Bare concrete prefabricated block and ganged brick composite outer wall and assembling and building method thereof

A technology of fair-faced concrete and prefabricated blocks, which is applied to walls, building materials, and building components. It can solve the problems of long construction period, poor protection of finished products, and high cost of formwork, and achieve the effects of easy use, improved integrity, and excellent economic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

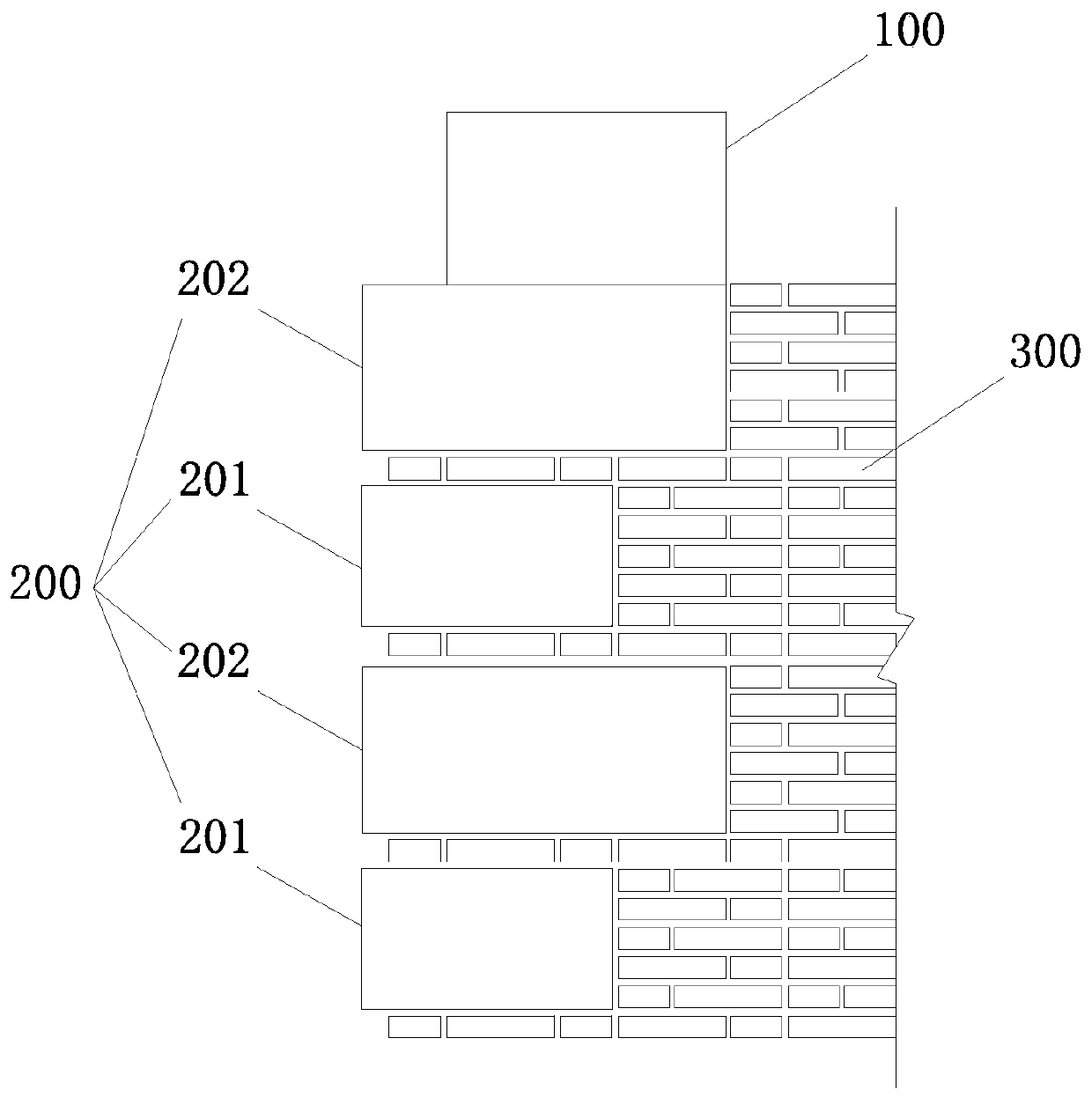

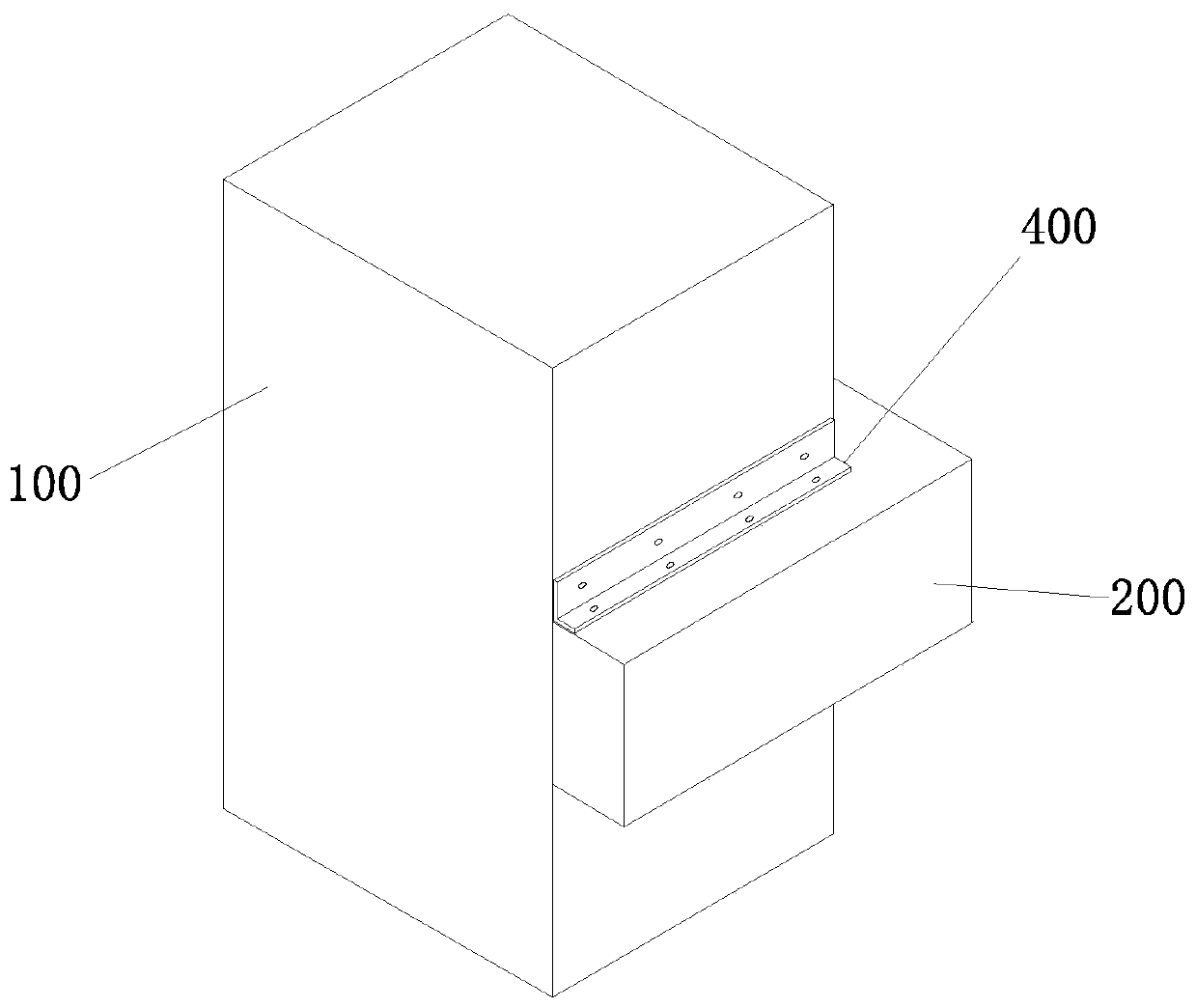

[0030] combine Figure 1 to Figure 3 As shown, the composite exterior wall of prefabricated concrete blocks and bricks provided in this embodiment mainly relates to the corner structure of the composite exterior wall. The corner of the composite exterior wall is provided with a structural column 100; the fair-faced concrete prefabricated block 200 is an L-shaped structure, and is horizontally arranged on the structural column 100 at the corner of the composite exterior wall through an L-shaped angle iron connector 400; At least one skin of clear water bricks 300 is arranged between two adjacent clear water concrete precast blocks 200, and several layers of clear water bricks 300 are horizontally arranged at both ends of the clear water concrete precast blocks 200.

[0031] Further, the outer surface of the clear water brick 300 is lower than the outer surface of the fair faced concrete prefabricated block 200, so that the outer surface of the fair faced concrete precast block ...

Embodiment 2

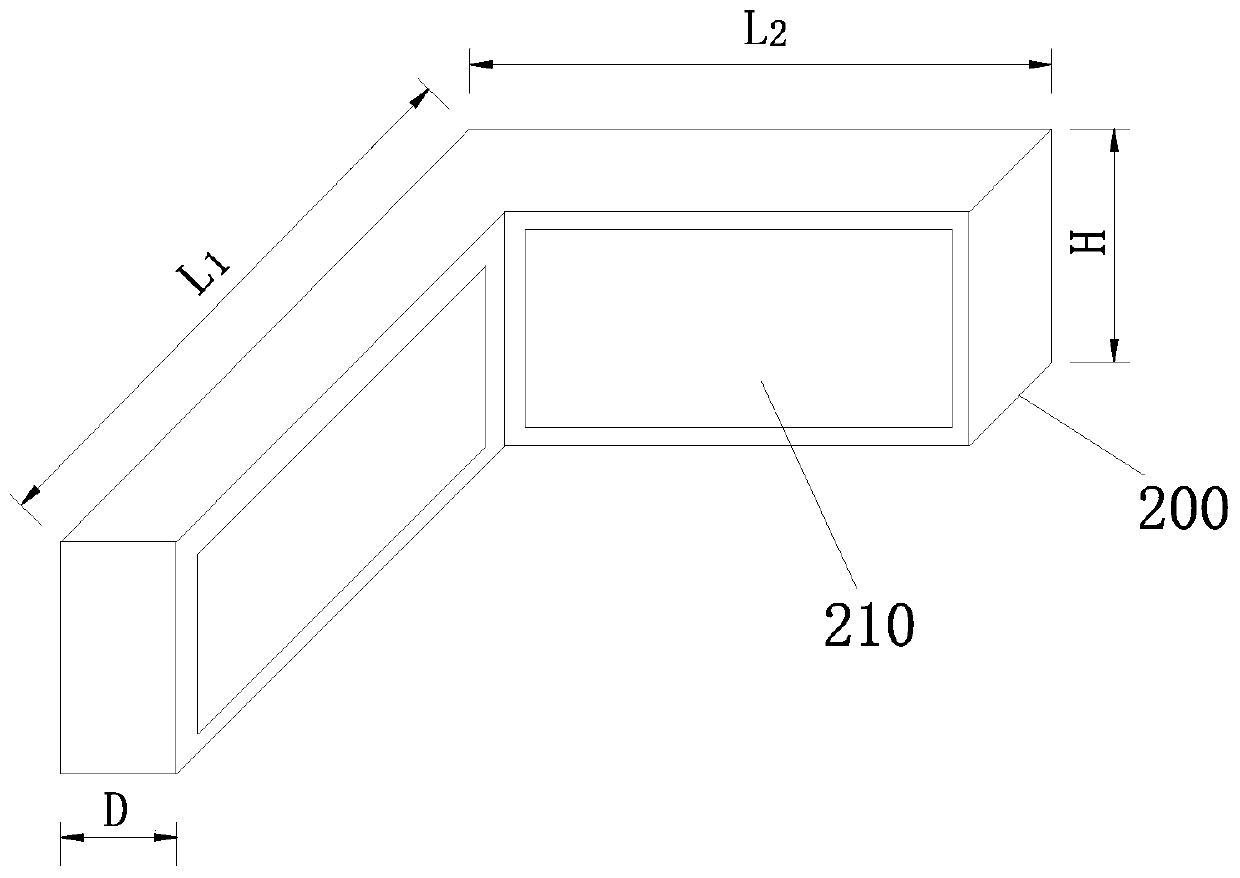

[0036] The construction method of a kind of clear-faced concrete prefabricated block and clear-faced brick composite exterior wall that present embodiment provides, combine below Figure 1 to Figure 3 As shown, the construction method is further described. Described clear-faced brick 300 adopts long 210mm, wide 115mm, the sintered shale hollow brick of high 53mm; Clear-water concrete prefabricated block 200 comprises that prefabricated block one 201 and prefabricated block two 202 are arranged at intervals successively; The size of described prefabricated block one 201 is as follows: L 1 , L 2 Both are 610mm, the height H is 313mm, and the thickness D is 180mm; the size of the prefabricated block 2 202 is as follows: L 1 , L 2 Both are 925mm, the width H is 378mm, and the thickness D is 180mm. Described construction method comprises the steps:

[0037] Step 1. Build a layer of clear water brick 300 at the bottom of the corner structural column 100 of the composite exterior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com