Stacker and power arm mechanism thereof

A stacker and power arm technology, applied in the field of logistics warehouse equipment, can solve the problems of large volume, poor stability and positioning effect, and achieve the effect of high accuracy, high precision, and reducing inertia and shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention provides a power arm mechanism of a stacker, and the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

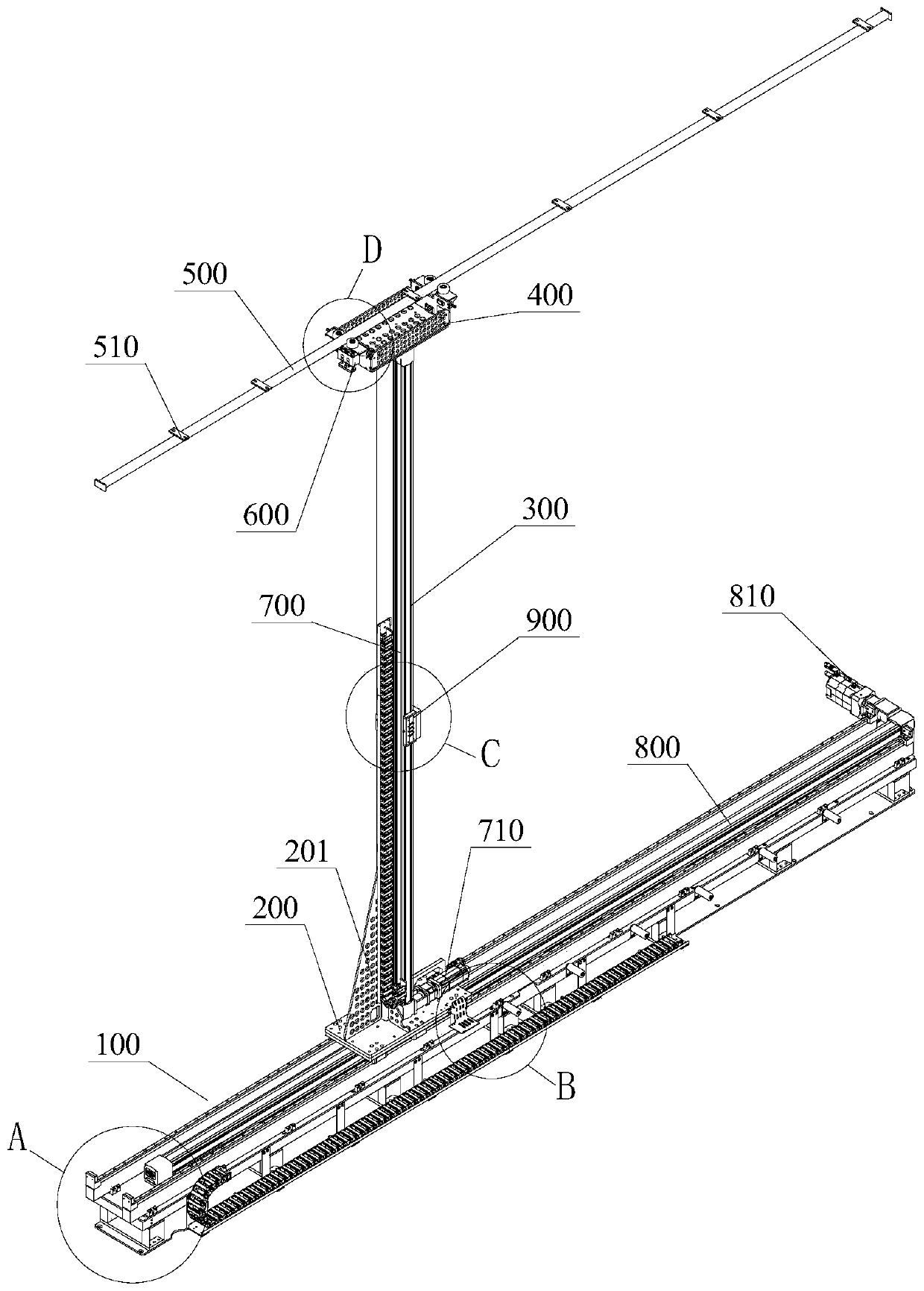

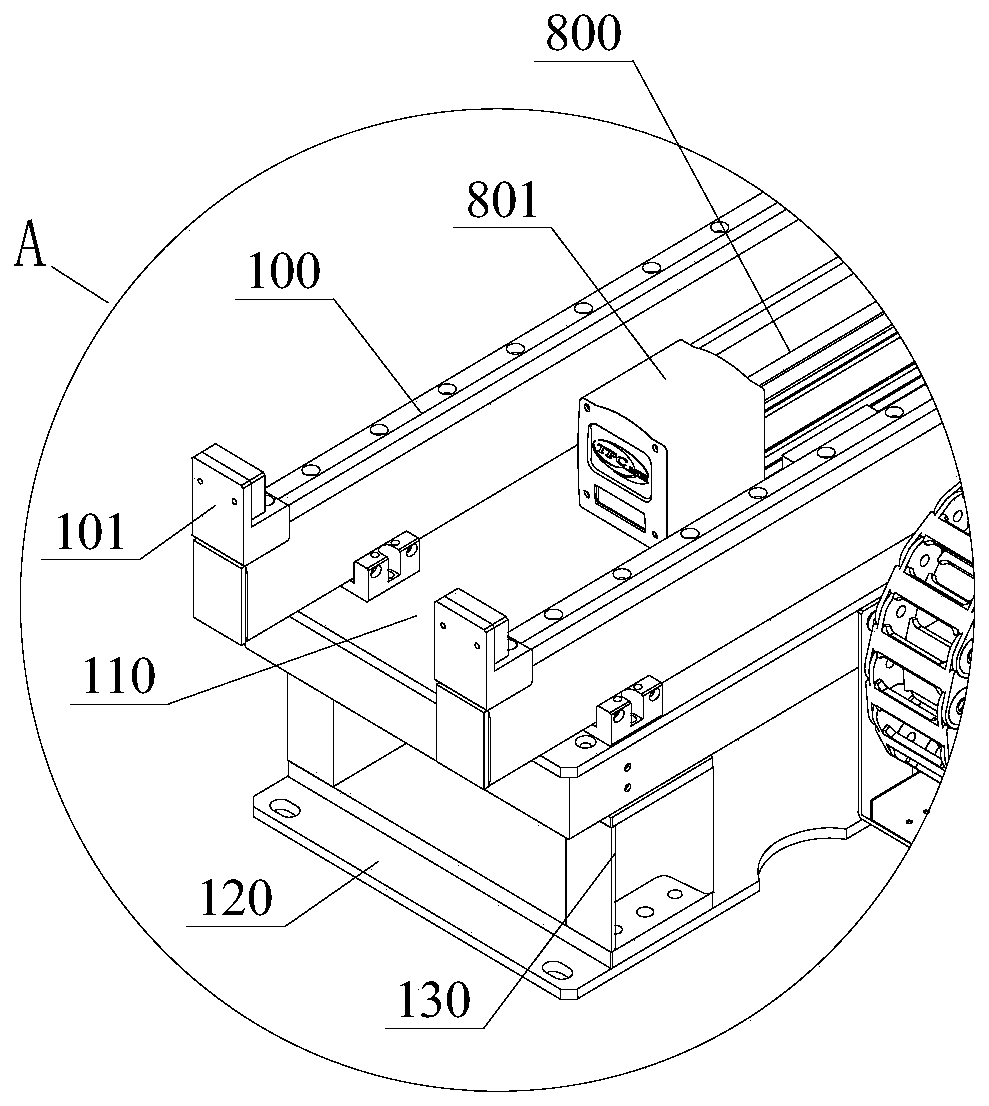

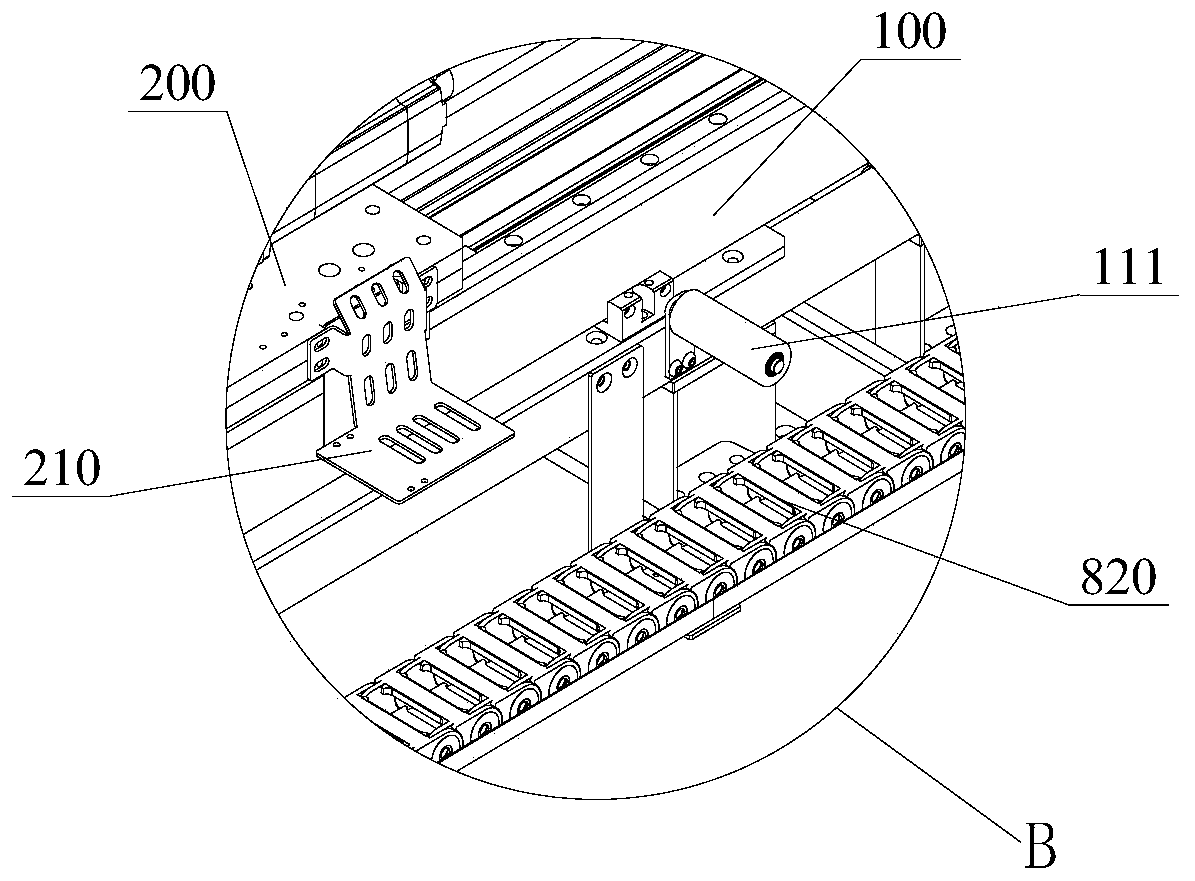

[0046] Such as figure 1 As shown, a stacker dynamic arm mechanism provided by the present invention includes a ground rail 100, a sky rail 500 and a transfer device placed between the sky rail 500 and the ground rail 100. The transfer device includes a transfer frame, a transfer Carrier module and floating connection mechanism 600. The transfer device moves between the sky rail 500 and the ground rail 100, and the sky rail 500 and the ground rail 100 limit its movement to prevent deviation from the predetermined track.

[0047]The transfer frame includes a mobile seat 200 slidably arranged on the ground rail 100, a mobile frame 400 slidably arranged on the sky rail 500, a column 300 is fixedly arranged between the mobile seat 200 and the mobile frame 400, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com