Method for preparing quick-frozen retrogradation cooked rice

A production method and anti-aging technology, which is applied in food science and other fields, can solve the problems that the anti-aging ability of rice cannot be greatly improved, and achieve the effects of improving anti-retrogradation ability, preventing retrogradation, and delaying starch retrogradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The anti-retrograde rice material includes the following raw materials and their weight fractions: 30 parts of glutinous rice, 20 parts of amylase, 10 parts of alkali, 2 parts of green water monoglyceride, 1 part of sucrose lipid, 10 parts of glucose oxidase, 10 parts of resistant starch , 17 parts of lecithin.

[0037] The preparation steps are as follows:

[0038] a. taking the above-mentioned raw materials according to parts by weight;

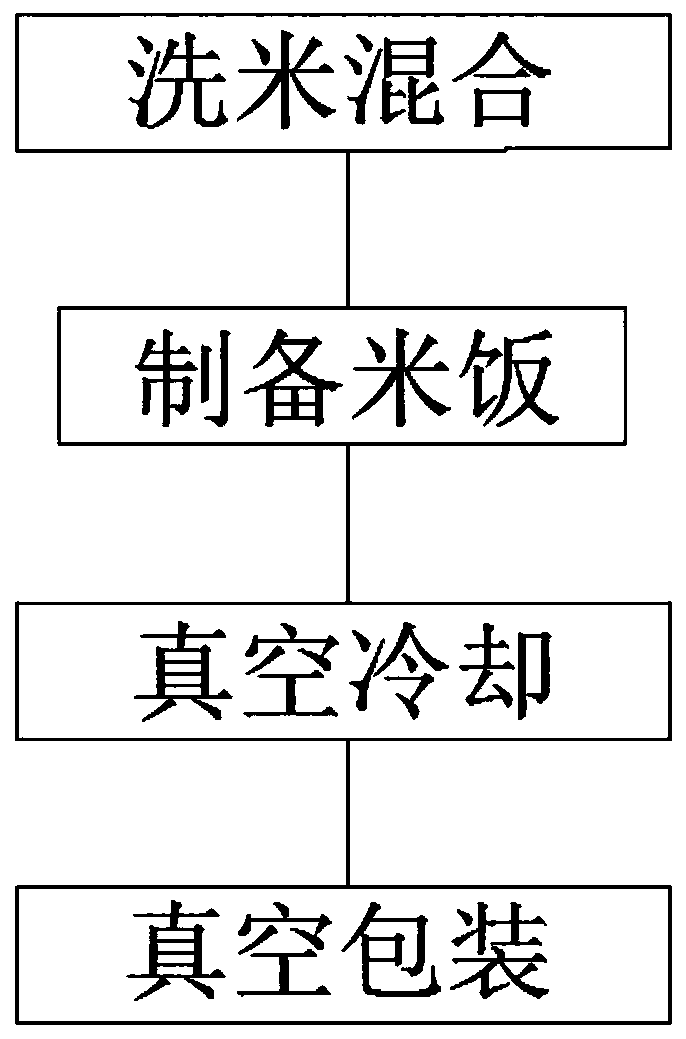

[0039] Step 1: first wash rice, soak rice, sell dry rice, then add water, amylase, alkali, green water monoglyceride, sucrose lipid, glucose oxidase, resistant starch and lecithin according to the proportion, and use the heating device to prepare semi-cooked rice;

[0040] Step 2: Add water and stir evenly, heat to prepare cooked rice, and after obtaining cooked rice, cool the rice with a vacuum machine;

[0041] Step 3: finally freeze and preserve at a temperature of -25°C to -10°C;

[0042] Step 4: Pack the refrigerated raw rice...

Embodiment 2

[0044] The anti-retrograde rice material includes the following raw materials and their weight fractions: 35 parts of glutinous rice, 23 parts of amylase, 14 parts of alkali, 3 parts of green water monoglyceride, 3 parts of sucrose lipid, 12 parts of glucose oxidase, 13 parts of resistant starch , 18 parts of lecithin.

[0045] The preparation steps are as follows:

[0046] a. taking the above-mentioned raw materials according to parts by weight;

[0047] Step 1: first wash rice, soak rice, sell dry rice, then add water, amylase, alkali, green water monoglyceride, sucrose lipid, glucose oxidase, resistant starch and lecithin according to the proportion, and use the heating device to prepare semi-cooked rice;

[0048] Step 2: Add water and stir evenly, heat to prepare cooked rice, and after obtaining cooked rice, cool the rice with a vacuum machine;

[0049] Step 3: finally freeze and preserve at a temperature of -25°C to -10°C;

[0050] Step 4: Pack the refrigerated raw ric...

Embodiment 3

[0052] The anti-retrograde rice material includes the following raw materials and their weight fractions: 40 parts of glutinous rice, 25 parts of amylase, 15 parts of alkali, 5 parts of green water monoglyceride, 5 parts of sucrose lipid, 15 parts of glucose oxidase, 15 parts of resistant starch , 20 parts of lecithin.

[0053] The preparation steps are as follows:

[0054] a. taking the above-mentioned raw materials according to parts by weight;

[0055]Step 1: first wash rice, soak rice, sell dry rice, then add water, amylase, alkali, green water monoglyceride, sucrose lipid, glucose oxidase, resistant starch and lecithin according to the proportion, and use the heating device to prepare semi-cooked rice;

[0056] Step 2: Add water and stir evenly, heat to prepare cooked rice, and after obtaining cooked rice, cool the rice with a vacuum machine;

[0057] Step 3: finally freeze and preserve at a temperature of -25°C to -10°C;

[0058] Step 4: Pack the refrigerated raw rice...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap