Modified PVDF (Polyvinylidene Fluoride) material, and preparation method and application thereof

A modification and raw material technology, which is applied in the field of material preparation and application, can solve the problems of poor precision of finished products, high cost and high shrinkage of PVDF materials, etc., to reduce shrinkage, reduce material costs, improve processability and mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

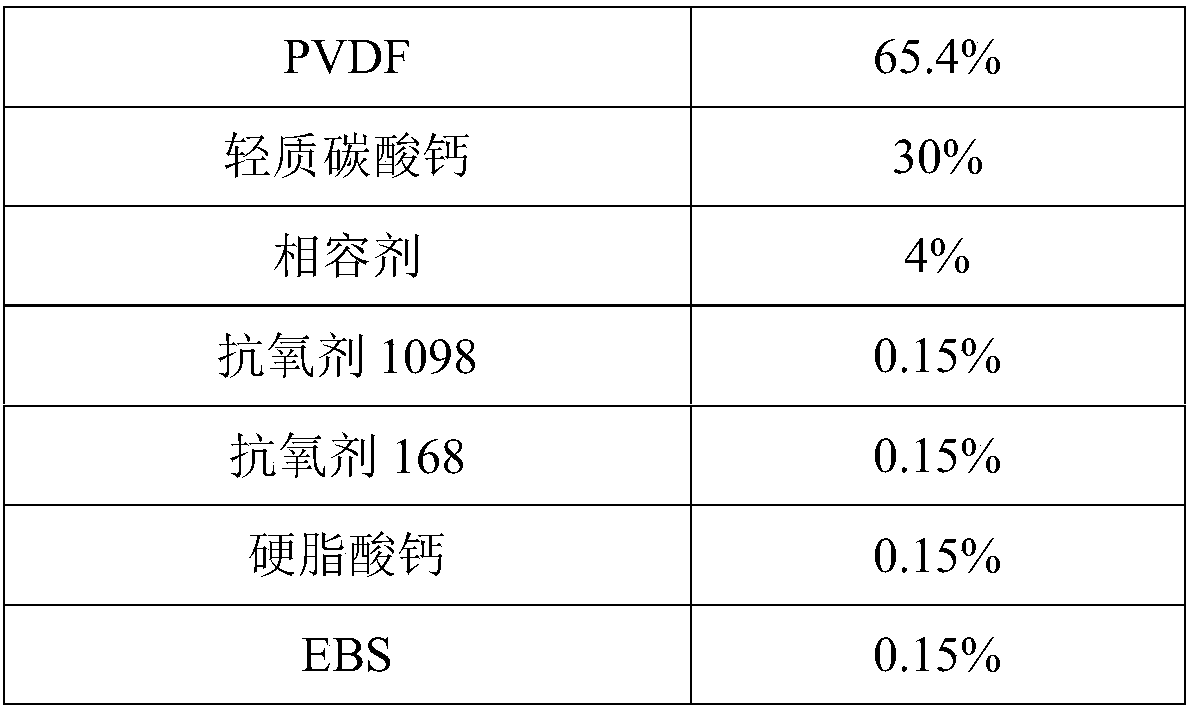

[0036]Polyvinylidene fluoride (abbreviated as PVDF) is a resin with a large shrinkage rate. PVDF has better fluidity, but the shrinkage varies from 2.5% to 2.8% in different molds and process conditions. Therefore, when designing the mold, it is important to accurately determine the shrinkage rate of the product in all directions, but for products with strict size requirements such as the pump head of the metering pump, it is also necessary to adjust the shrinkage rate of PVDF resin through modification. It is necessary to modify PVDF to reduce shrinkage and reduce material cost through blending modification. The modification mainly includes adding inorganic mineral powder for melt blending and granulation.

[0037] 1. Main raw materials

[0038] nam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com