Strip assembly and production method

A technology of strips and components, applied in the direction of vehicle components, transportation and packaging, engine components, etc., can solve problems such as high risk of injury, cutting into workers' skin, deformation of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

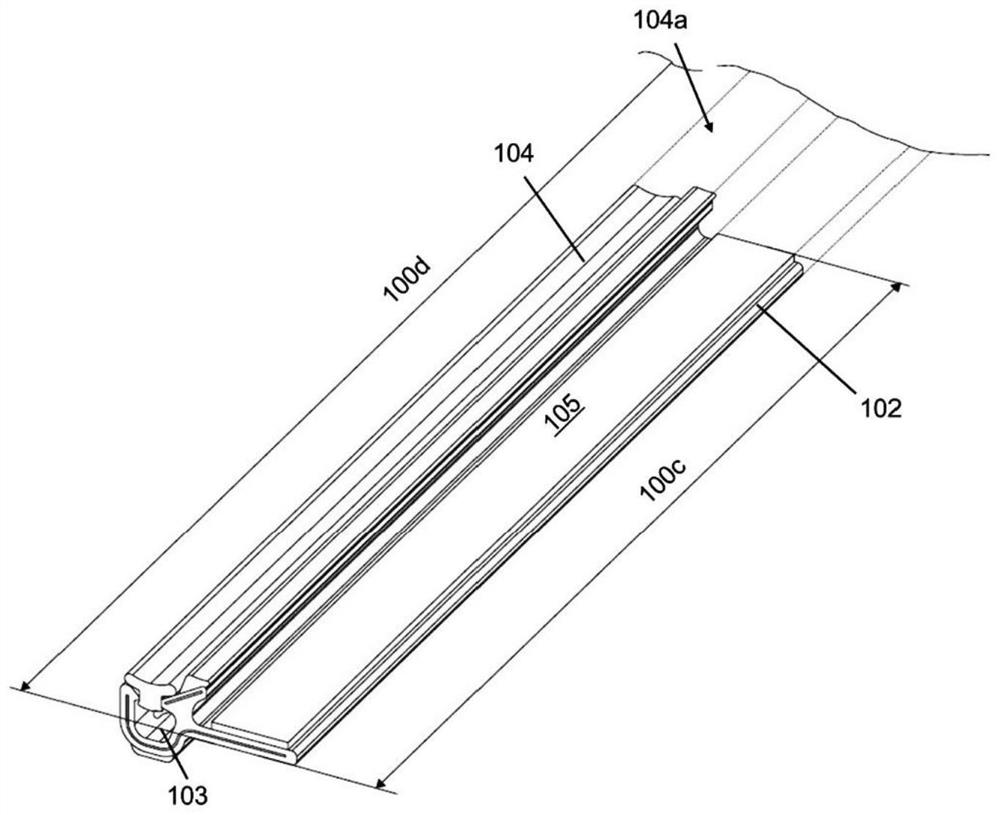

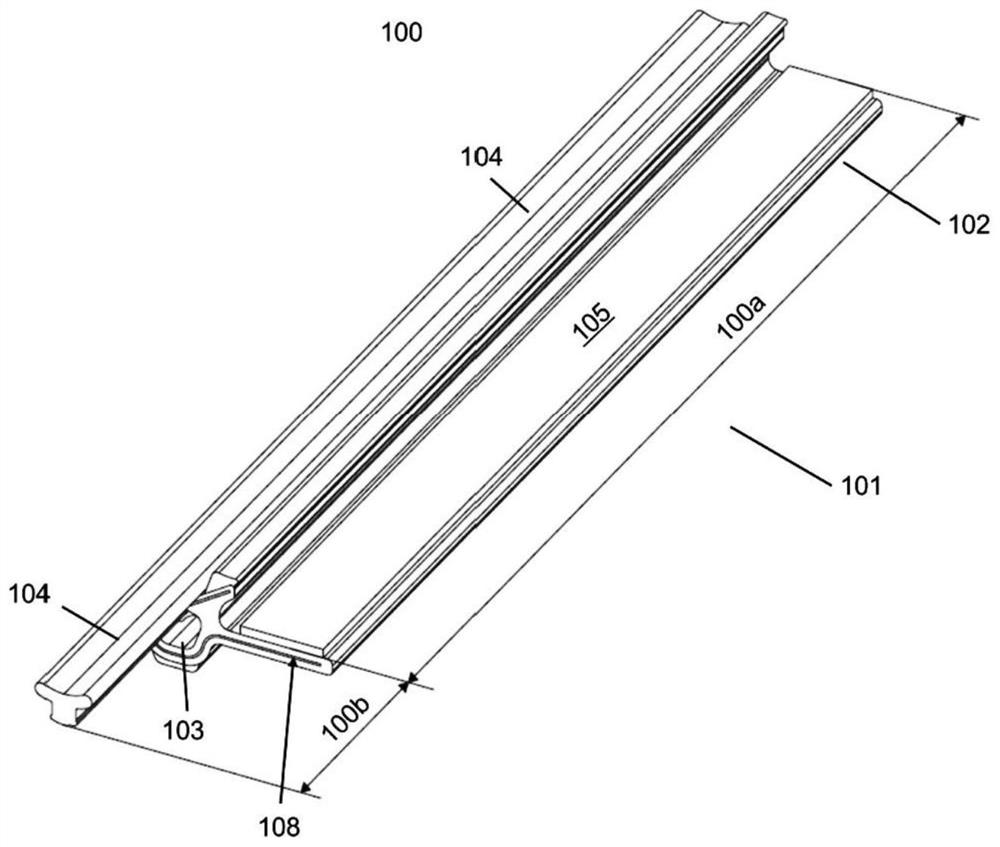

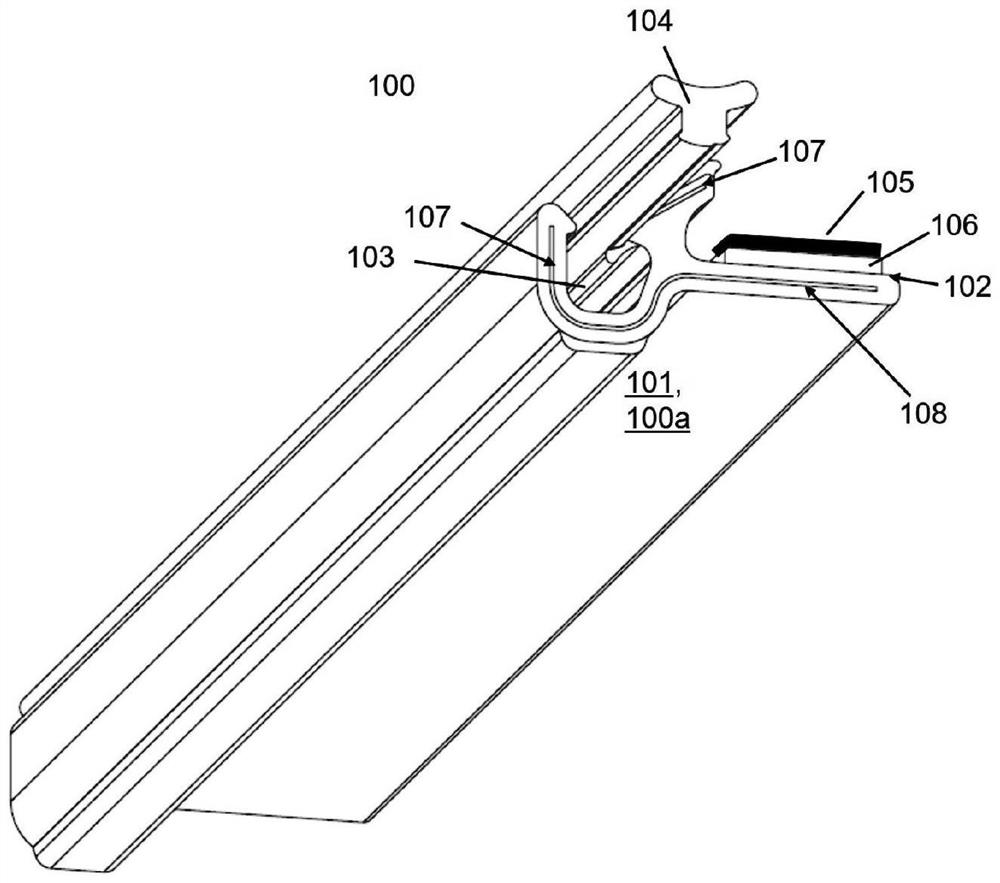

[0045] figure 1 Shown is a one-piece shaped strip strand 100d manufactured from at least one plastic material by extrusion and / or 3D printing processes. The profiled strap strand 100d includes a preferably continuous joint face 102 and locking groove 103 . A protective strip strand 104 a configured to correspond to the lock groove 103 is positively and / or frictionally inserted into the lock groove 103 . The protective strip strand 104a is also made in one piece from plastic material, preferably by extrusion or 3D printing. Double-sided tape (not visible) is bonded to the joint surface 102 . The second adhesive side of the double-sided tape, that is, the side that is not adhered to the joint surface 102 , is covered with a protective film 105 . The end segments of the profiled strap strand 100d and the protective strap strand 104a form a strap segment 100c which forms the base of the strap assembly 100 . The strands may be severed from the forming strap strand 100d and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com