Assembling press for vibrator of plate compactor

A technology of plate compactor and vibrator, which is applied in the field of press equipment, can solve the problems of large size, heavy vibration floor, and difficulty, and achieve the effects of ensuring safe operation, saving time in the assembly process, and reducing operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

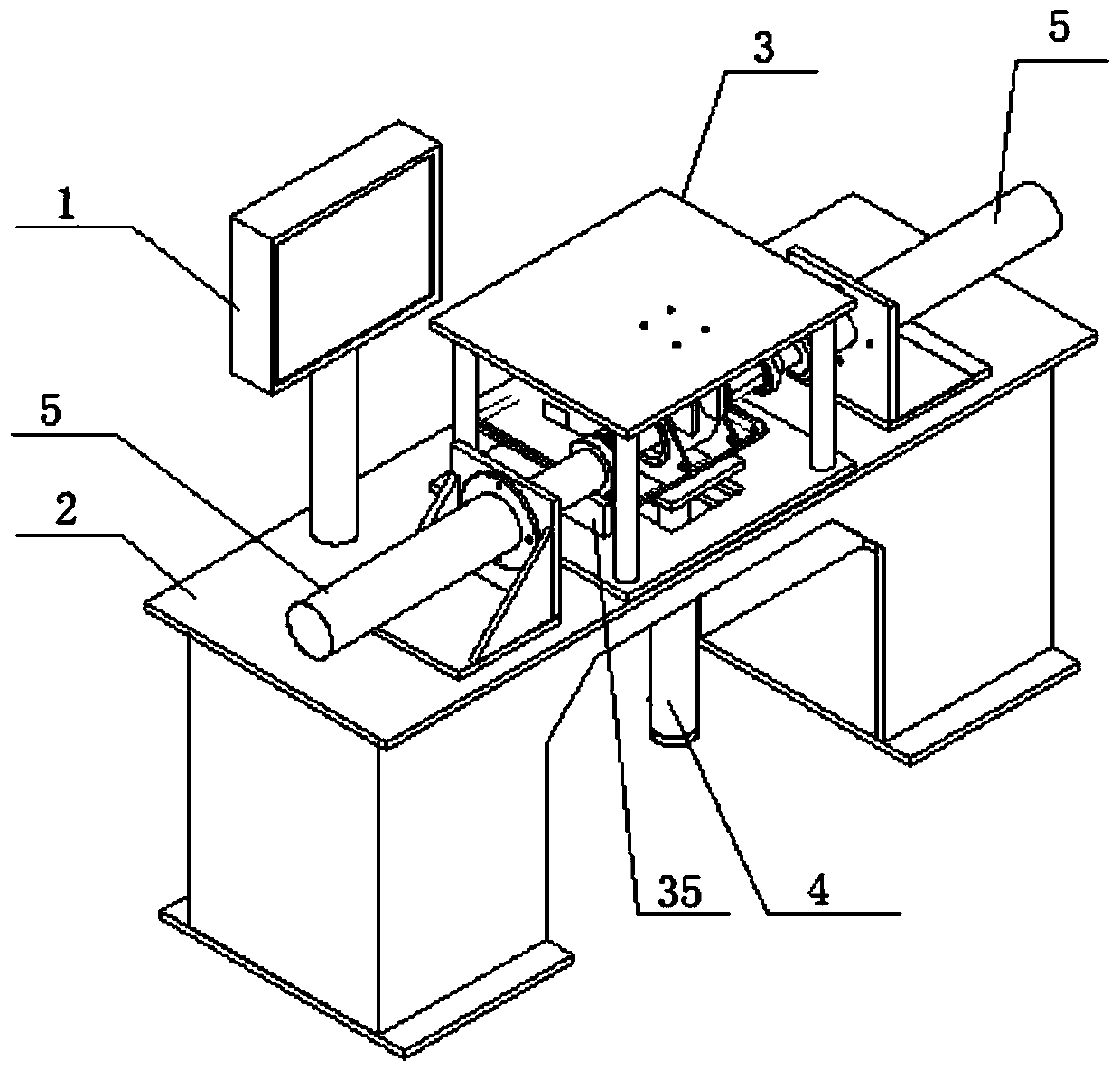

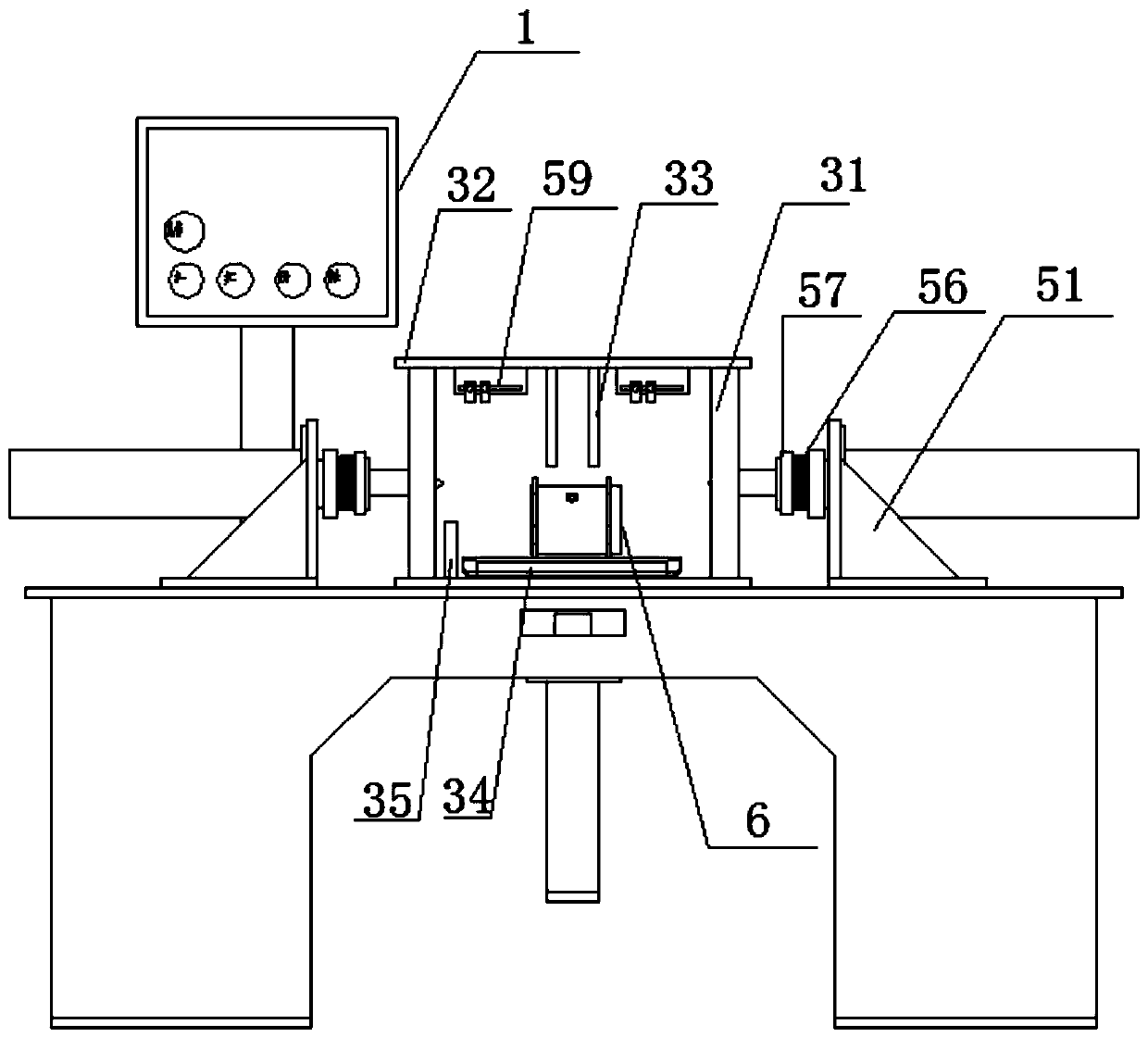

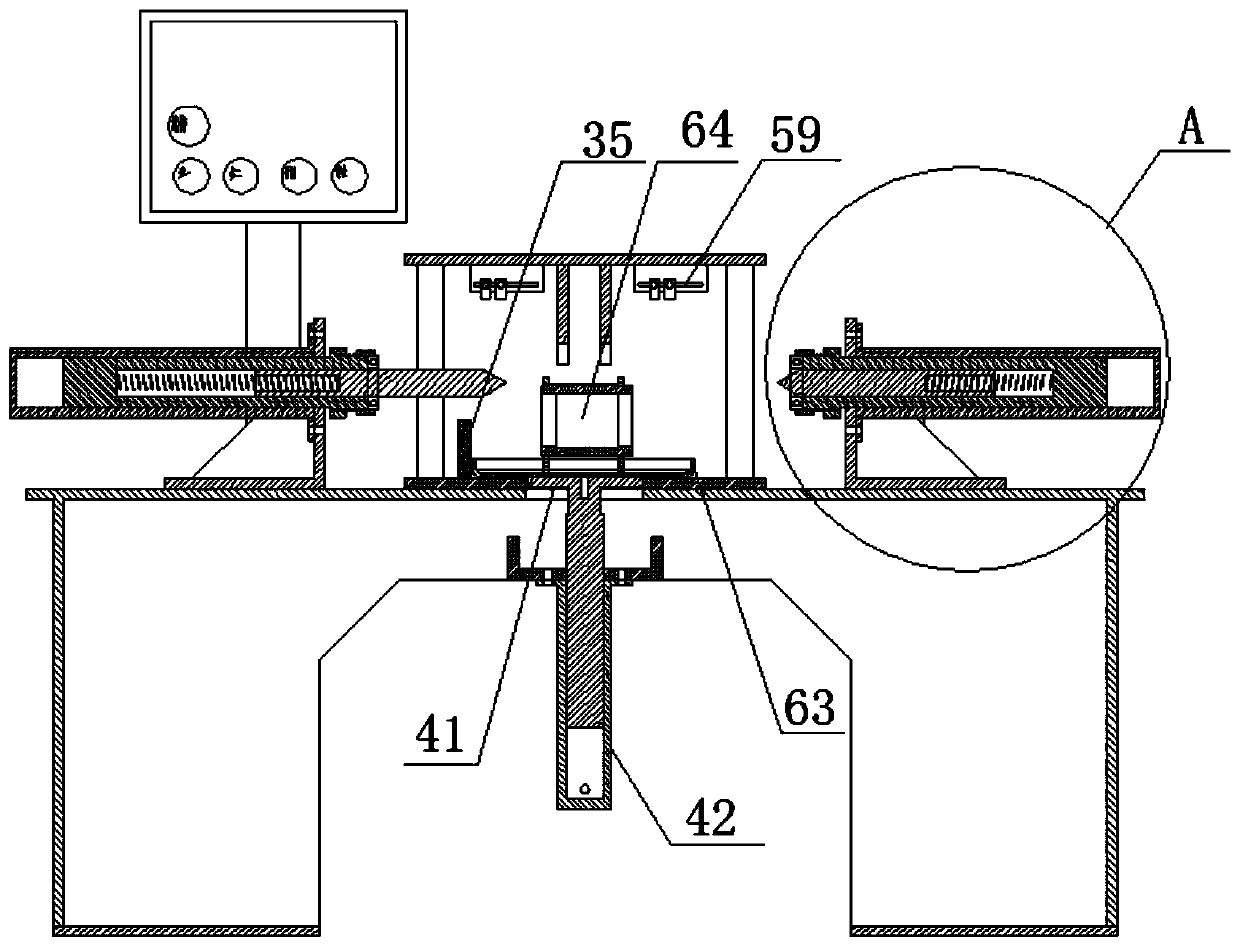

[0027] Such as Figure 1-8 As shown, a plate compactor vibrator assembly press according to the present invention includes a control device 1, a pressing table 2, a positioning device 3, a lifting adjustment device 4 and a pressing device 5, and the lifting adjustment device 4 and the pressing device The tightening device 5 is respectively connected with the control device 1; a positioning device 3 is provided above the press-fitting table 2, and a lifting adjustment device 4 is provided directly below the positioning device 3, and the lifting adjustment device 4 pushes the plate compactor box 6 moves upward to withstand the positioning device 3; the two ends of the positioning device 3 are respectively equipped with a compression device 5, and the two compression devices 5 compress or loosen the plate compactor box 6 from both ends.

[0028] Wherein, the pressing device 5 includes a pressing bracket 51, a pressing oil cylinder 52, a top 53, a pressing spring 54, a travel swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com