Electronic truck scale anti-rollover device and anti-rollover method thereof

An anti-rollover and truck scale technology, applied in the field of truck scales, can solve the problems of deviation warning, scratching the car body, and lowering, and achieve the effects of improving accuracy and reliability, reducing climbing difficulty, and strong flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

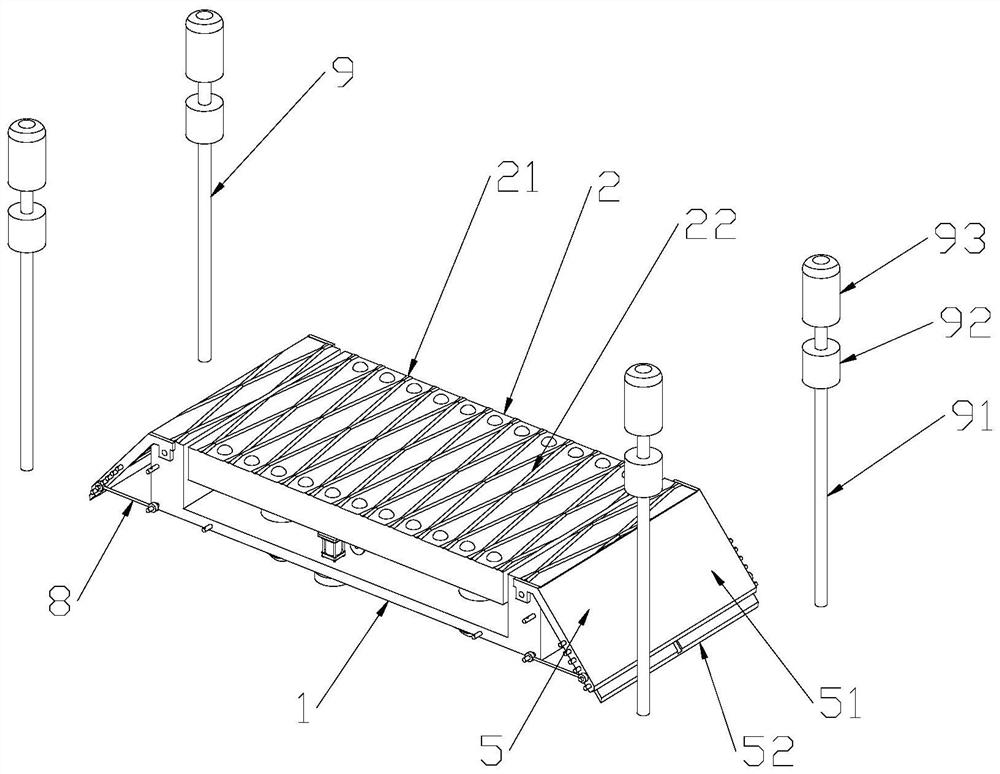

[0051] Warning member 9 comprises grating bar 91, as figure 1 As shown, the grating bar 91 is provided with a speaker 92, and the grating bar 91 is provided with a warning light 93, and the movement of the vehicle triggers the contact of the second control sheet 46 with the first control sheet 44 to send an early warning signal, and the warning light 93 and the speaker 92 simultaneously send out The early warning actively warns the vehicle to adjust the moving direction of the vehicle in time.

[0052] An electronic truck scale anti-rollover device and an anti-rollover method thereof, the anti-rollover method includes

[0053] S1. After parking, the motor 167 is started, and the rotating plate 51 is driven to rotate through gear transmission, and the angle of the rotating plate 51 is adjusted to make it touch the ground;

[0054] S2, the limit ring 82 at one end of the connecting rod 81 is set on the second support rod 164, the limit ring 82 at the other end of the connecting...

Embodiment 2

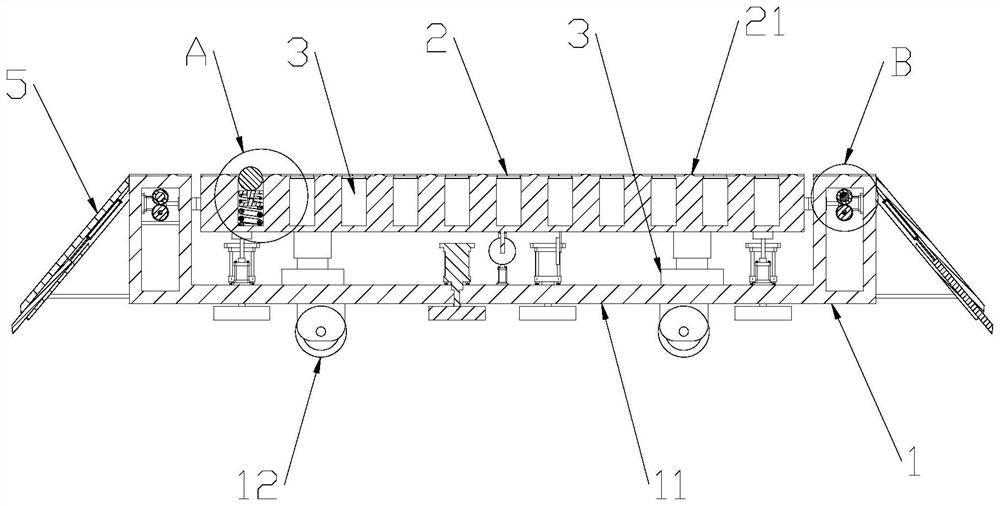

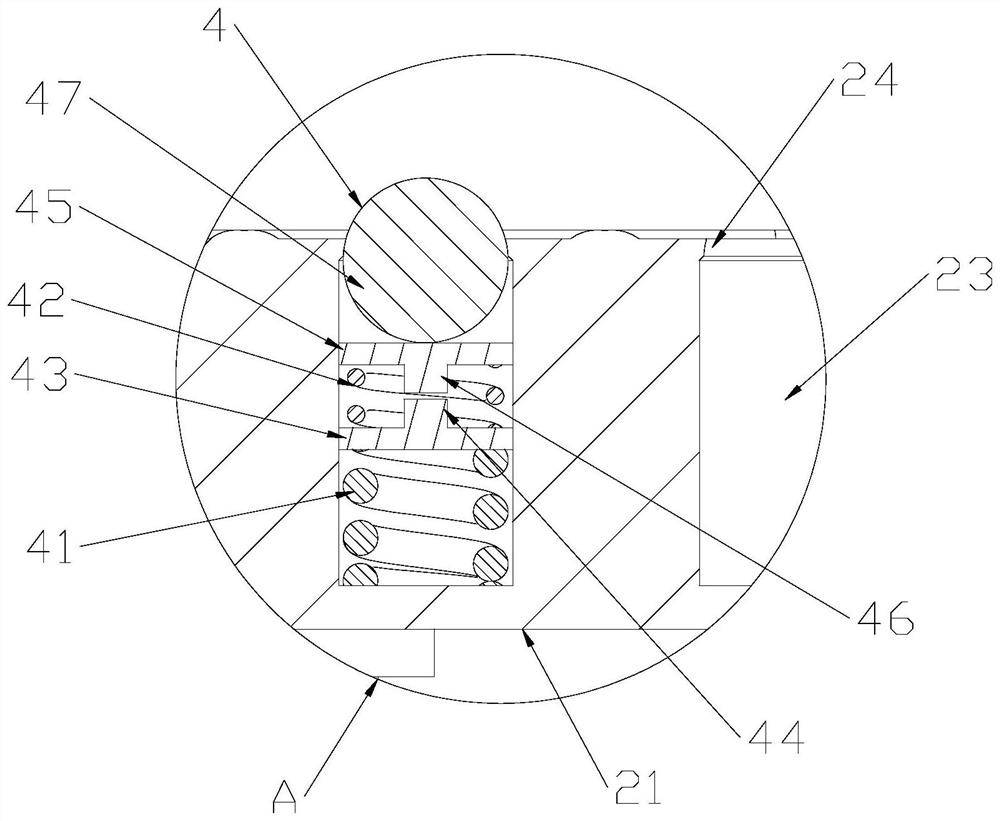

[0060] When the detection environment is complex, the output shaft of the first hydraulic cylinder 13 pushes the cushion block 131 to prop up the moving part 1, so that the power wheel 12 is separated from the ground, and the output shaft of the third hydraulic cylinder 17 moves down to separate from the early warning member 4, and the early warning The component 4 is always kept vertically downward under the action of gravity, and the light beams emitted by the first grating emitter 73 and the second grating emitter 74 are respectively irradiated on the first grating receiver 26 and the second grating receiver 27 to adjust the truck scale The main body 2 is balanced to ensure the accuracy of weighing data. When not in use, the output shaft of the third hydraulic cylinder 17 moves up and inserts into the limit position in the early warning component 4 .

Embodiment 3

[0062] Such as Figure 11 As shown, the first grating receiver 26 and the second grating receiver 27 both include two areas, one area is the receiving central area 261, and the other area is the deviation area 262. When the emitted light beam irradiates the receiving central area 261, At this time, the truck scale body 2 is in a horizontal state. When the emitted light beam irradiates the deviation area 262, the truck scale body 2 is in a non-horizontal state at this time, and the offset is calculated by an algorithm according to the receiving position of the radiation, and then through the corresponding The output shaft of the first hydraulic cylinder 13 pushes the block 131 to further adjust the moving part 1, thereby completing the balance adjustment of the truck scale body 2.

[0063] The anti-rollover device of the present invention has a deviation early warning function. When the vehicle deviates from the route on the truck scale body and reaches the warning line, the ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com