Improved Servo Control Oil Supply Device

A servo control and oil supply device technology, applied in liquid fuel engines, mechanical equipment, pumps, etc., can solve problems affecting the lubrication and heat dissipation of spline drive shafts, poor circulation, and temperature rise of pump bodies, so as to solve mechanical damage Problems, prolonging the service life, and ensuring the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

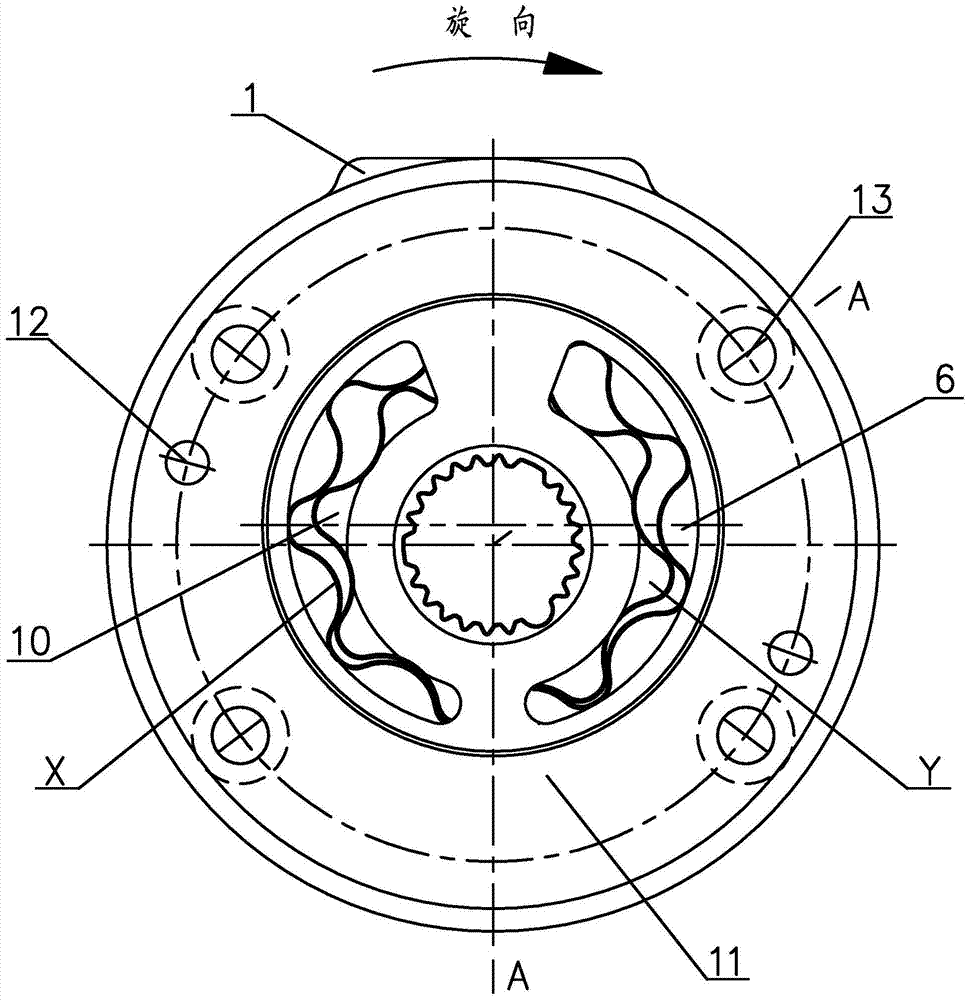

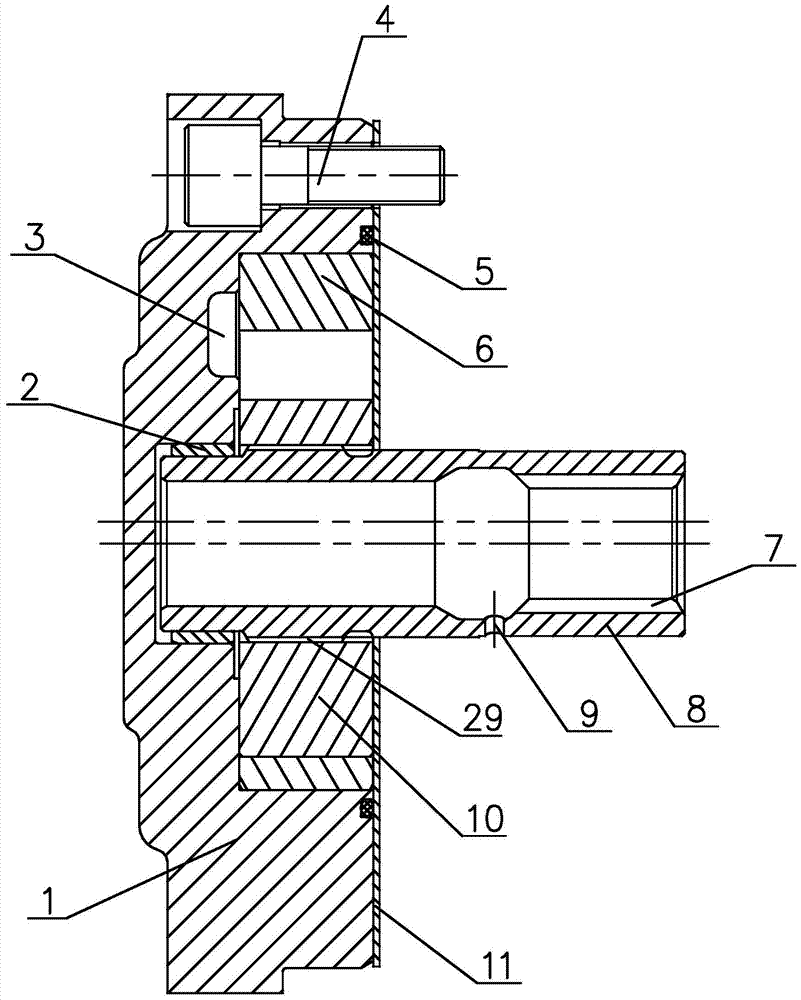

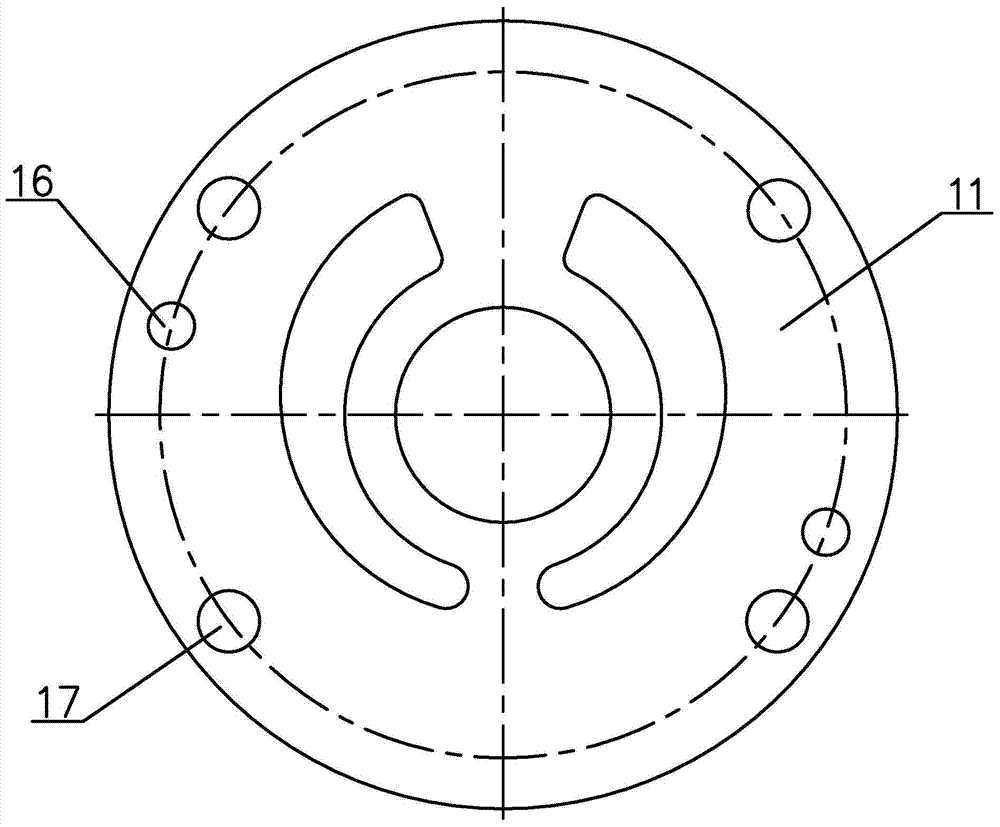

[0029] see Figure 1-10 The improved servo control oil supply device includes pump body 1, bearing body 2, oil chamber 3, fastening screw 4, O-ring 5, cycloid outer rotor 6, transmission inner spline 7, spline drive shaft 8 , oil hole 9, cycloid inner rotor 10, side plate 11, pump body positioning hole 12, pump body fastening hole 13, assembly process groove 14, pump cavity sealing end face 15, side plate positioning hole 16, side plate fastening Hole 17, inner rotor positioning arc 18, inner rotor left positioning groove 19, inner rotor right positioning groove 20, pin body 21, deformation filling groove 22, contraction positioning slope 23, left oil storage tank 24, right oil storage tank 25. Assembly contraction port 26, sliding anti-wear la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com