Crawler type shrub harvesting and bundling integrated machine

A crawler-type, all-in-one machine technology, applied in the direction of baler, harvester, baler, etc., can solve the problems of low supporting power, low work efficiency, high soil compaction, etc., to solve the problem of blockage, prevent overload blockage, The effect of preventing material entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

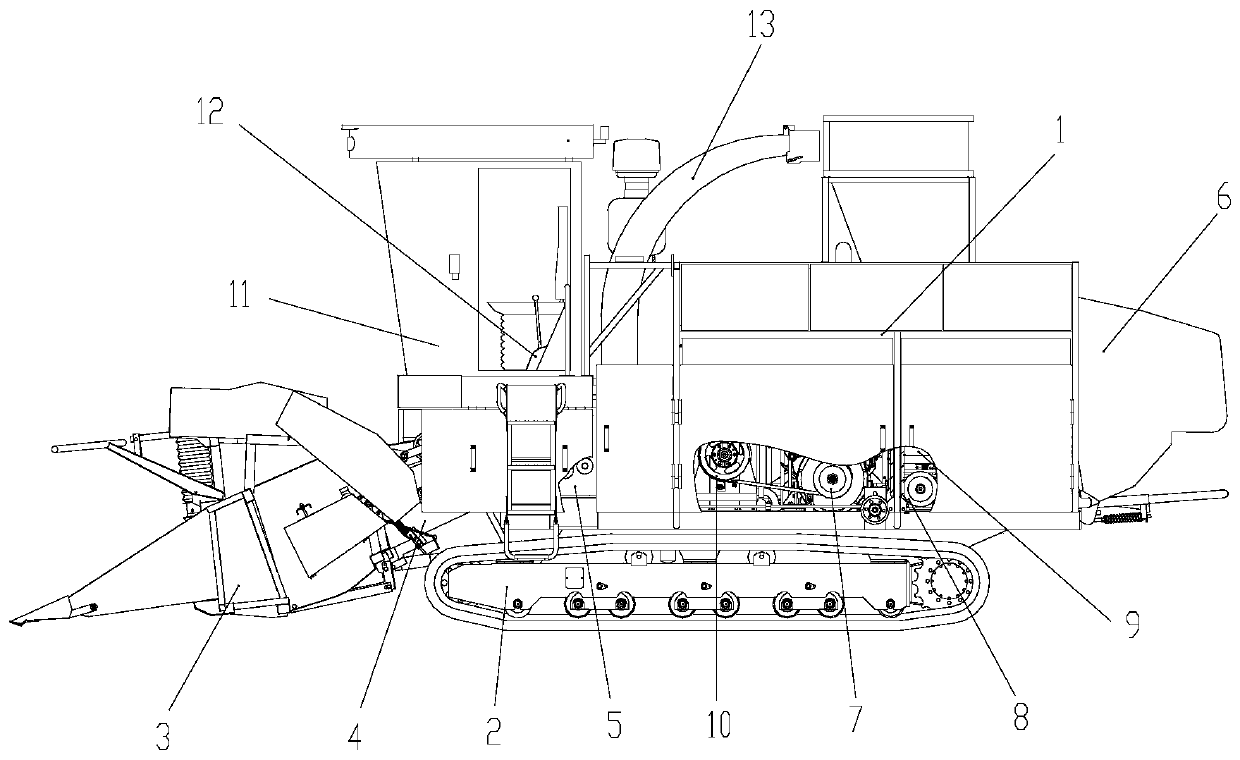

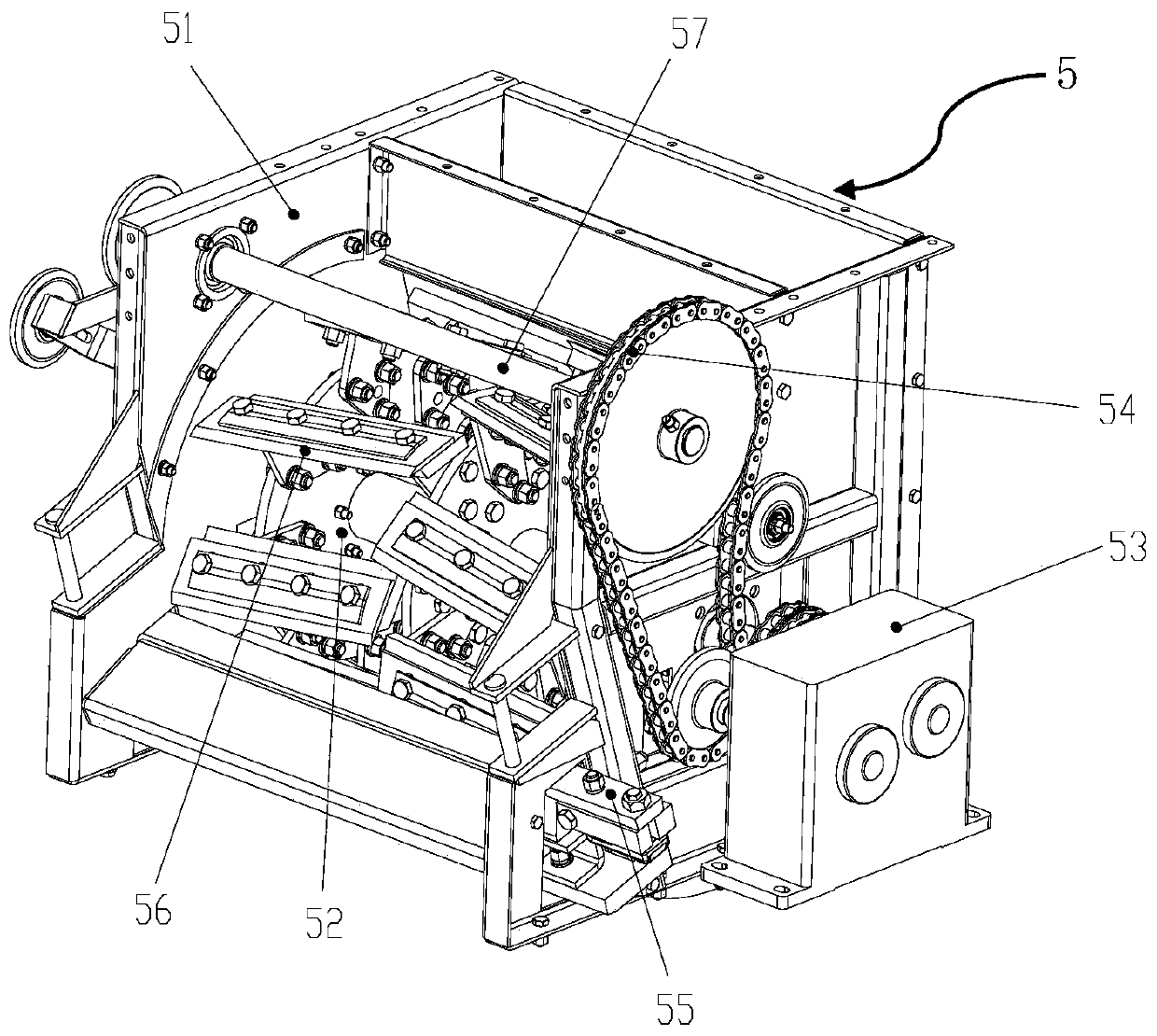

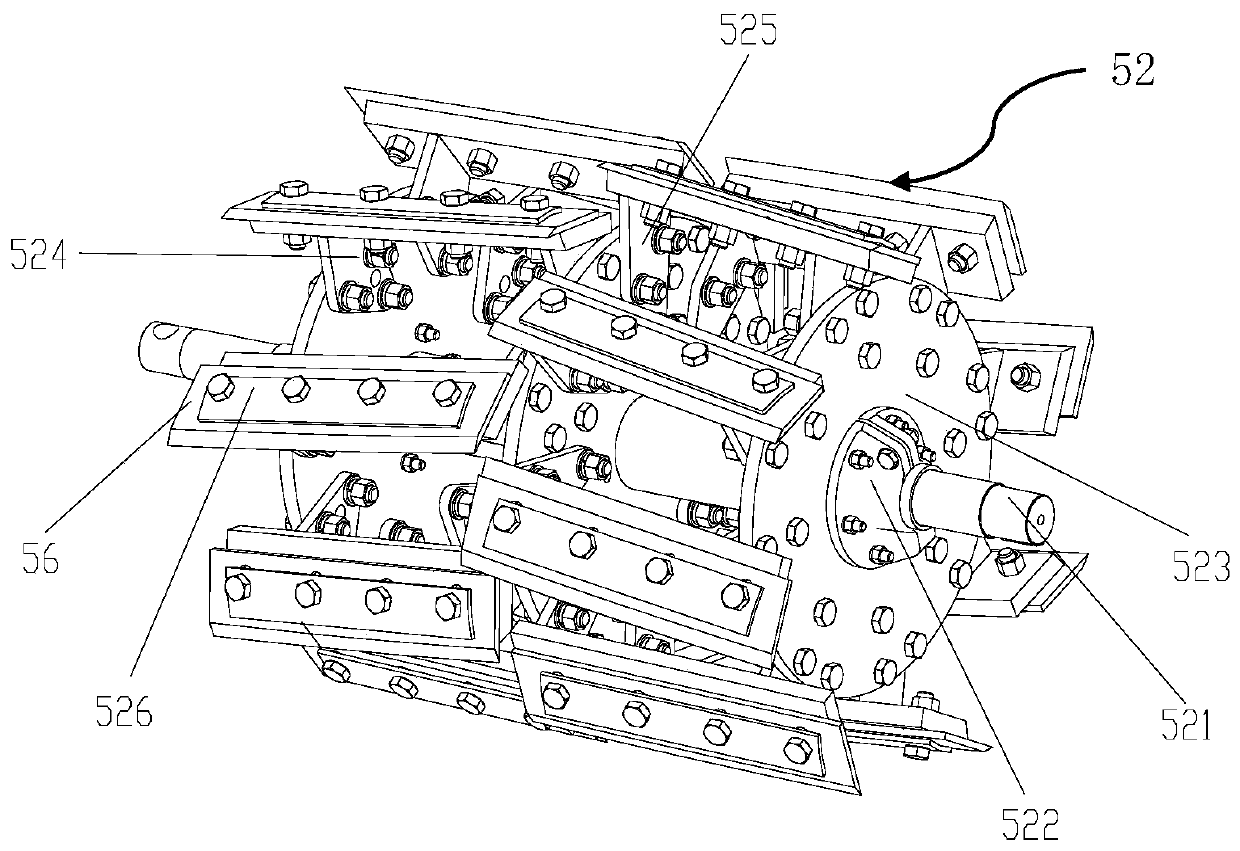

[0120] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the present invention. The crawler-type shrub harvesting and bundling integrated machine of the present invention can complete high-efficiency harvesting and high-density, high-efficiency bundling of shrub crops, and can realize continuous stubble cutting, forced feeding, graded chopping, and wind blowing without stopping the machine. Sending and throwing materials, even material conveying, top feeding, aggregate bundling, winding and cutting, and unloading operations can meet the needs of operations on the semi-sloping sandy land in the north and the muddy flat land in the south. The crawler shrub harvesting and bundling machine includes a frame 1, a crawler chassis 2, a header 3, a power drive device, a throwing device 13 and a bundling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com