ISG electrical machine mounting jig of the engine

A technology for installing fixtures and engines, which is applied in the direction of machines/engines, manufacturing tools, mechanical equipment, etc., can solve problems such as ISG motor installation difficulties, and achieve the effects of avoiding assembly interference, accurate and reliable positioning, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

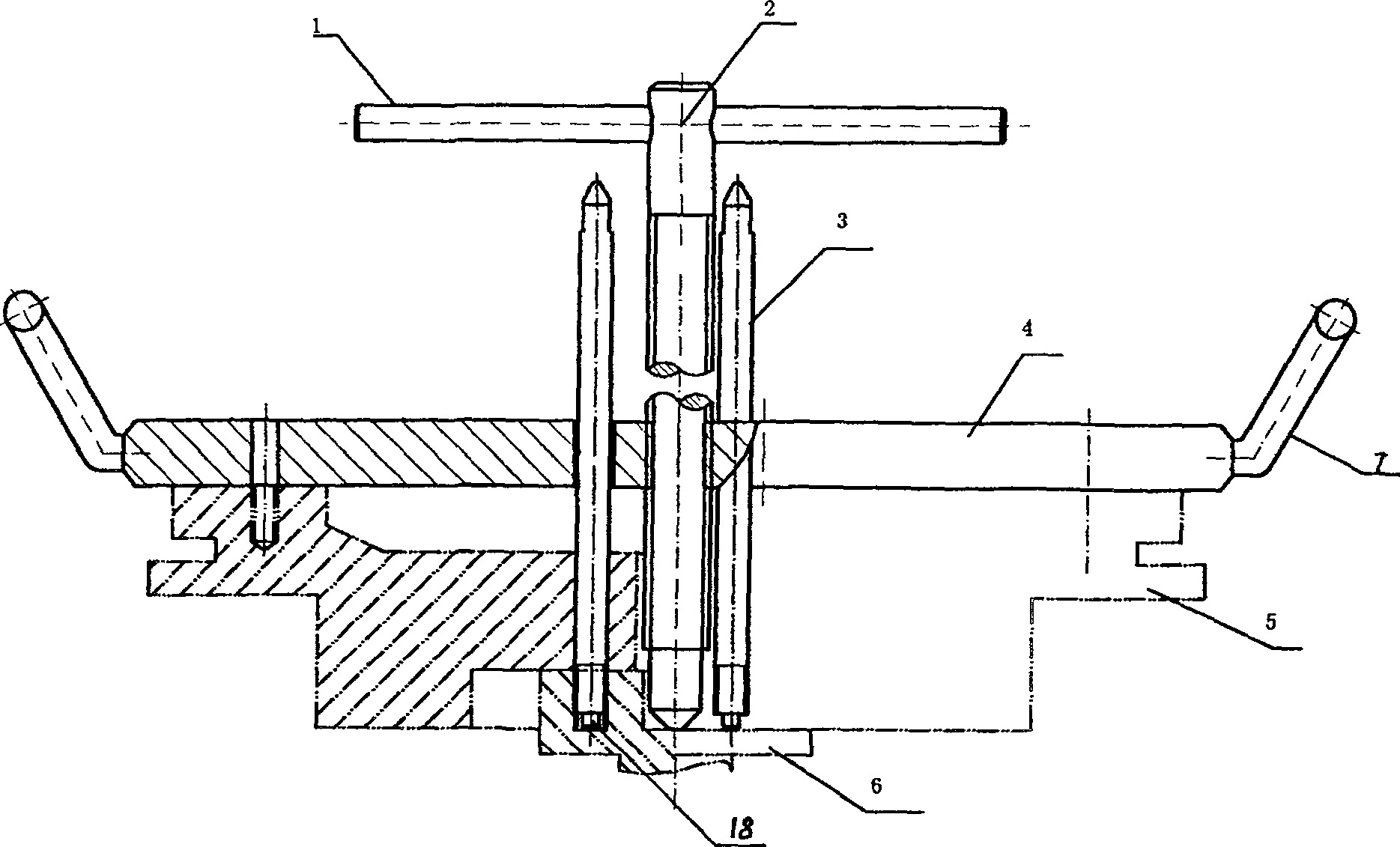

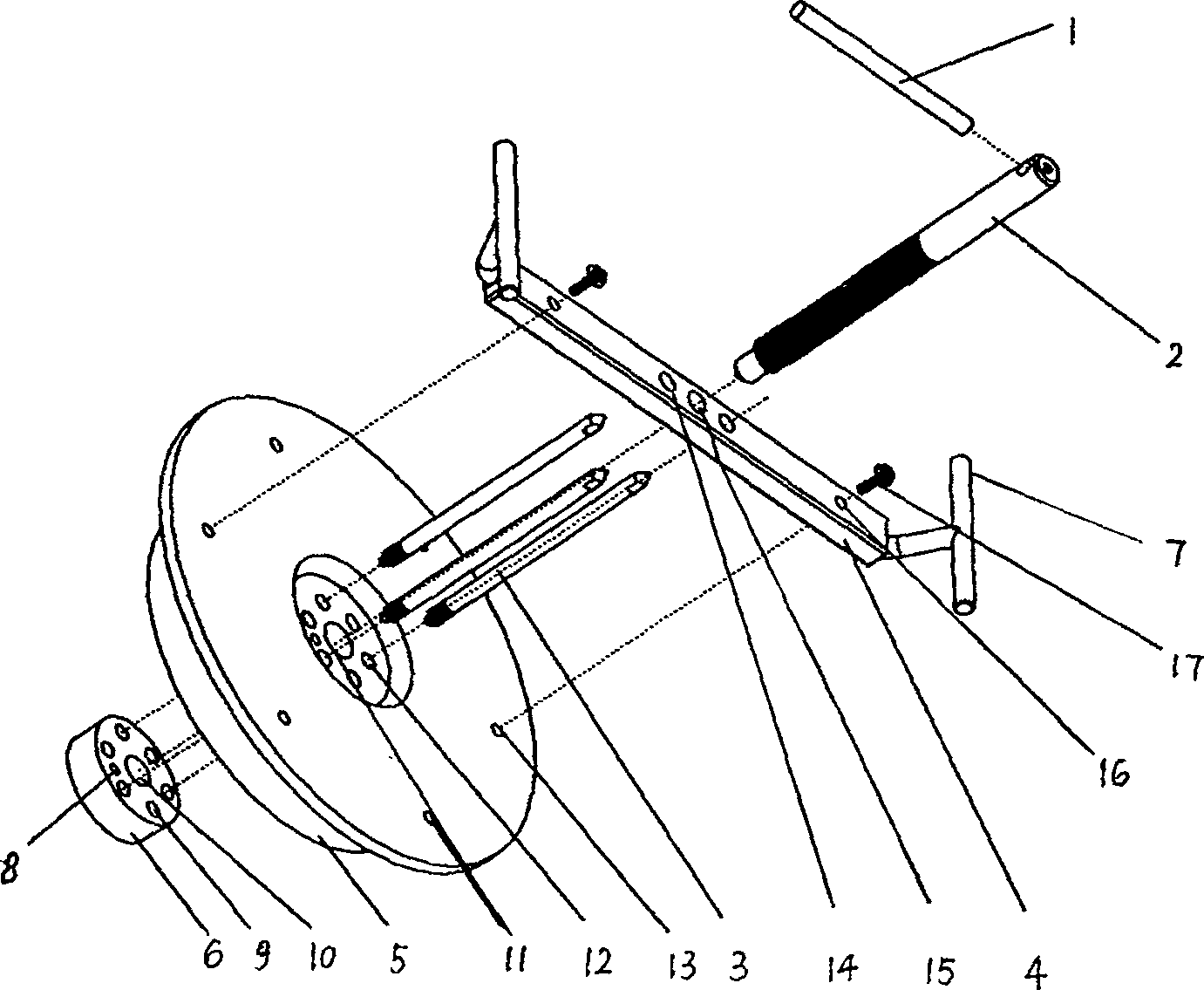

[0013] see figure 1 and figure 2 , The clamp is mainly composed of guide rod 3, support plate 4, screw mandrel 2 and handle 1. The lower end of the guide rod 3 has a thread that matches the mounting hole 9 of the engine crankshaft 6, and the top is designed with a thimble 18. There are three guide rods, which are respectively screwed into the three mounting holes 9 of the engine crankshaft 6, and the thimble 18 at the top reaches the screw hole Bottom plane. The upper end of the guide rod 3 is designed with a guide chamfer and a radial plane, which is convenient for the ISG motor rotor to be introduced and the guide rod to be tightened by an open-ended wrench. The support plate 4 is strip-shaped, with handles 7 at both ends, which is easy to use. Both ends of the support plate 4 have connecting screw holes 16 corresponding to the mounting screw holes 13 for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com