High-power high-voltage direct-current contactor

A high-voltage DC, contactor technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of insufficient arc extinguishing effect, low magnetic field strength, unreasonable distribution of magnetic steel, etc., to reduce heat and burn effects , reduce safety hazards and improve the effect of arc extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

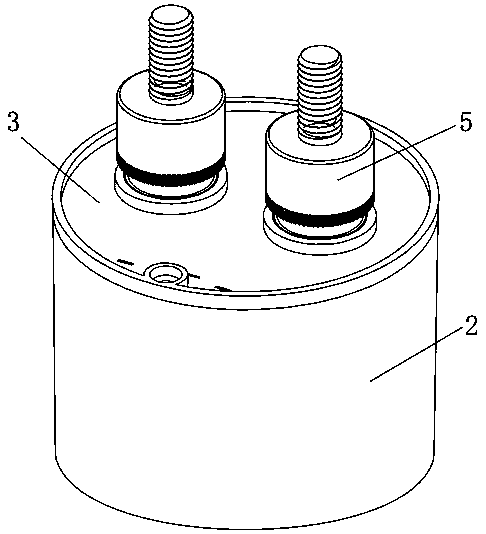

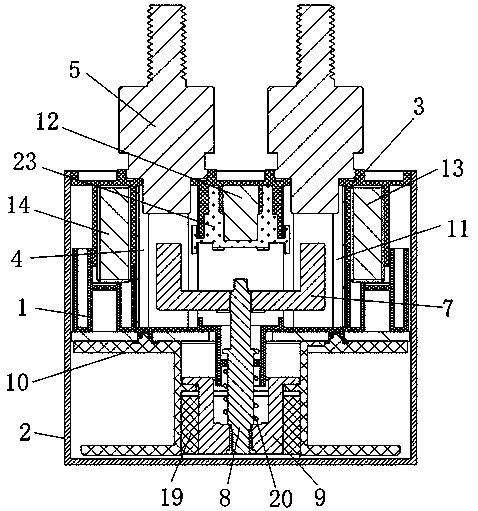

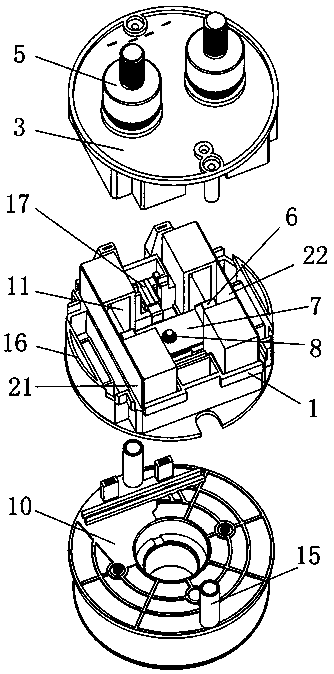

[0026] Embodiment one, such as Figure 1 to Figure 5 As shown, a high-power high-voltage DC contactor includes a base 1, a housing 2 and an arc extinguishing cover 3. The arc extinguishing cover 3 is clamped on the base 1, and the base 1 and the arc extinguishing cover 3 form an arc extinguishing chamber 4. , the arc extinguishing chamber 4 is provided with a fixed contact 5 and a moving contact 6, the fixed contact 5 is fixedly installed on the arc extinguishing cover 3, the cross section of the moving contact 6 is an equilateral trapezoid, the small end of the moving contact 6 is in line with the The positions of the fixed contacts 5 are opposite, the large end of the moving contact 6 is fixedly installed on the moving iron 7, and the moving iron 7 is fixedly connected to the first connecting column 8, and the end of the first connecting column 8 is connected to the moving iron core. 9 is fixedly connected, the moving iron core 9 is rotatably installed in the inner cavity of...

Embodiment 2

[0030] Embodiment 2, this embodiment is a preferred technical solution of Embodiment 1. A reinforced connecting rod 15 is provided on the take-up frame 10, and the reinforced connecting rod 15 and the arc extinguishing cover 3 are engaged with each other, and the base 1 is fixedly connected with a Buckle 16, and the buckle 16 is engaged with the arc extinguishing cover 3 . The reinforced connecting rod 15 and the arc extinguishing cover 3 are engaged with each other, and the buckle 16 clamps the arc extinguishing cover 3 on the base 1, which can prevent the temperature in the arc extinguishing cover 3 from rising rapidly, and the arc extinguishing cover 3 is blasted or directly rushed away .

Embodiment 3

[0031] Embodiment 3, this embodiment is a preferred technical solution of Embodiment 1, a contact block 17 is fixedly installed on the moving contact iron 7, and a switch 18 corresponding to the contact block 17 is fixedly installed on the top wall of the arc extinguishing cover 3 , the contactor is provided with a synchronous switch 18, when the moving contact iron 7 moves up, the moving contact 6 contacts the static contact 5, and at the same time the contact block 17 moves up together until it contacts the switch contact of the switch 18, the switch 18 is closed, The contactor circuit is connected; when the moving contact 6 is separated from the static contact 5, the contact block 17 is not in contact with the switch 18, and the contactor circuit is disconnected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com