Pump body structure, compressor and air conditioner

A compressor and pump body technology, applied in the field of compressors, can solve problems such as poor volumetric efficiency of the pump body, reduced air intake, and reduced energy efficiency of the compressor, achieving the effects of reducing heating, improving energy efficiency, and ensuring volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

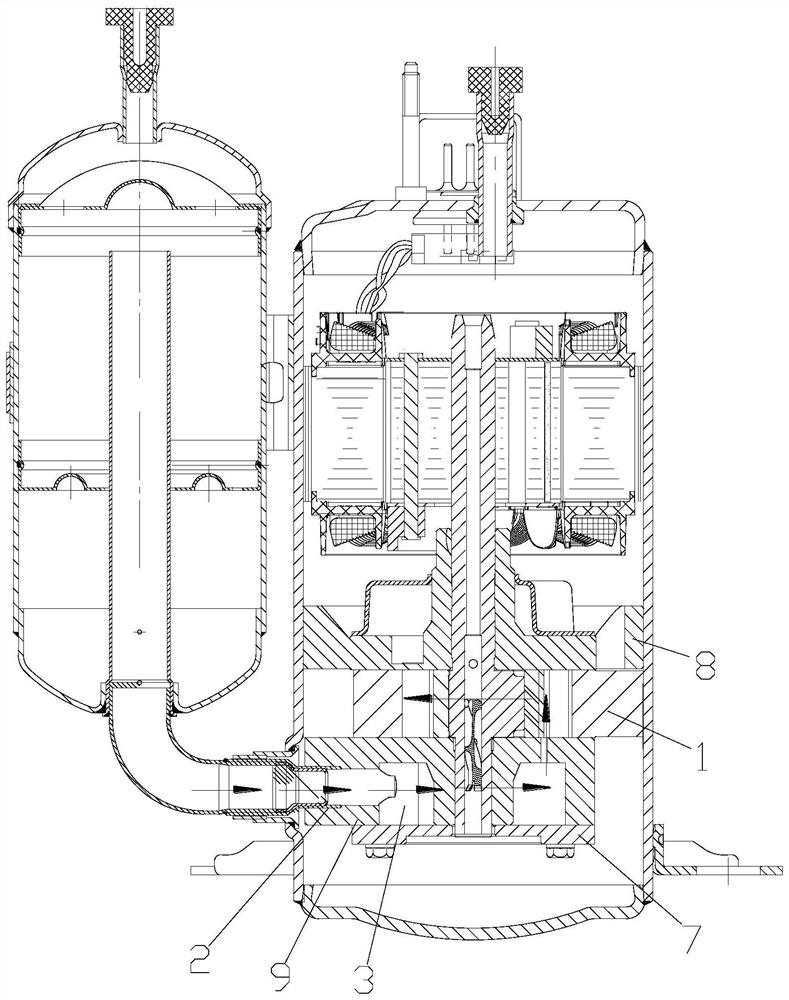

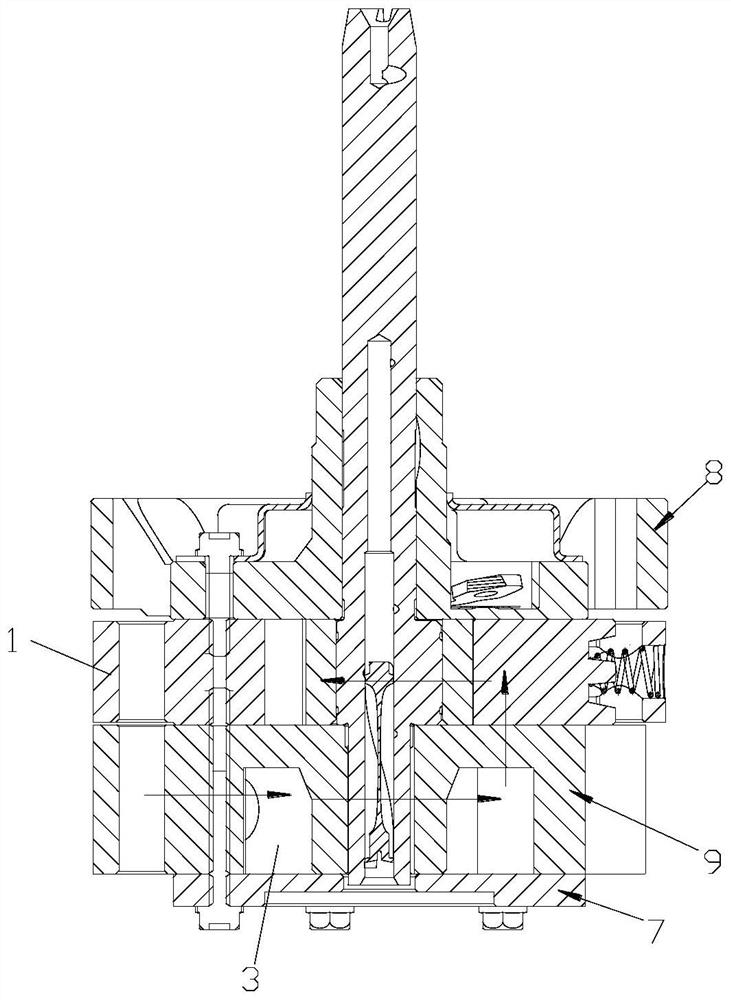

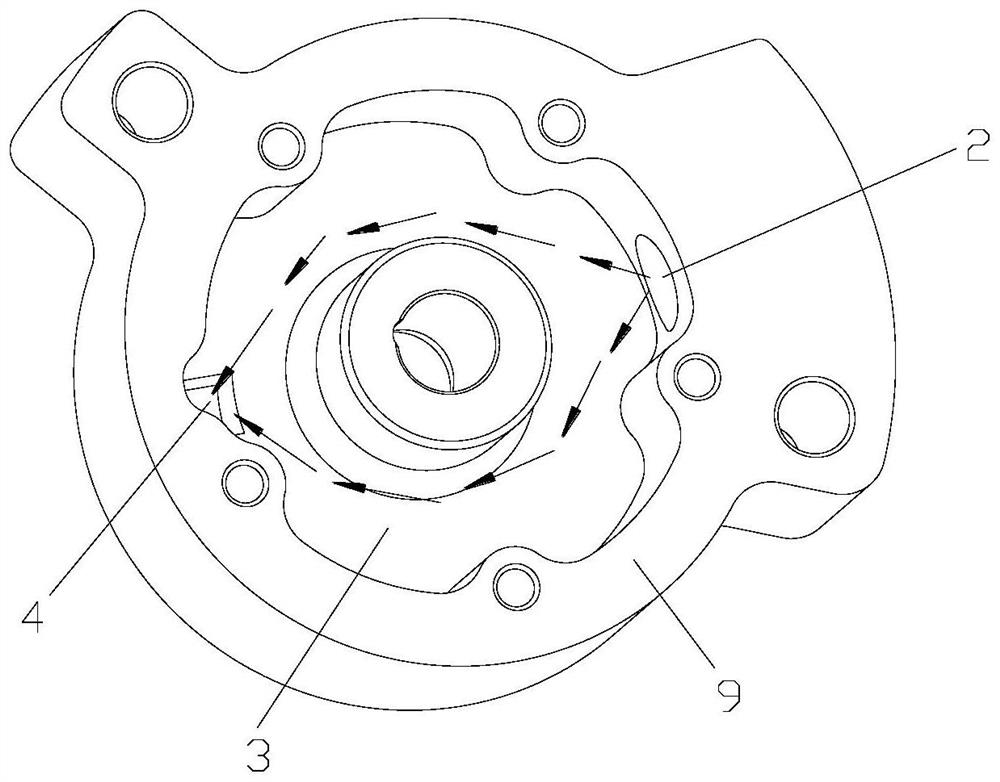

[0024] In the related technology, the low-temperature and low-pressure refrigerant from the refrigeration system directly enters the suction low-pressure cavity through the suction hole on the cylinder, because the gas is directly sucked into the cylinder, the refrigerant is easily heated during the suction process, and the gas will cause The volume of the gas becomes larger, so when the gas is sucked into the suction chamber, the temperature, pressure and volume of the refrigerant will be higher than expected, which will lead to a decrease in the suction capacity of the compressor during operation, a decrease in volumetric efficiency, and indirectly lead to compression Reduced performance.

[0025] To solve this problem, see Figure 1 to Figure 5 As shown, according to the embodiment of the application, the pump body structure includes a cylinder 1 and a flange, the flange has a suction hole 2 and a sealing cavity 3, the cylinder 1 has a suction chamber and a compression cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com