Device for continuously adjusting distance between diffuser and spray pipe of hypersonic speed free jet wind tunnel

A hypersonic, diffuser technology, used in measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of inability to achieve continuous adjustment of Δd, inability to store the adjustment section, time-consuming, labor-intensive, and safety. The effect of preparation efficiency, simple structure, and shortened adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

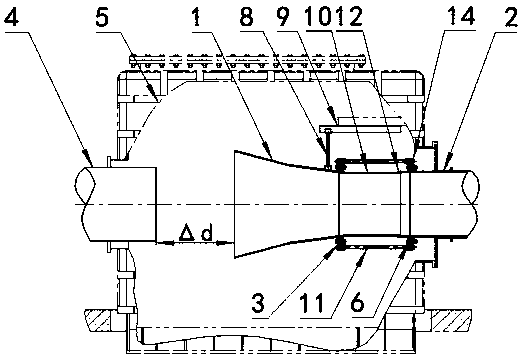

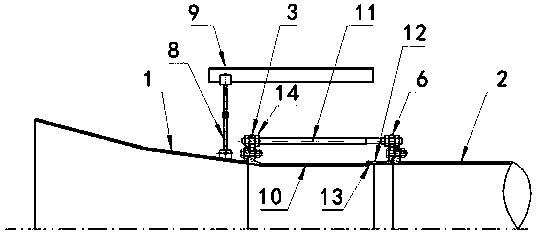

[0051] The device for continuously adjusting the distance between the diffuser and the nozzle of a hypersonic free-jet wind tunnel in this embodiment is installed in a hypersonic wind tunnel, and the distance between the inlet of the diffuser and the outlet of the nozzle is continuously within the range of 1.1m to 1.8m. adjustable.

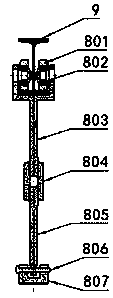

[0052] There are 4 threaded rods 11 and 16 adjusting nuts 14 in the device for continuously adjusting the distance between the hypersonic free jet wind tunnel diffuser and the nozzle in this embodiment.

[0053] The specific working process is as follows:

[0054] a. According to the needs of the wind tunnel test, determine the distance △d between the diffuser inlet and the nozzle outlet, measure the current distance △d1 between the diffuser inlet and the nozzle outlet, calculate the adjusted distance △d2=△d-△d1, determine Adjust the movement distance Δd2 of the nut 14;

[0055] b. Loosen the adjusting nuts 14 on the inside and outside of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com