Pen clip base positioning and assembling device and method

An assembly device and pen holder technology, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of material waste during maintenance, deviation of the direction and angle of the pen holder, angle difference, etc., to reduce personnel maintenance costs , avoid assembly damage, and reduce the effect of small pauses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0032] The pen holder positioning and assembling device disclosed by the present invention can accurately assemble the pen holder to the pen clip, avoiding damage to the pen holder and the pen clip.

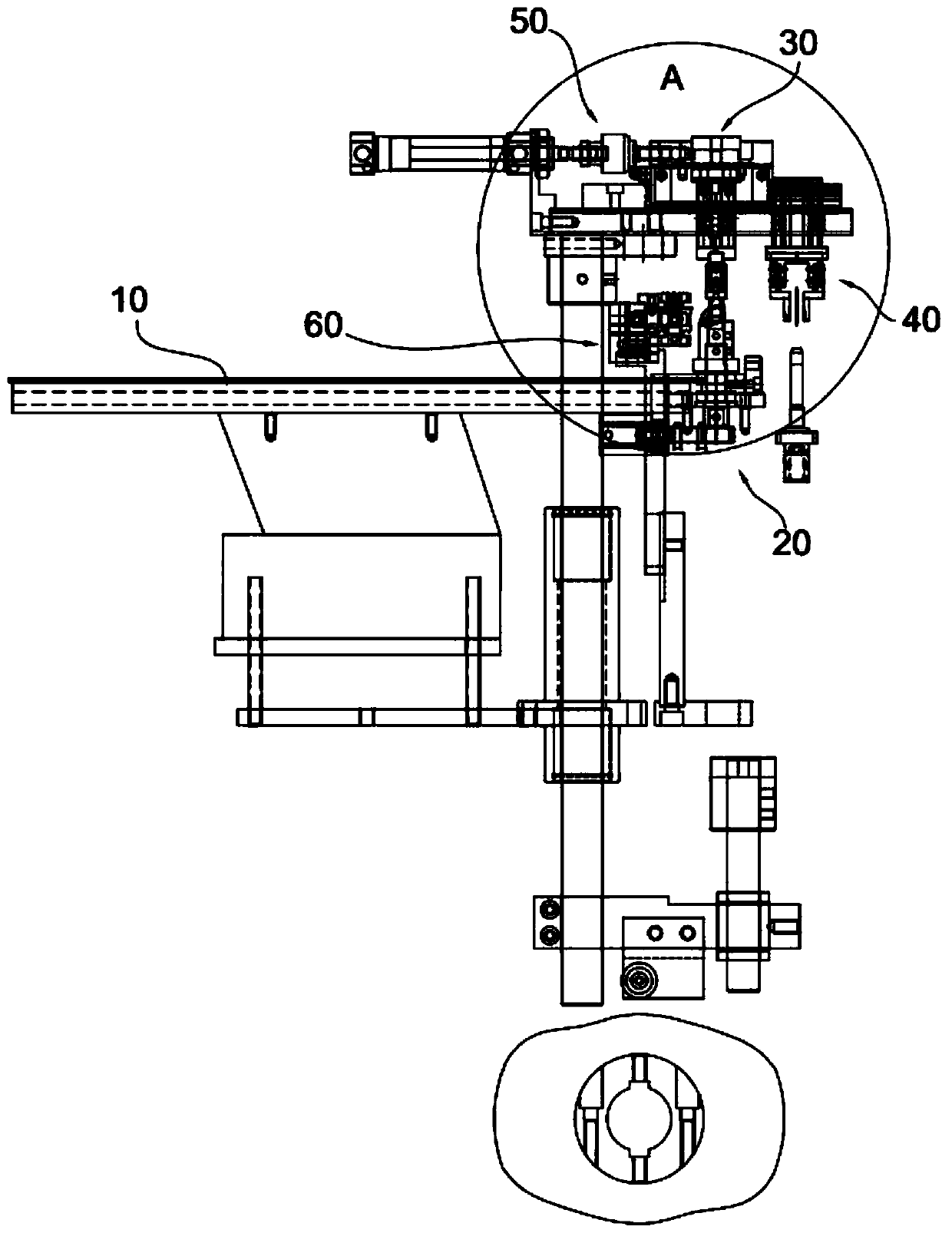

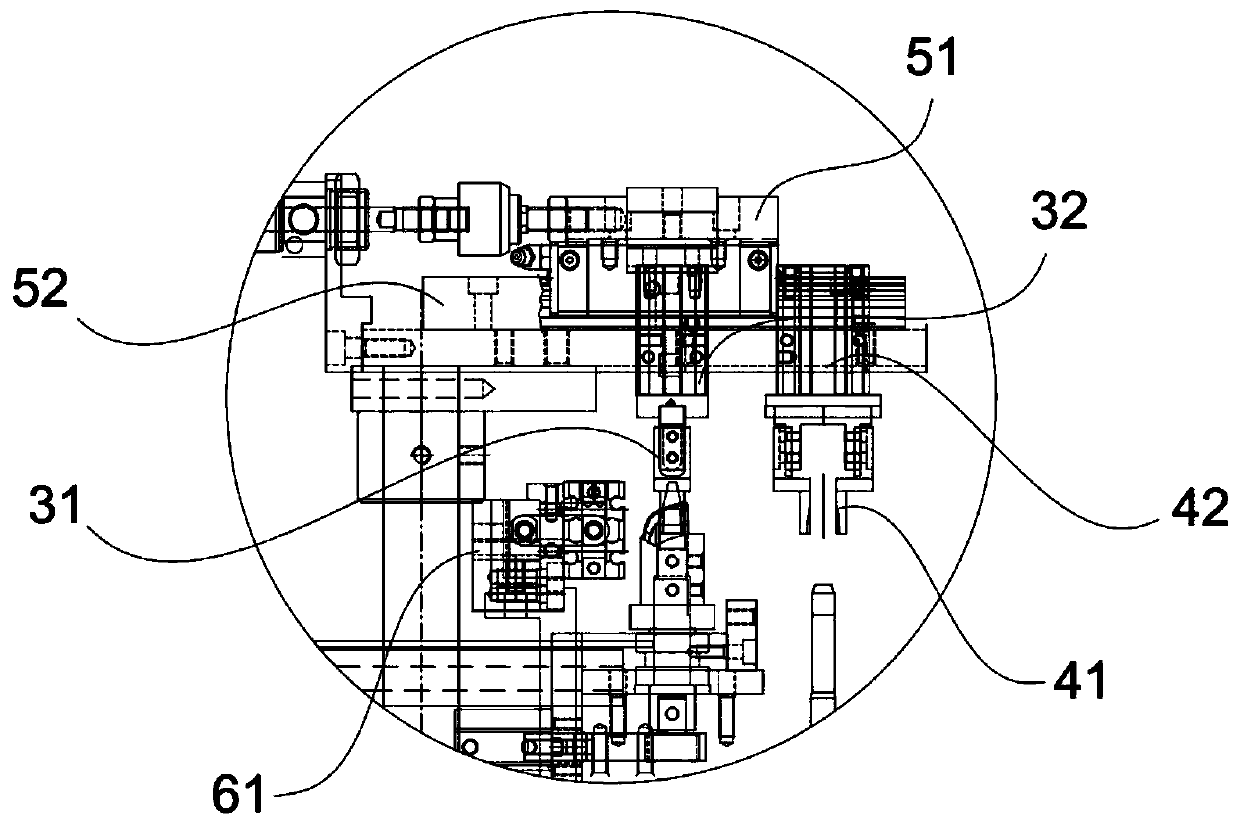

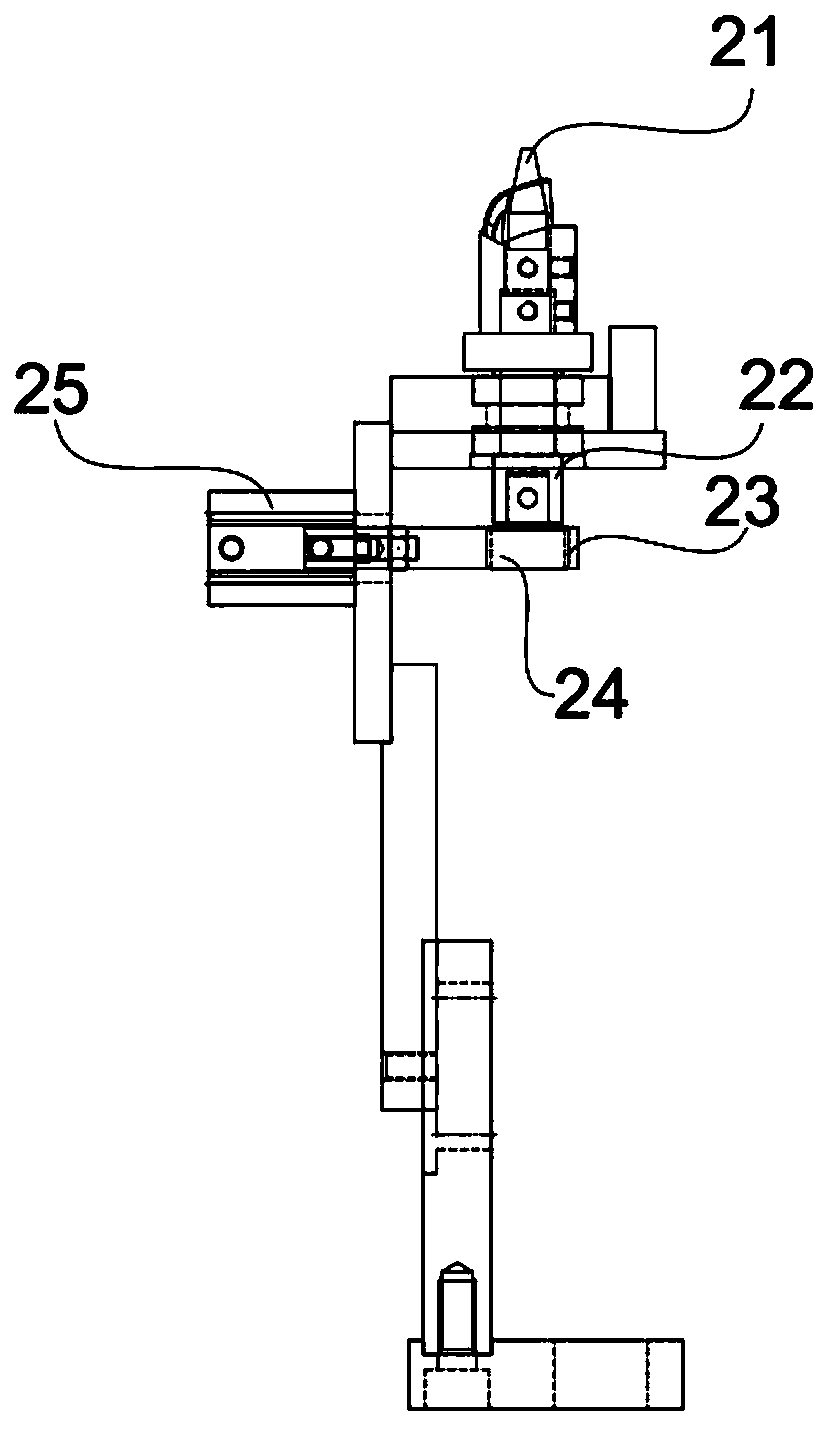

[0033] combine Figure 1 ~ Figure 3 As shown, it is a pen holder positioning assembly device disclosed by the present invention, which includes a vibrating plate, at least one pen holder positioning and rotating mechanism 20, a pen holder clamping mechanism 30 and a pen holder assembly mechanism 40, wherein the vibration The disc is used to make the clamping portion of the pen holder move towards the preset moving direction of the pen holder and transport the pen holder outward; The pen holder rotates at a preset angle to ensure that the angle of the pen holder and the clamping part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com