Double-stator swing hydraulic multi-speed motor

A technology with double stators and motors, which is applied in the direction of swinging piston engines, rotating or swinging piston engines, machines/engines, etc., and can solve problems such as limiting the scope of application of swinging hydraulic motors, not being able to realize differential connections, and not being easy to change speed and torque. , to achieve the effect of light weight, stable work and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

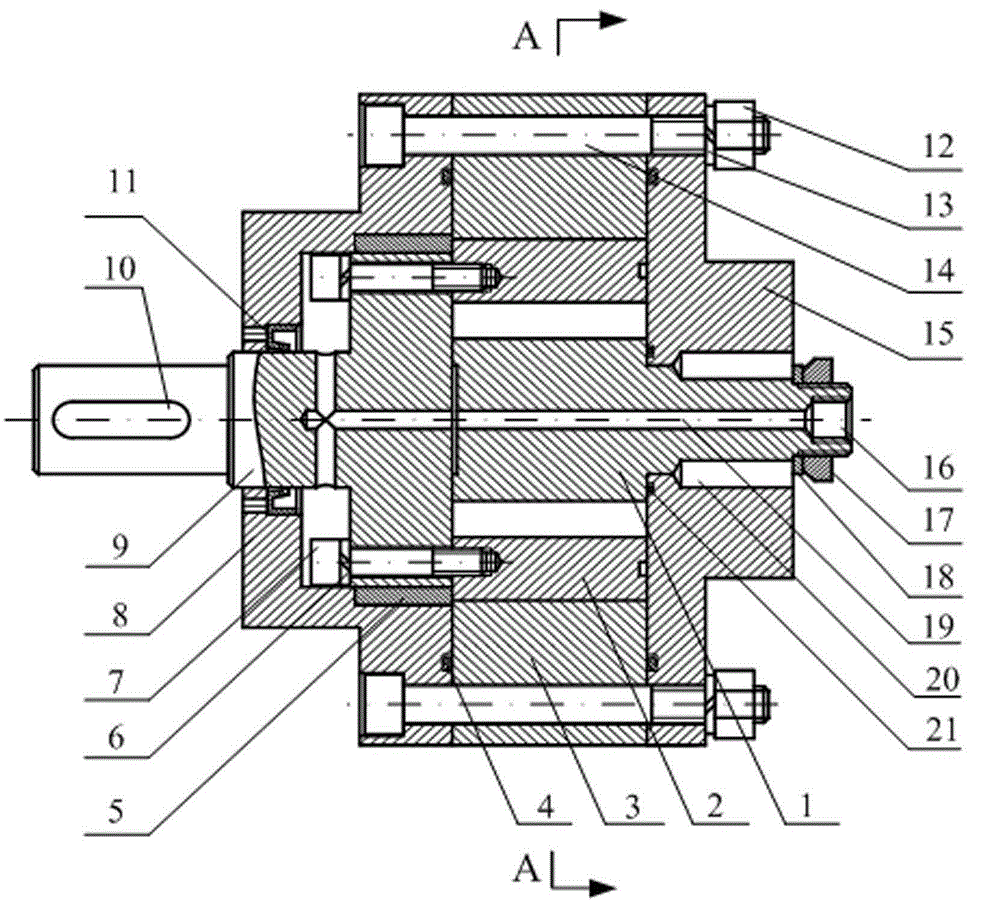

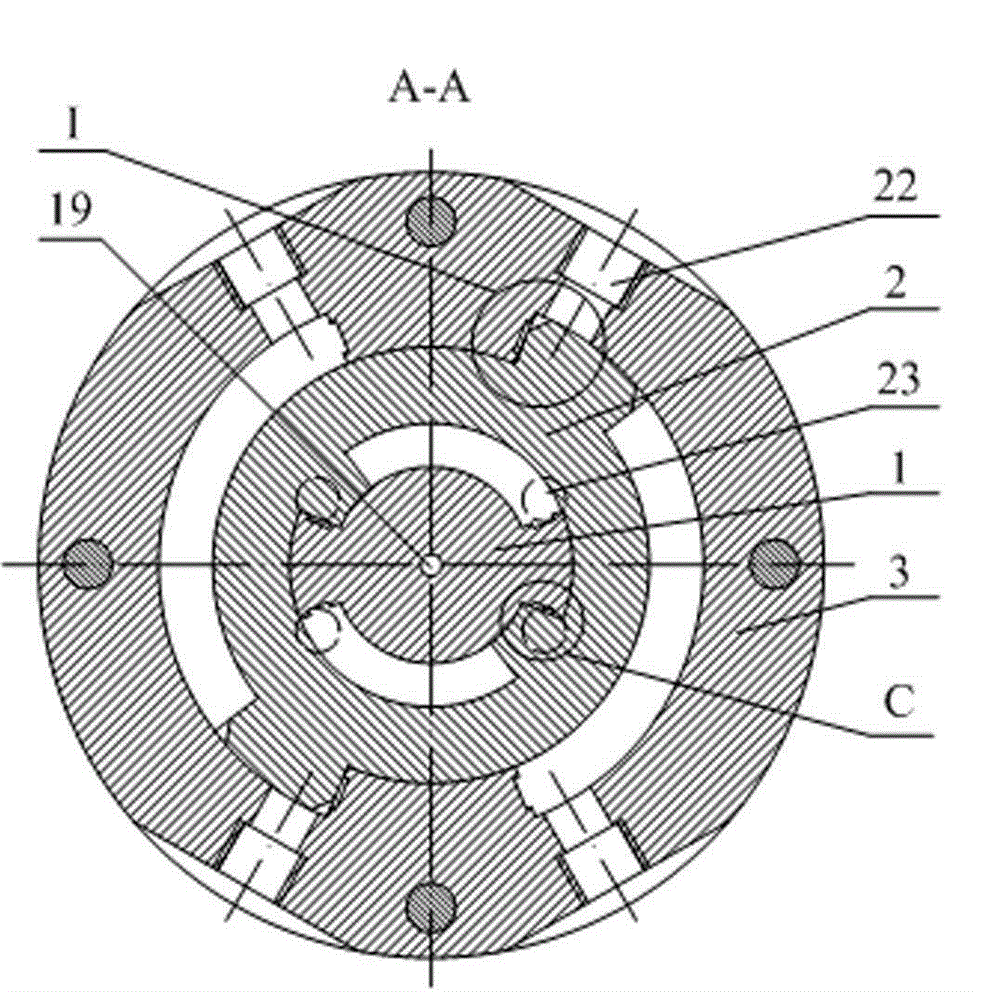

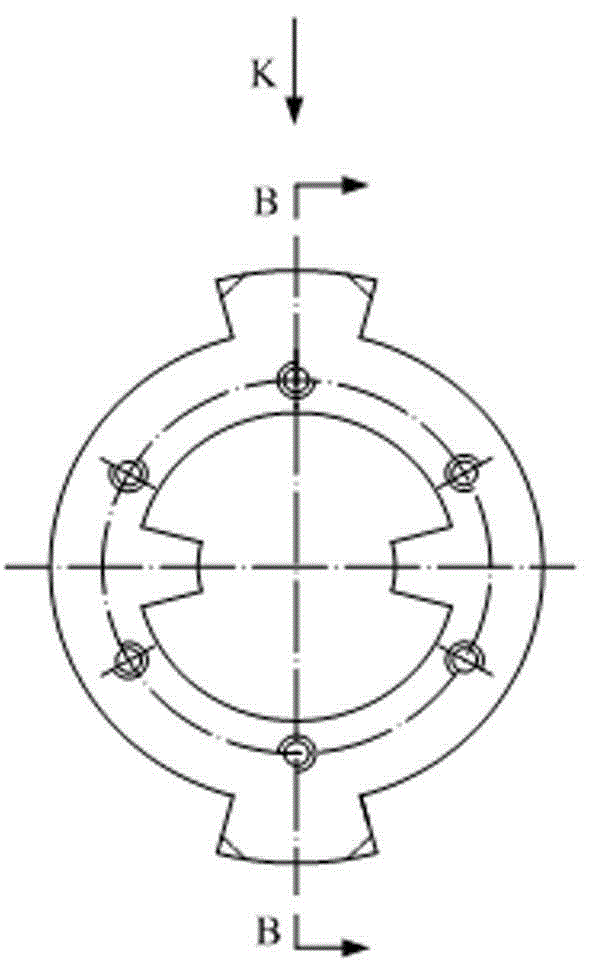

[0025] The invention discloses a double-stator swing hydraulic multi-speed motor (see figure 1 , figure 2 , image 3 ), including O-ring Ⅰ4, sliding bearing 5, O-ring Ⅱ21, left end cover 8, right end cover 15 and output shaft 9. The inner and outer surfaces of the annular rotor 2 of the double-stator swing hydraulic multi-speed motor are respectively provided with two raised inner and outer motor fan-shaped moving blades (33, 31), and the outer surface of the inner stator 1 is provided with two raised Inner motor fan-shaped stator blades 32, two protruding outer motor fan-shaped stator blades 30 are arranged on the inner surface of the outer stator 3, the inner stator 1 is installed in the ring rotor 2, the ring rotor 2 is installed in the cavity of the outer stator 3, the outer stator There are two outer motor oil distribution windows 22 on both sides of the outer motor fan-shaped fixed vane 30 of 3, and two inner motor oil distribution windows are opened on the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com