Centrifugal fan structure with variable volute tongue

A centrifugal fan and volute tongue technology, which is used in mechanical equipment, engine control, non-variable-capacity pumps, etc., can solve the problems of low fan efficiency and energy waste, and achieve the effect of improving operating efficiency and easy automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

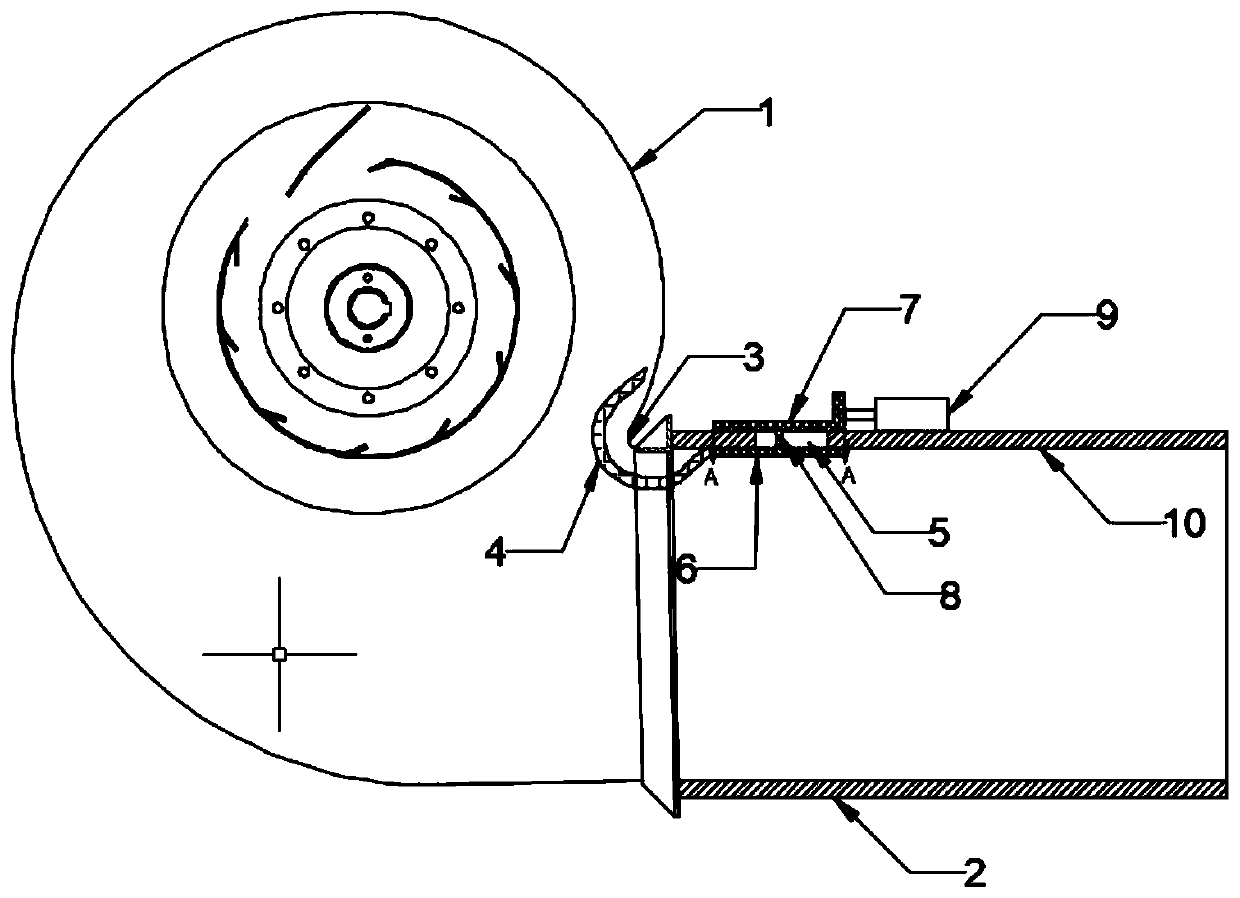

[0049] Implementation example 1: further, the driving device is an electric hydraulic cylinder 9, the push rod of the electric hydraulic cylinder 9 is welded to the outer sealing plate 7, and the telescopic direction of the push rod of the electric hydraulic cylinder 9 is parallel to the length direction of the air outlet 2.

[0050] The electric hydraulic cylinder 9 pushes the outer sealing plate 7 to move stably and reliably.

Embodiment 2

[0051]Implementation example 2: further, the driving device is a stepping motor 13, the stepping motor 13 is connected to the edge of the outer sealing plate 7 through a gear mechanism, the gear mechanism includes a rack 14 and a gear 15, and the rear side of the outer sealing plate 7 The edge is a tooth bar 14, and a gear 15 is welded on the rotating shaft of the stepping motor 13, and the tooth bar 14 and the gear 15 are meshed.

[0052] More precise by stepper motor 13.

[0053] Further, it also includes: a speed sensor 11, the speed sensor 11 is arranged on the shaft of the centrifugal fan body, the speed sensor 11 is connected to the controller 12 by wires; the controller 12, the controller 12 is connected to the drive device by wires. The rotational speed sensor 11 here can be a rotary encoder, and the controller 12 here can be a controller with peripheral circuits such as Arduino, Raspberry Pi, and PLC.

[0054] The rotational speed of the shaft of the centrifugal fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com