An injection molded toothbrush automatic separation and grinding device

An automatic separation and toothbrush technology, applied in the direction of grinding machines, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of scratching hands, cumbersome and inconvenient manual operation process, and low efficiency of separation and grinding , to achieve the effects of prolonging the use time, good practicability and innovation, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments.

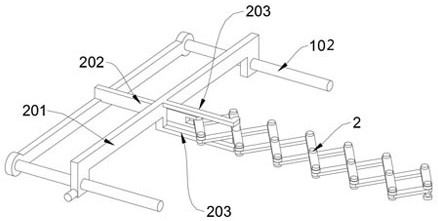

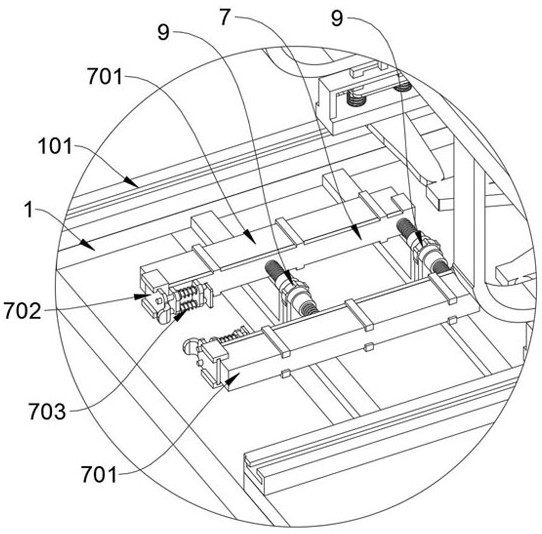

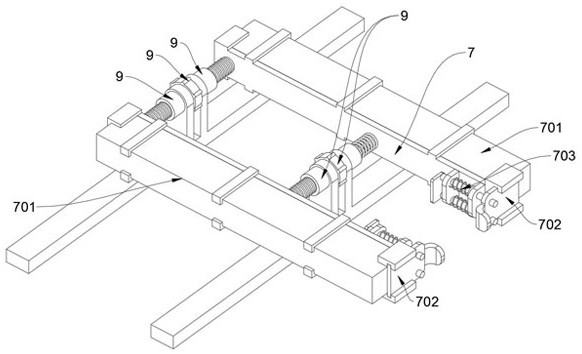

[0030] See Figures 1 through 10, one embodiment of the present invention provided: an injection molded toothbrush automatic separation and grinding apparatus, comprising a table panel 1, scissor jacking mechanism 2, toothbrush forming parts 4, a positioning plate 6, a card frame 7 and a nail frame 10, the table panel 1 is left and right spaced symmetrically supported by two, and two table panels 1 top front side symmetrically mounted with two sets of U-shaped top plates 3; table panel 1 includes a track slat 101 and a positioning axis 102, both table panels 1 within the bottom are evenly spaced mounted with two rail strips 101, Track stri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap