Outward-opening fireproof window locking structure

A fire-resistant window and locking technology, applied in the field of doors and windows, can solve the problems of easy corrosion, aluminum alloy corrosion, weakening heat transfer and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

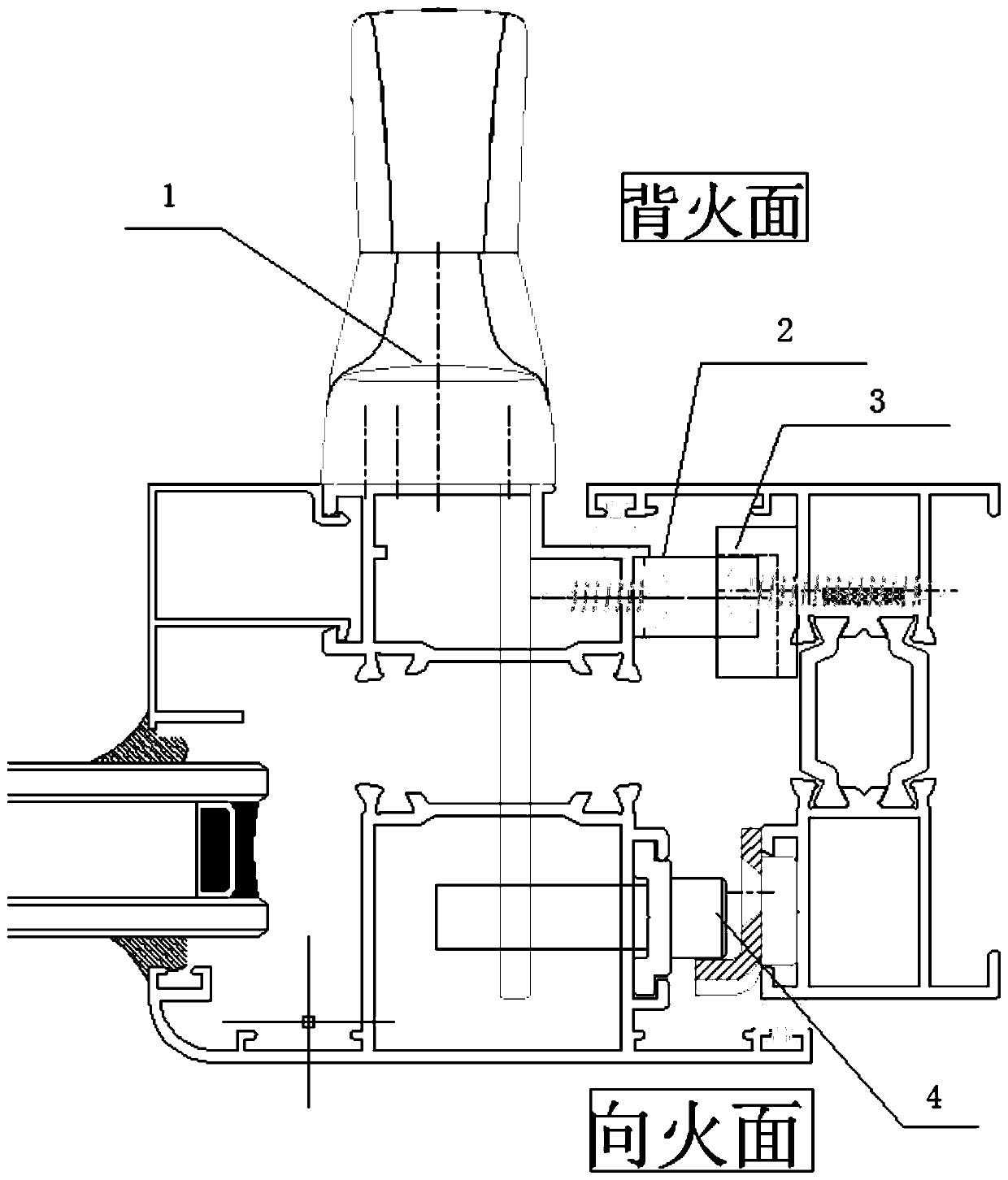

[0014] Embodiment: please refer to the accompanying drawings of the description,

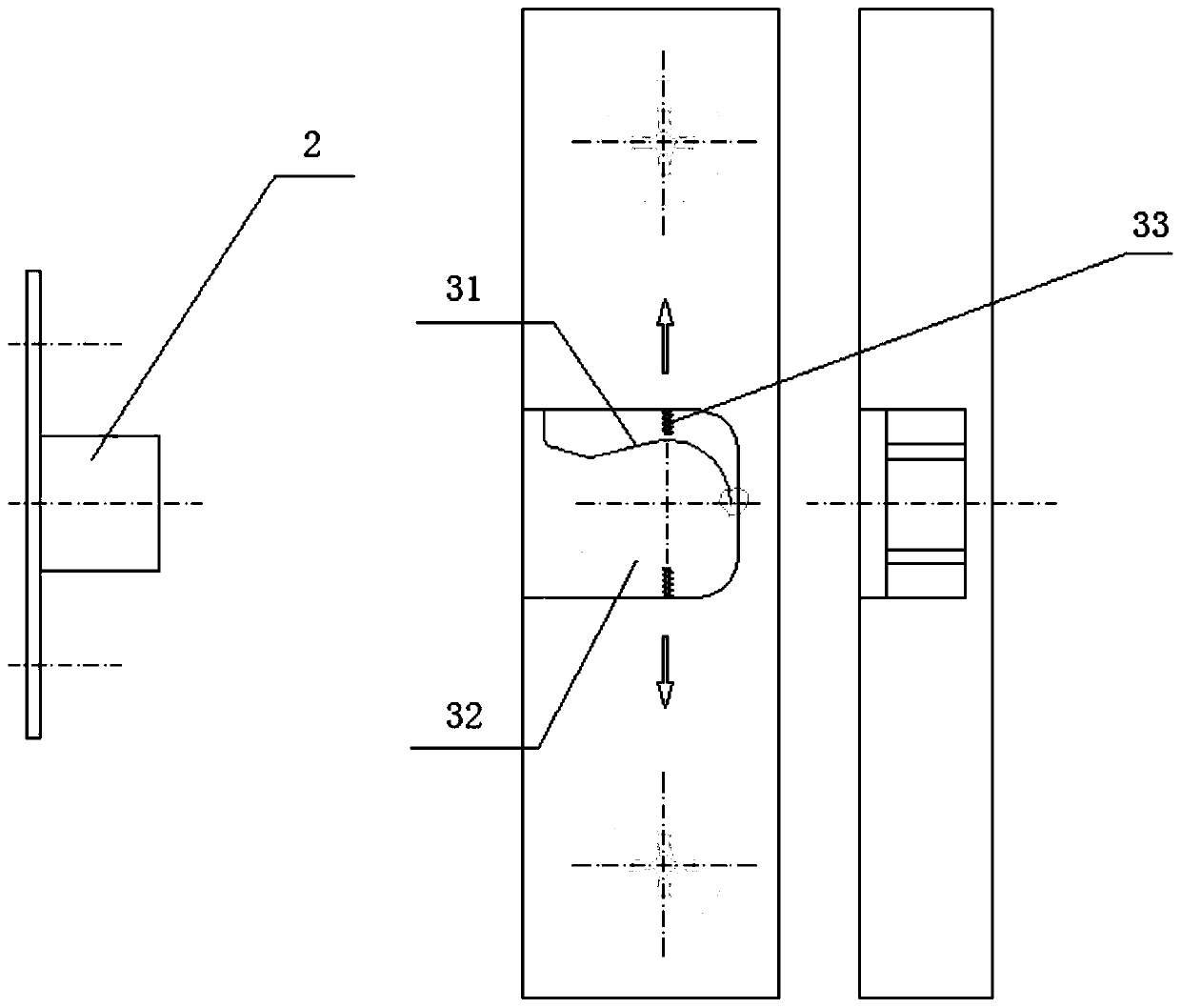

[0015] A locking structure for an outwardly opening fire-resistant window, including an aluminum alloy window frame. The aluminum alloy window frame is provided with a conventional locking mechanism 4 on the fire-facing surface. When a fire occurs, the conventional locking mechanism will fail on the fire-facing surface. There is a handle and a lock on the back side of the fire. It is characterized in that the handle and the lock are connected to an elastic locking mechanism through bolts. When a fire occurs, the elastic locking mechanism starts to work. The elastic locking mechanism includes a lock Column 2 and elastic bayonet lock seat 3, one side of elastic bayonet lock seat 3 is clamped with lock column 2 and the other side is connected to the aluminum alloy frame through a bolt, and the elastic locking mechanism includes lock column 2 and elastic bayonet lock seat 3 snapped together to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com