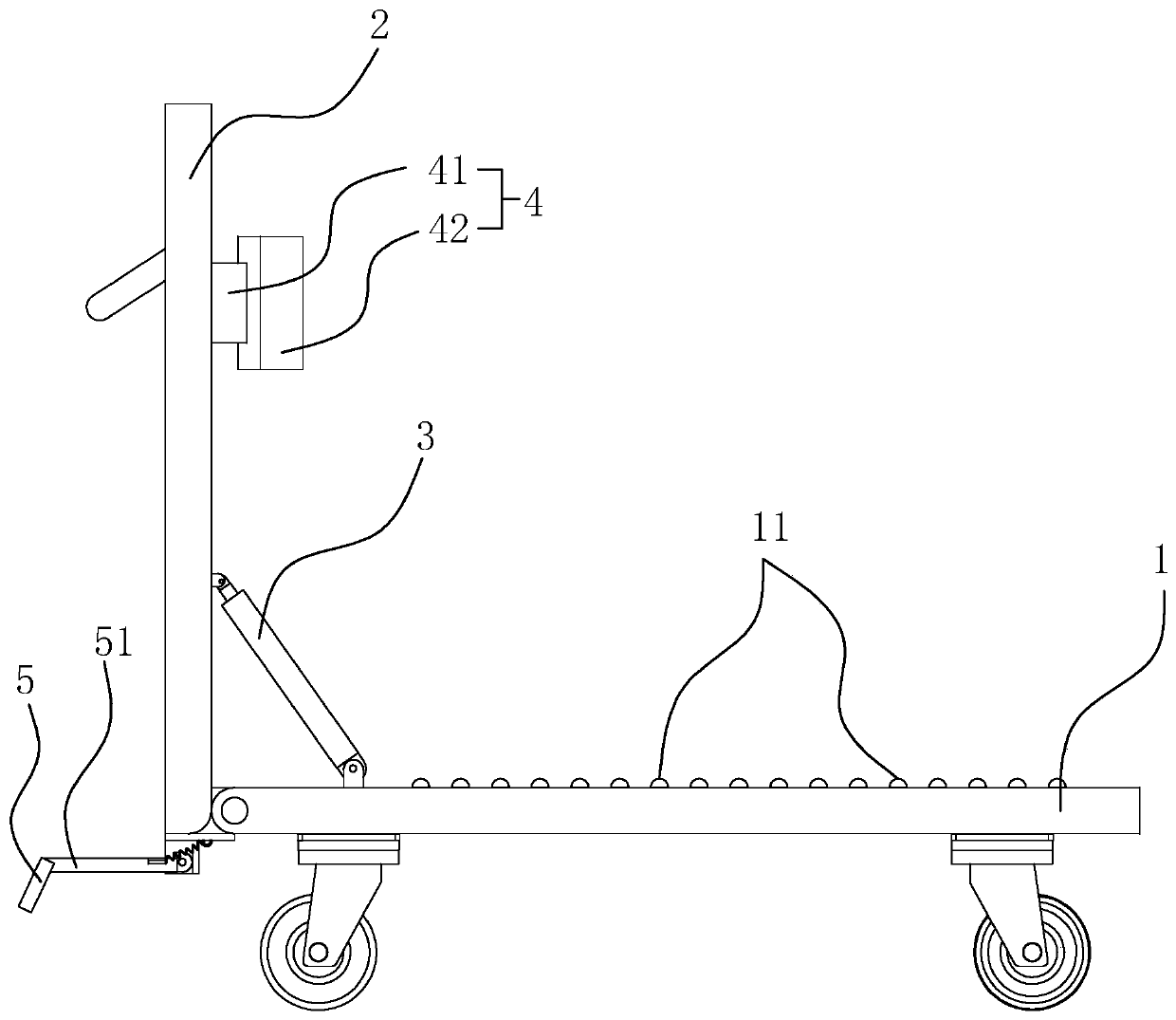

[0052] refer to Figure 6 and Figure 7 , there is a groove 21 on the support plate 2, the groove 21 is located above the connection between the control assembly 3 and the support plate 2, refer to Figure 8 Each of the two inner sides of the groove 21 is provided with an inward L-shaped chute 211, and the left and right sides of the connecting seat 41 are respectively provided with an L-shaped slider 411 used in conjunction with the chute 211, The top of the connection seat 41 is provided with a vertical plate 412 positioned in the groove 21, and the support plate 2 is provided with a plurality of threaded holes arranged side by side up and down. The fixed connection of the two threaded holes determines the up and down movement position of the vertical plate 412.

[0053] The implementation principle of this embodiment is: before the oil drum is transported to the device, according to the height of the oil drum and the amount of liquid in it, the support frame 4 is first di...

Embodiment 2

[0055] refer to Figure 9 and Figure 10 , the support plate 2 has a groove 21, the groove 21 is located above the connection between the control assembly 3 and the support plate 2, and an inward L-shaped chute 211 is formed on the two inner sides of the groove 21, connecting The left and right sides of the seat 41 are each provided with an L-shaped slide block 411, which is used in conjunction with the chute 211. The threaded hole provided on the top of the top 21 communicates with the groove 21, and a threaded rod 22 is inserted in the threaded hole. The end of the rod 22 is provided with a circular turning block 23, and the top of the connecting seat 41 has a circular groove 413 inwardly. The entry and exit in the threaded hole makes the rotary block 23 rotate in the circle 413 and controls the connecting seat 41 to move up and down in the groove 21 .

[0056] The implementation principle of this embodiment is: before the oil barrel is transported to the device, according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com