Object carrying assembly for power line repair

A technology for carrying components and electric power repairs, which is applied to sports accessories, overhead lines/cable equipment, lifting devices, etc., can solve problems such as difficult climbing, increased efficiency, and ignorance of the specific conditions of utility poles, and achieves wide applicability, The effect of increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

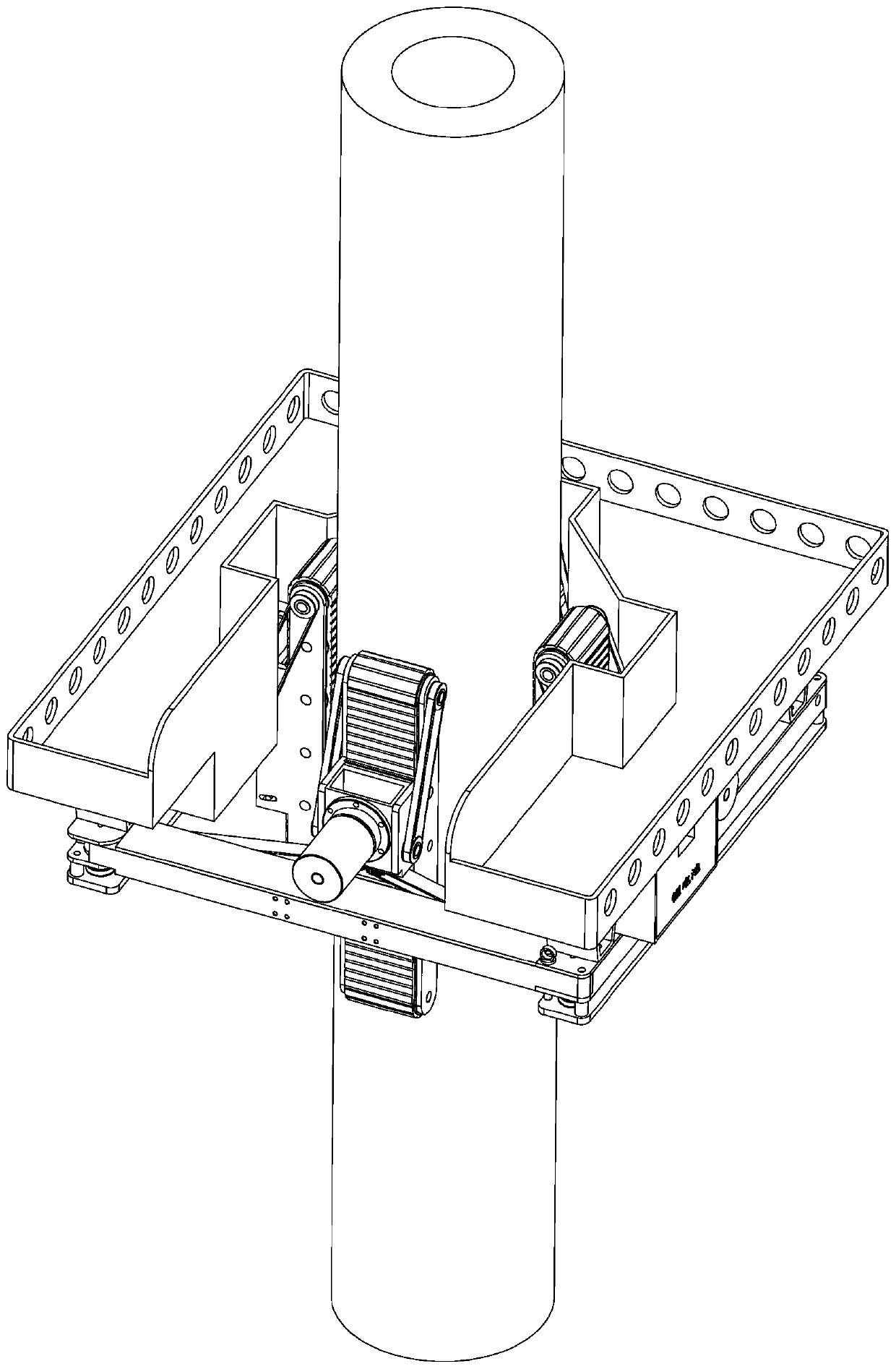

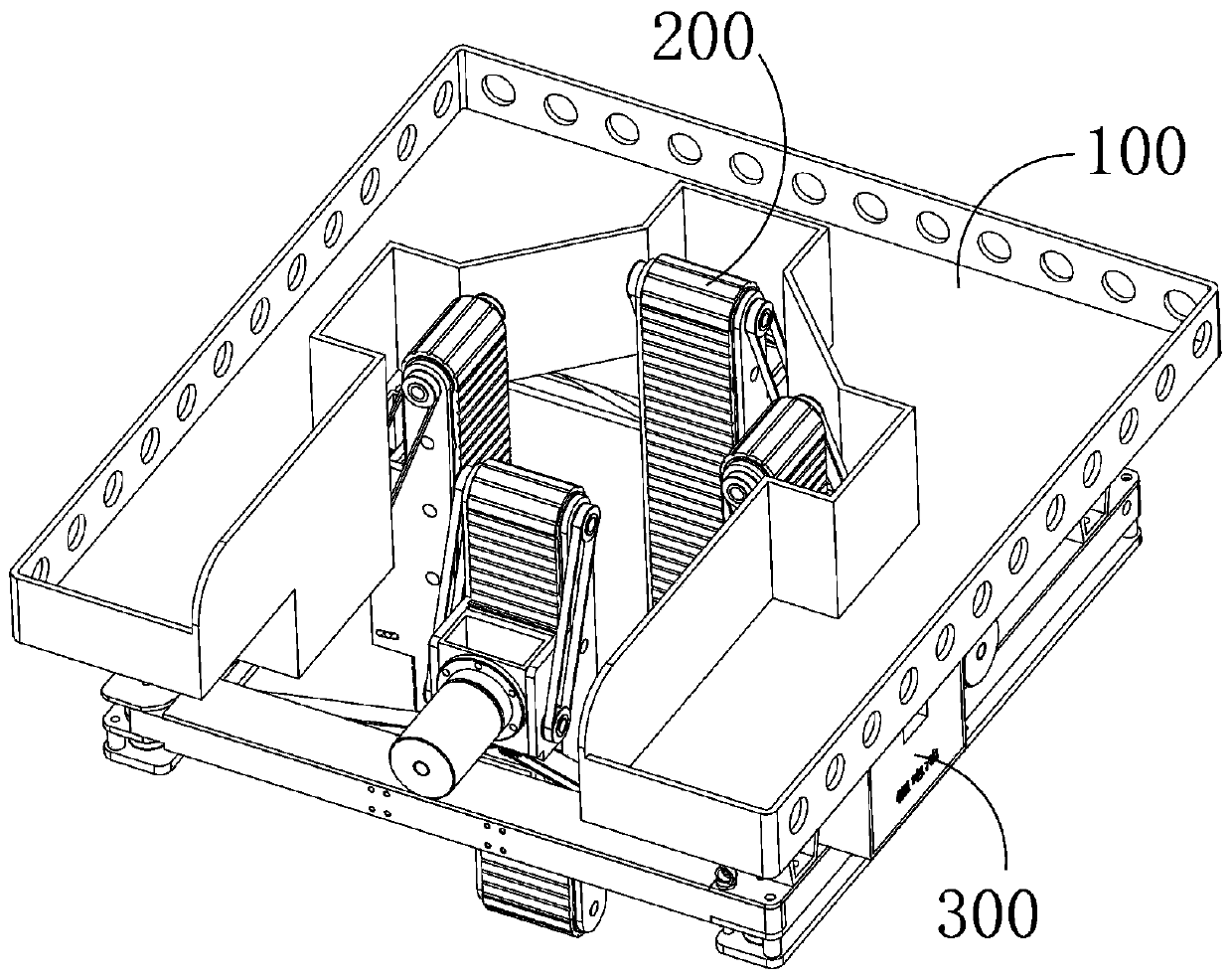

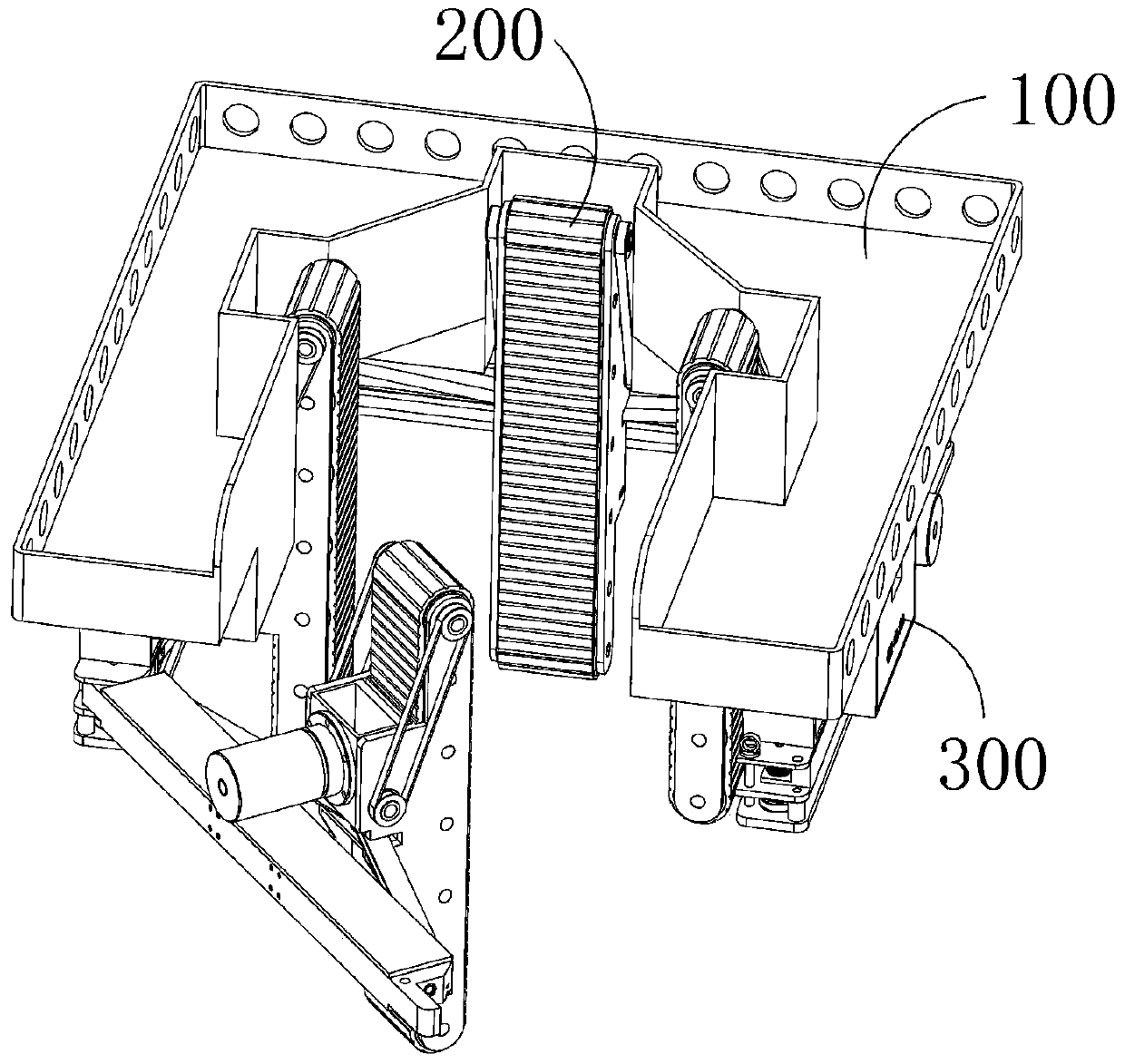

[0055] Automatic pole climbing equipment, which includes a main frame body 100 and an automatic pole climbing device 200 and a control device 300 installed on the main frame body 100. The automatic pole climbing device 200 is used to drive the whole transfer machine along the extension direction of the electric pole To carry out the lifting movement, the control device 300 is used to be manually controlled by the staff according to the actual situation and transmit the signal to the automatic pole climbing device 200 to make it operate according to the actual situation.

[0056] The main frame body 100 includes a supporting platform 101, a mounting bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com