Blast hole charging auxiliary device and application method

An auxiliary device and blast hole charging technology, which is used in earth-moving drilling, open-pit mining, blasting, etc., can solve the problems of complicated operation process and long charging time, and achieves easy portability, low production cost, and the The complex effects of the drug process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In an open-pit mine, the blast hole is a deep hole with a depth of 14m, a blast hole diameter of 250mm, a charge length of 9.5m, a packing length of 4.5m, a drug delivery pipe diameter of 42mm, and a blast hole spacer length of 2m. Choose a density of 1.1g / cm 3 No. 2 rock emulsion explosive.

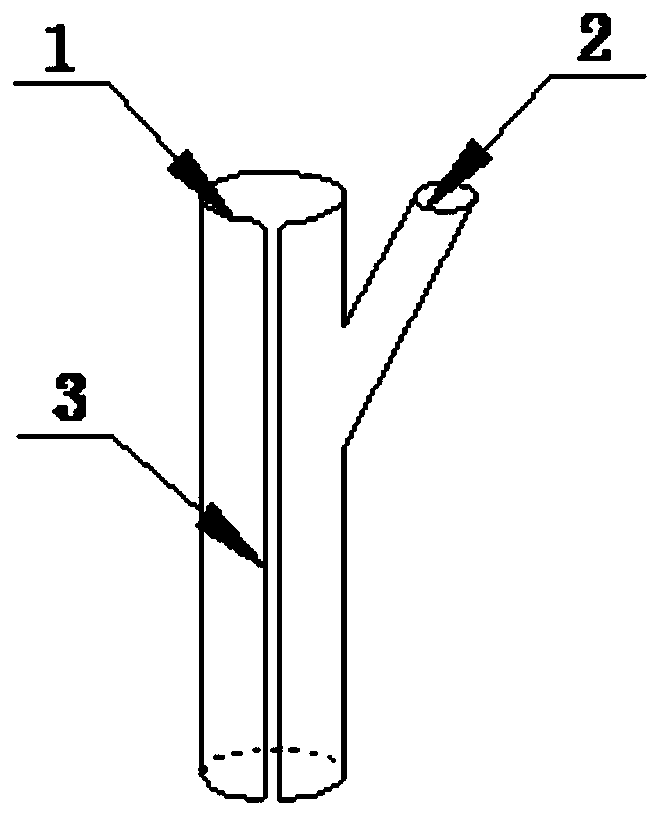

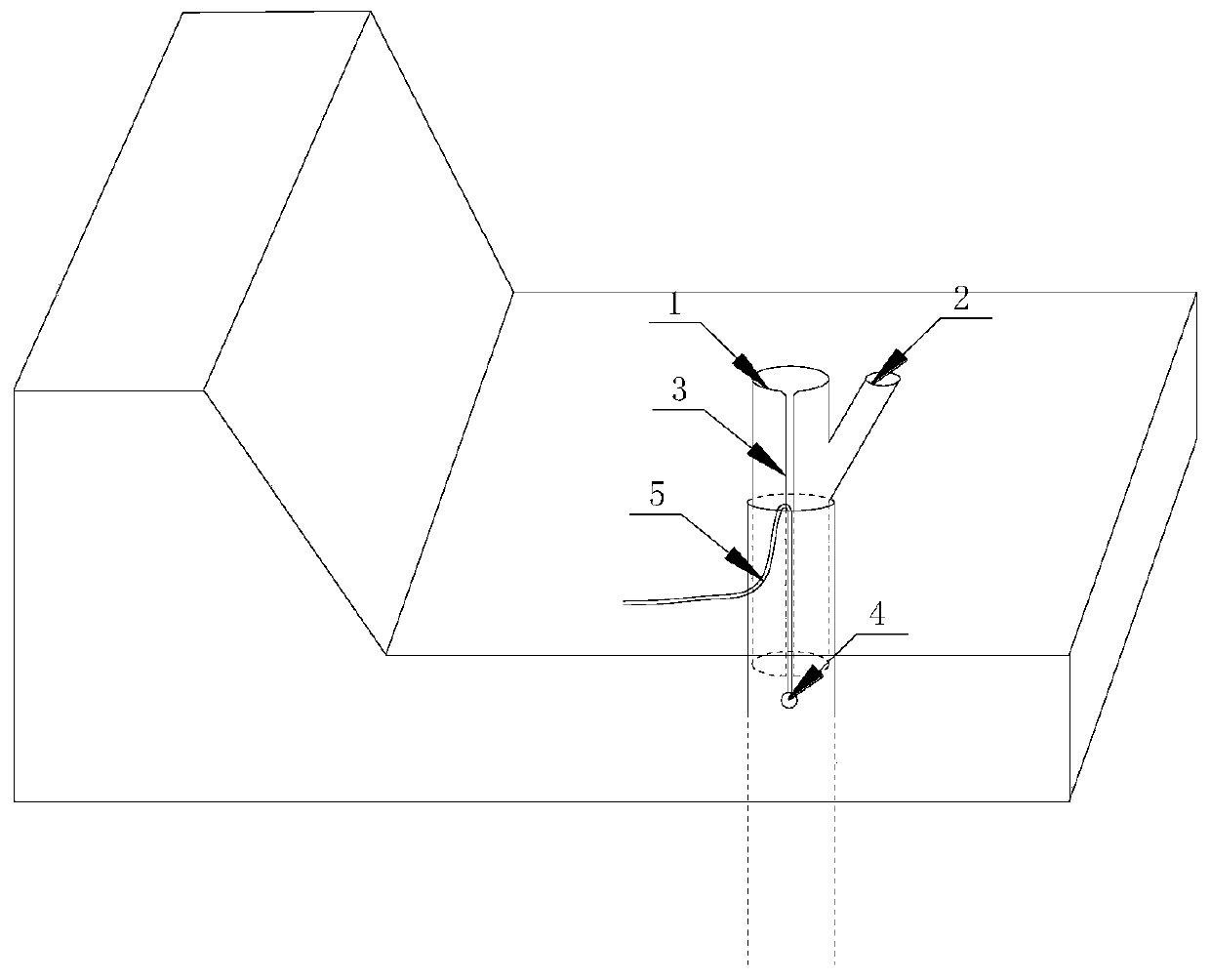

[0041] An auxiliary device for blasthole charging, comprising a standpipe 1 and a charge pipe 2, the charge pipe 2 is obliquely connected to the side wall of the standpipe 1, and the upper opening of the standpipe 1 and the upper opening of the charge pipe 2 are on the same horizontal plane On the side wall of the standpipe 1 there is an open slot 3 parallel to the axis, and the top of the open slot 3 is tapered from bottom to top.

[0042] The included angle A between the drug receiving tube 2 and the standpipe 1 is 30°.

[0043] The diameter of the medicine receiving tube 2 is 50mm, and the distance between its bottom and the top of the vertical pipe 1 is 100mm.

[0044] The ...

Embodiment 2

[0047] In an open-pit mine, the blast hole is a deep hole with a depth of 16m, a blast hole diameter of 300mm, a charge length of 10m, a packing length of 6m, a drug delivery pipe diameter of 40mm, and a blast hole spacer length of 1.5m. Choose a density of 1.3g / cm 3 Granular Ammonium Fuel Explosives.

[0048] An auxiliary device for blasthole charging, comprising a standpipe 1 and a charge pipe 2, the charge pipe 2 is obliquely connected to the side wall of the standpipe 1, and the upper opening of the standpipe 1 and the upper opening of the charge pipe 2 are on the same horizontal plane On the side wall of the standpipe 1 there is an open slot 3 parallel to the axis, and the top of the open slot 3 is tapered from bottom to top.

[0049] The included angle A between the drug receiving tube 2 and the standpipe 1 is 30°.

[0050] The diameter of the medicine receiving tube 2 is 50mm, and the distance between its bottom and the top of the vertical pipe 1 is 150mm.

[0051] T...

Embodiment 3

[0054] In an open-pit mine, the blast hole is a deep hole with a depth of 18m, a blast hole diameter of 310mm, a charge length of 11.8m, a packing length of 6.2m, a drug delivery pipe diameter of 45mm, and a blast hole spacer length of 2.5m. Choose a density of 1.1g / cm 3 No. 2 rock emulsion explosive.

[0055] An auxiliary device for blasthole charging, comprising a standpipe 1 and a charge pipe 2, the charge pipe 2 is obliquely connected to the side wall of the standpipe 1, and the upper opening of the standpipe 1 and the upper opening of the charge pipe 2 are on the same horizontal plane On the side wall of the standpipe 1 there is an open slot 3 parallel to the axis, and the top of the open slot 3 is tapered from bottom to top.

[0056] The included angle A between the drug receiving tube 2 and the standpipe 1 is 30°.

[0057] The diameter of the medicine receiving tube 2 is 60mm, and the distance between its bottom and the top of the vertical pipe 1 is 150mm.

[0058] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com