Self-propelled bush harvesting and binding integrating machine

A self-propelled, all-in-one technology, applied in balers, harvesters, packaging, etc., can solve the problems of high transportation costs, affecting the economic benefits of planting farmers, and difficulty in mechanized harvesting of shrubs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

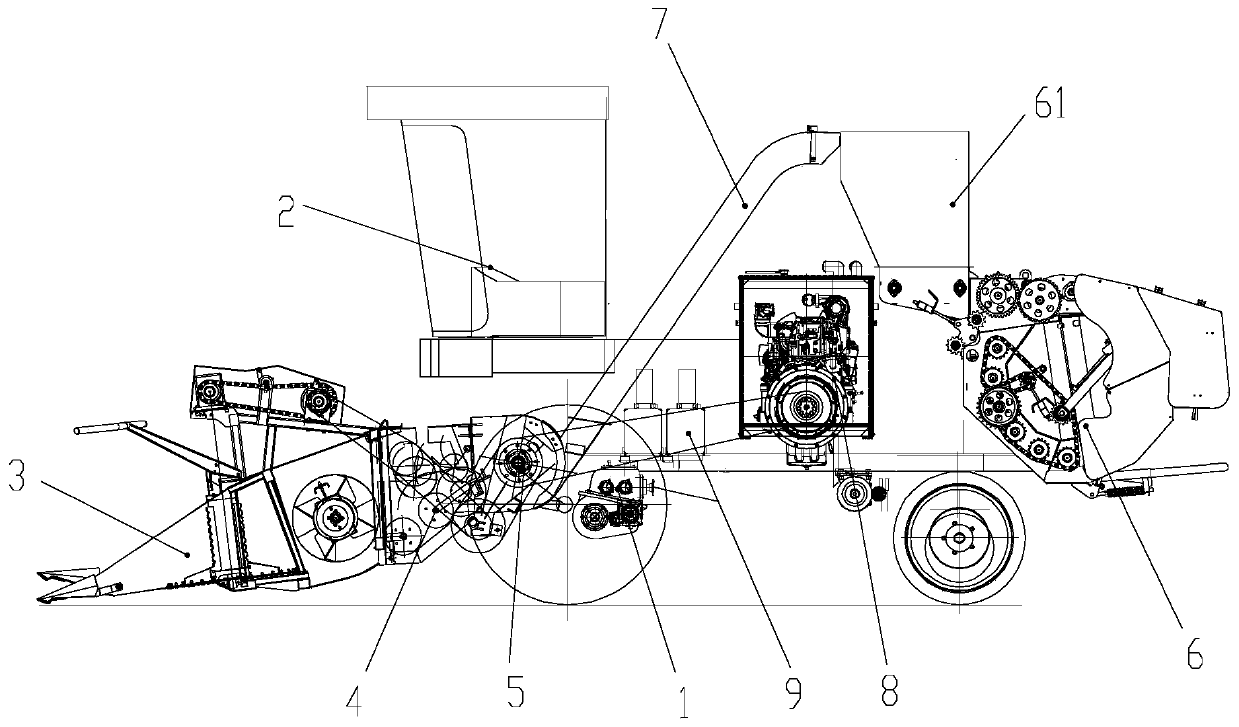

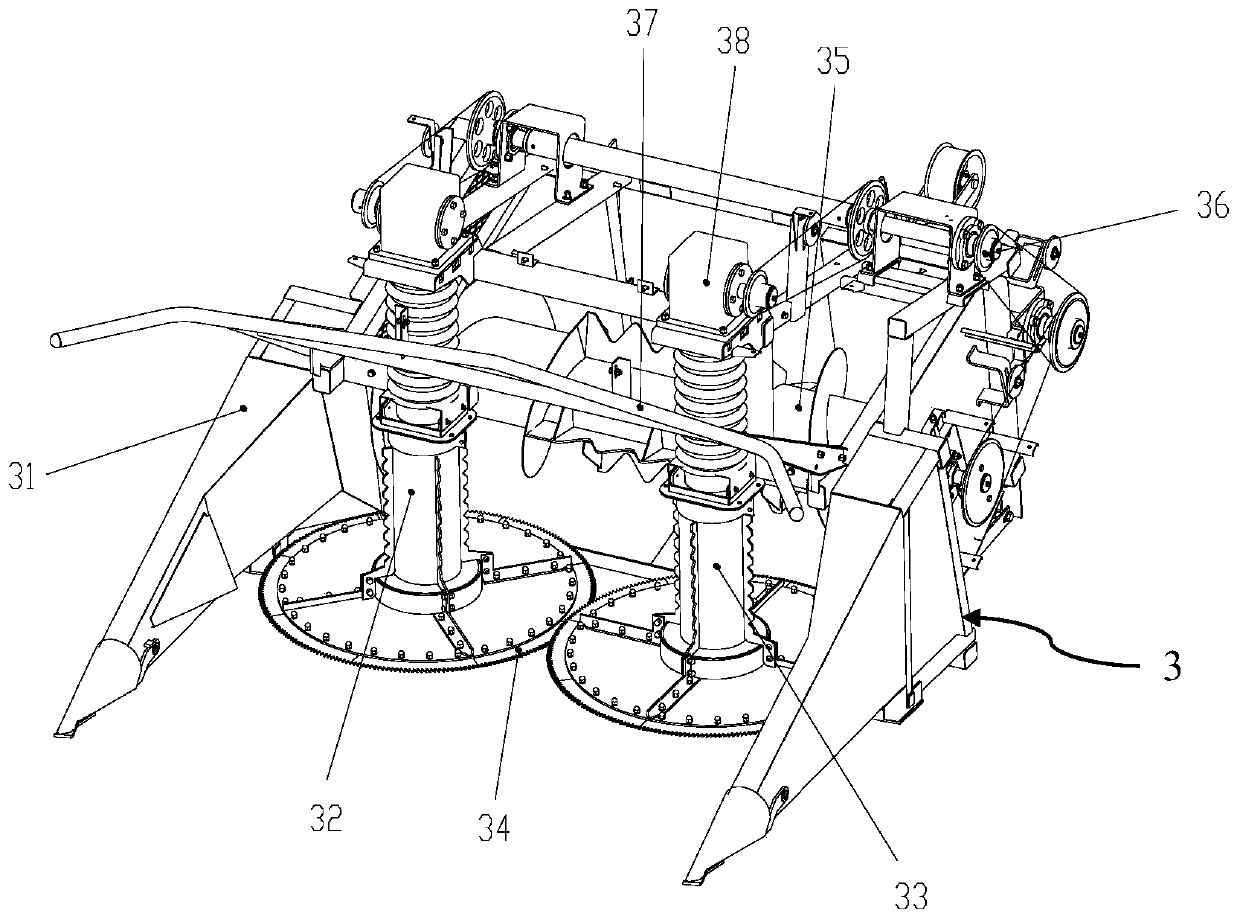

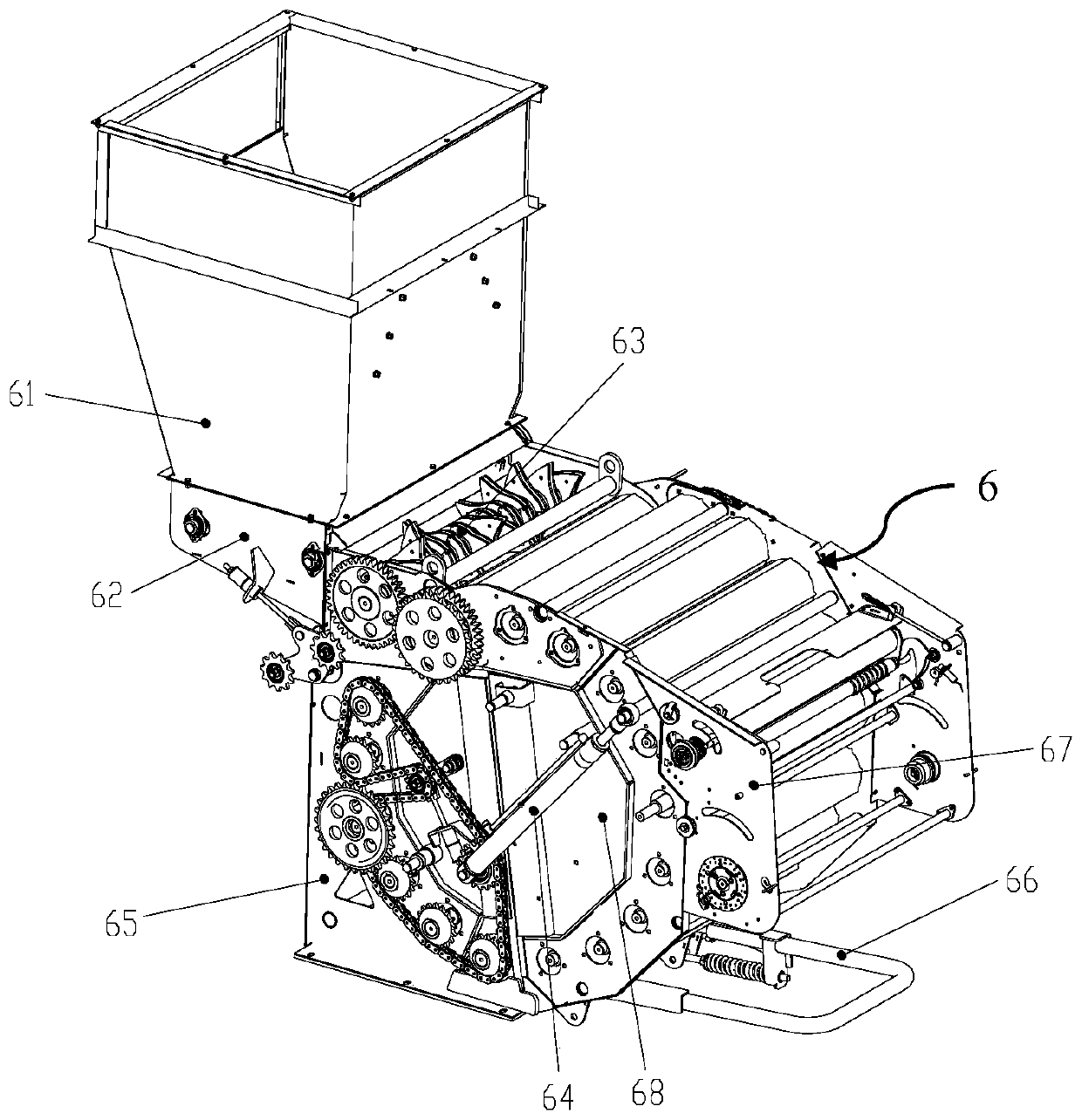

[0055] see figure 1 , figure 1It is a structural schematic diagram of a self-propelled shrub harvesting and bundling machine according to an embodiment of the present invention. The self-propelled shrub harvesting and bundling integrated machine of the present invention includes a self-propelled chassis 1, a harvesting platform 3, a forced feeding device 4, a chopping device 5, a throwing device 7, a round baling device 6 and a power drive device. A driving platform 2 is arranged above the self-propelled chassis 1, the forced feeding device 4 is arranged below the driving platform 2, the harvesting platform 3 is hooked on the front end of the forced feeding device 4, and the cutting The crushing device 5 is connected to the rear end of the forced feeding device 4, the throwing device 7 is located above the rear of the shredd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com