Makeup system special for manufacturing wide-surface laser holographic mother set

A laser holography and mastering technology, which is applied in the field of ultra-fine processing and laser holography, can solve the problems of expansion deformation, uneven heating, and lower qualified rate of finished products, and achieve the effect of reducing thermal deformation and lowering surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

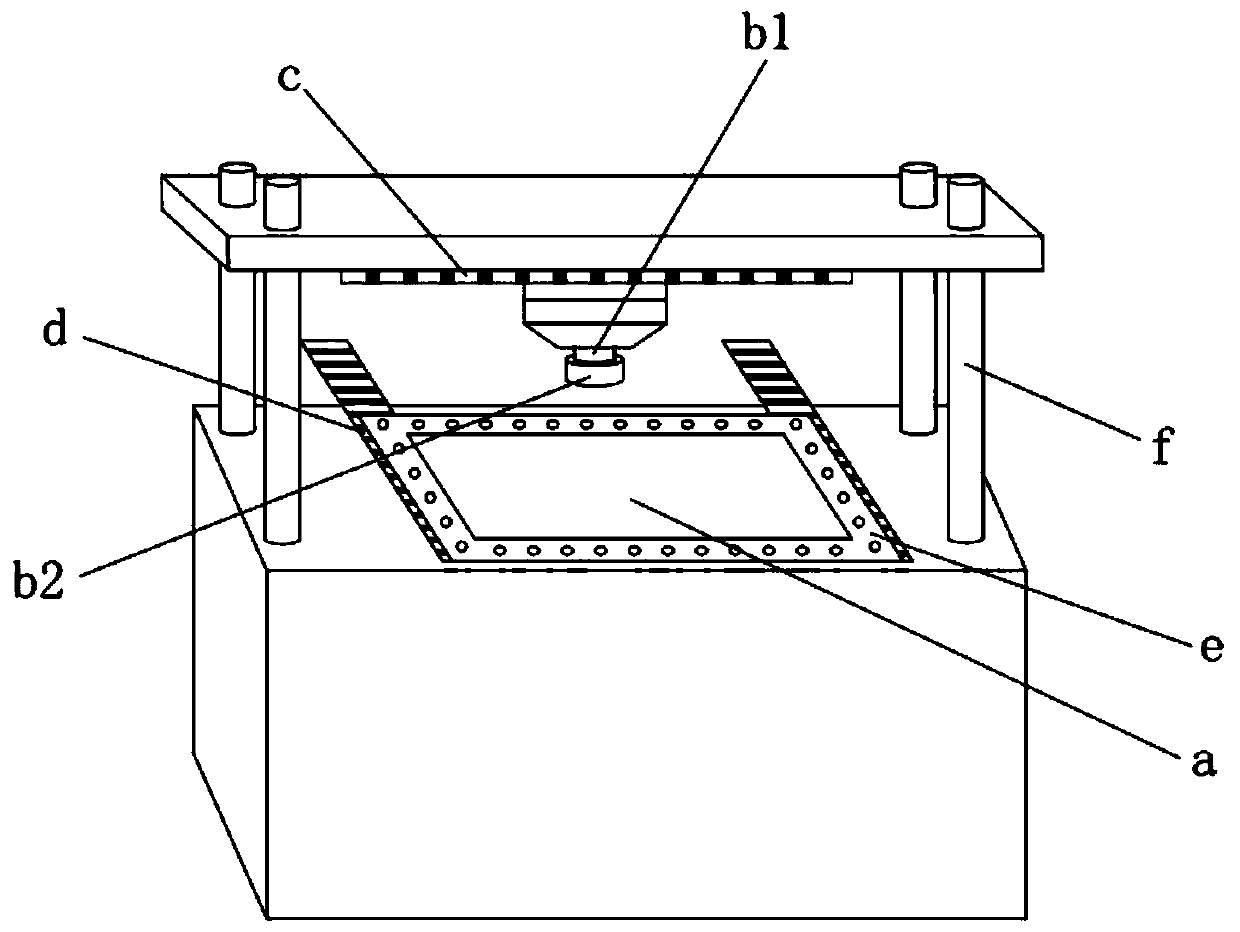

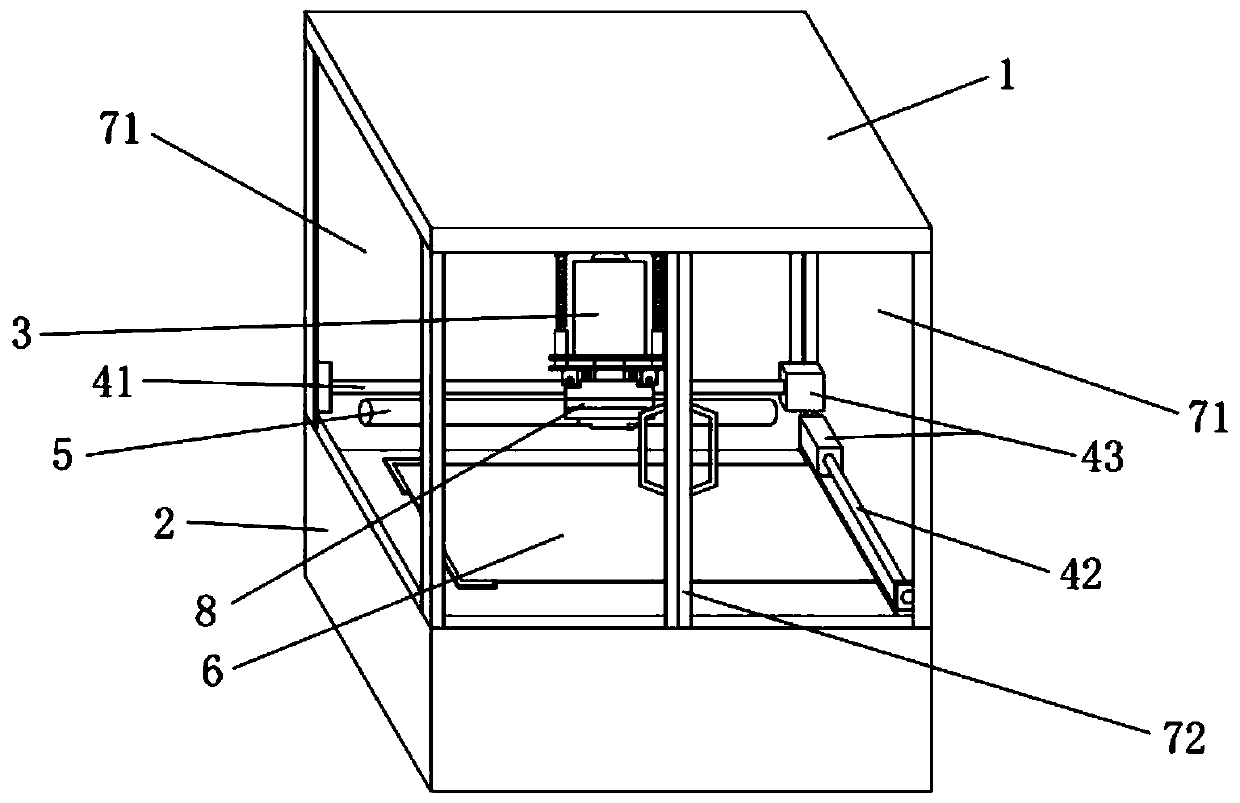

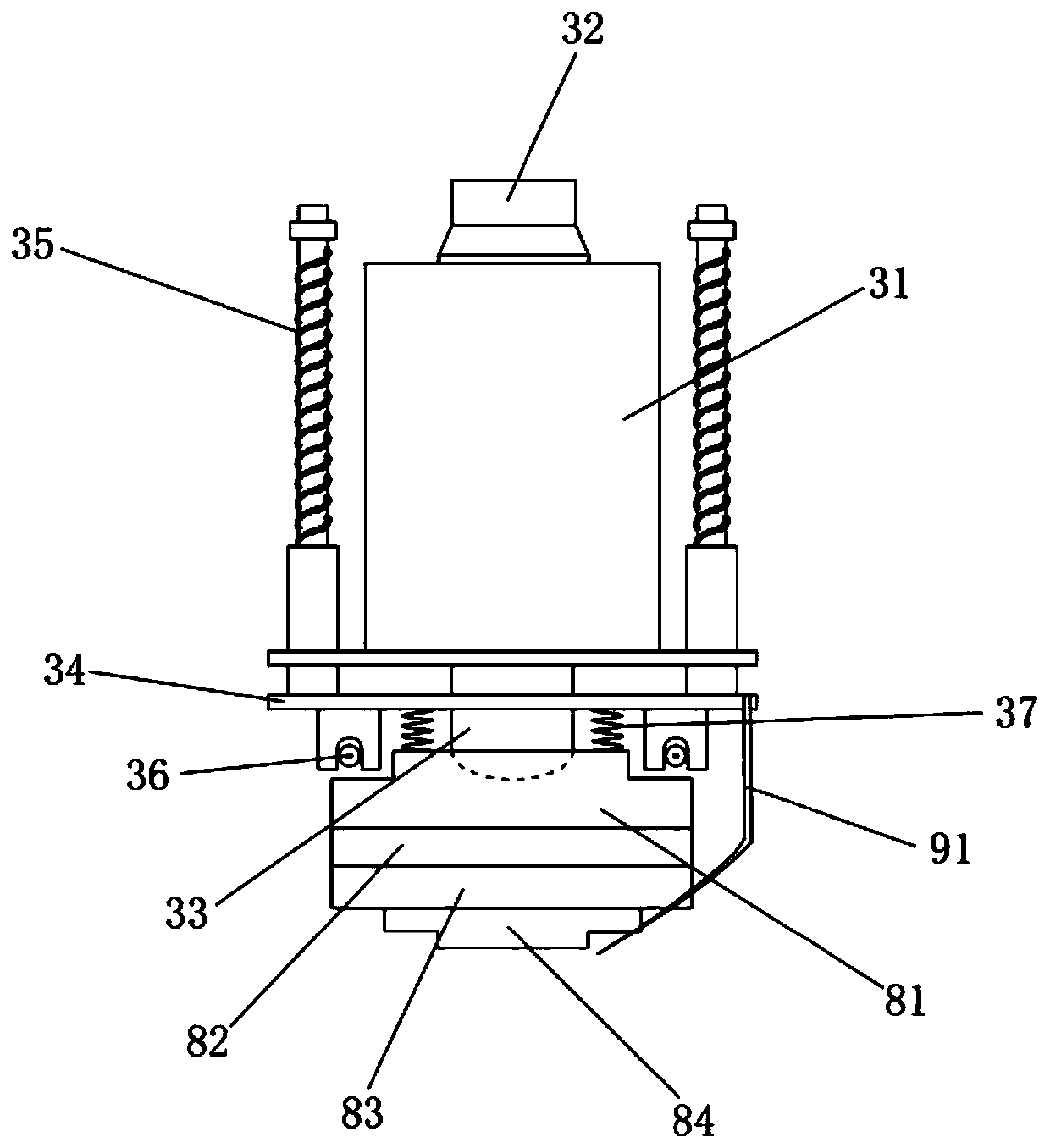

Image

Examples

Embodiment 1

[0042] Embodiment one is a preferred version of the present invention, and the following is an example to illustrate the process of the work of the present invention with Embodiment two:

[0043] Step 1: Turn on the main power switch 105, prepare a unit holographic image working plate with a moderate thickness, cut a suitable working plate with a cutting machine according to the imposition head 84 prepared in advance, and use the positioning groove to level it Paste on the imposition head 84, and then load the imposition head 84 onto the lower end of the heating plate 83; set an appropriate temperature through the temperature setting on the main control system and the display screen 106, and the heating plate 83 starts heating.

[0044] Step 2: Take a test piece of imposition base material and fix it on the lower steel platform 2. The imposition application program in the computer in the main control system moves the mobile platform to the top of the test piece along the ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com