A prefabricated assembled concrete beam-column joint structure and its construction method

A technology of beam-column joints and prefabricated assembly, which is applied in the direction of building construction and construction, can solve the problems of weak lateral restraint of prefabricated components, poor integrity of joint joints, inconvenient maintenance and removal, etc., so as to facilitate structural maintenance and operation. Dismantling construction, improving construction efficiency, and improving the effect of restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

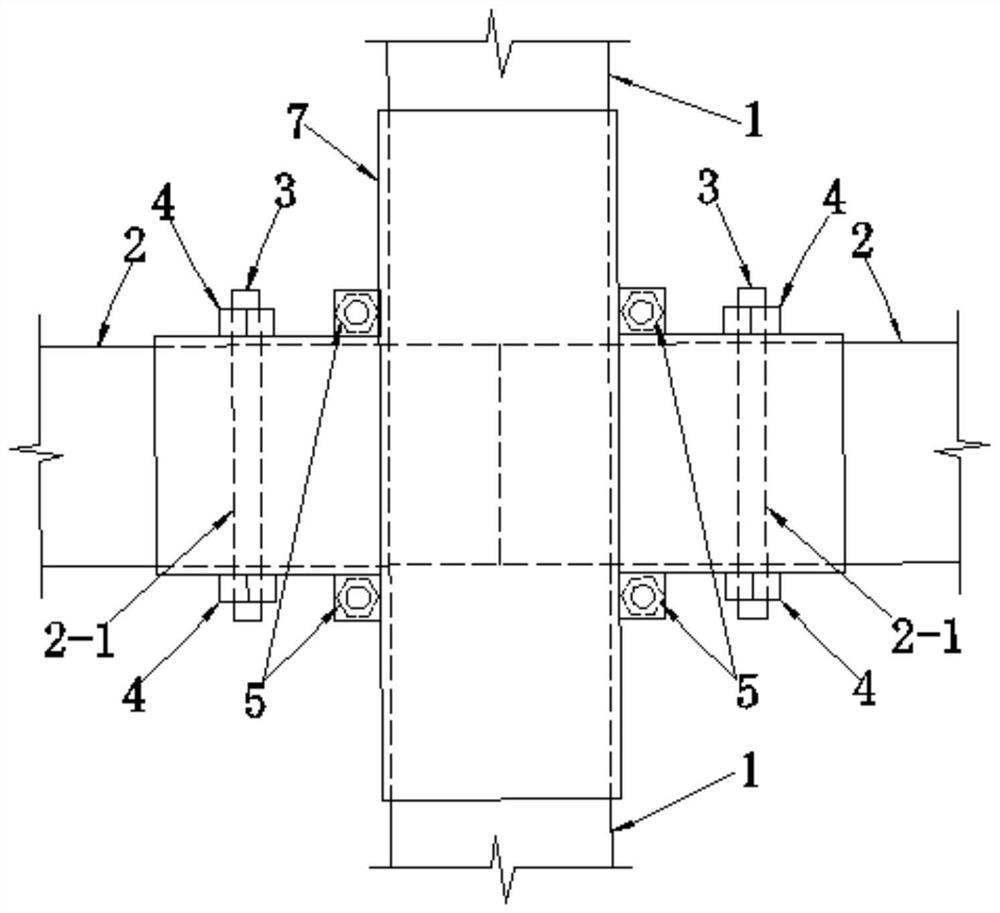

[0062] Both the first two-way restraint connector 6 and the second two-way restraint connector 7 are similar to "cross buttons", and the two-way restraint sleeve formed is a cross-shaped two-way restraint sleeve.

[0063] Method 1: applicable to all beam-column joints;

[0064] (1) hoist the prefabricated beam 2 on the left side and the prefabricated beam 2 on the right side to the corresponding positions on the left and right sides above the prefabricated column 1 on the lower floor respectively with a crane;

[0065] (2) Use a crane to hoist the first two-way restraint connector 6 to the front or rear of the prefabricated column 1 and the prefabricated beam 2 and attach it, and then connect the first threaded connector 3 through the vertical through hole 2-1 and the second The connector through hole 6-2 of a two-way constraint connector 6 is fastened with a nut 4;

[0066] (3) hoist the second two-way restraint connector 7 to a position facing the first two-way restraint co...

Embodiment 2

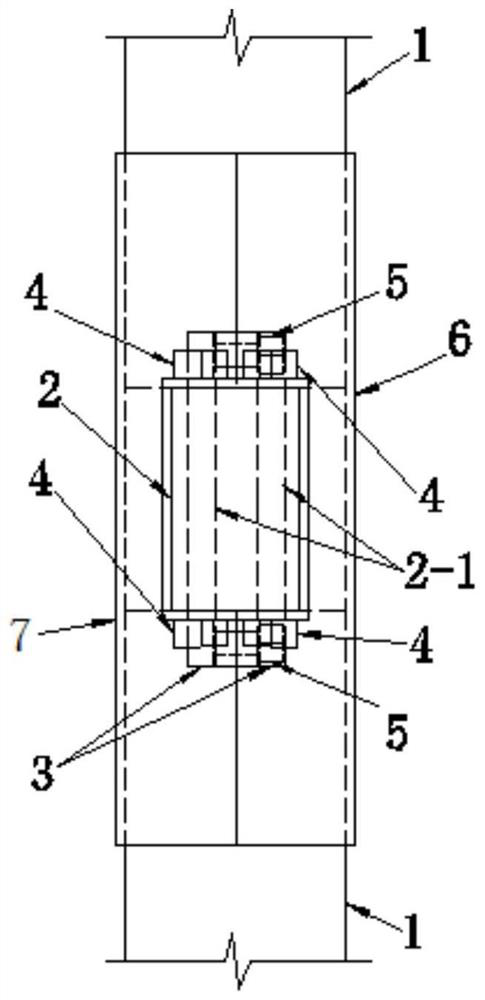

[0073] Both the first two-way restraint connector 6 and the second two-way restraint connector 7 are T-shaped, and the two-way restraint sleeve formed is a T-shaped two-way restraint sleeve, which is suitable for the edge nodes of the middle layer of the building.

[0074] Method 1: applicable to all beam-column joints;

[0075] (1) Hoist the prefabricated beam 2 on the left or right side to the corresponding position above the prefabricated column 1 on the lower floor with a crane;

[0076] (2) Use a crane to hoist the first two-way restraint connector 6 to the front or rear of the prefabricated column 1 and the prefabricated beam 2 and attach it, and then connect the first threaded connector 3 through the vertical through hole 2-1 and the second The connector through hole 6-2 of a two-way constraint connector 6 is fastened with a nut 4;

[0077] (3) hoist the second two-way restraint connector 7 to a position facing the first two-way restraint connector 6 with a crane, and ...

Embodiment 3

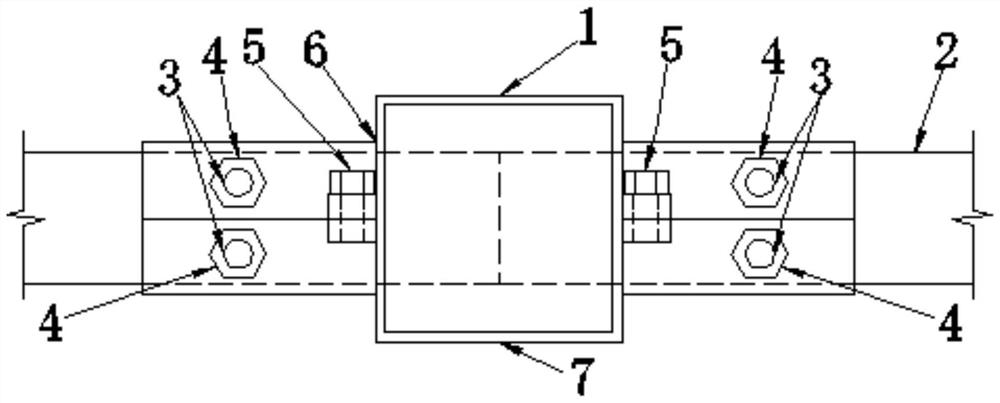

[0084] Both the first two-way restraint connector 6 and the second two-way restraint connector 7 are L-shaped, and the two-way restraint sleeve formed is an L-shaped two-way restraint sleeve, which is suitable for edge nodes on the top floor of a building.

[0085] Method 1: applicable to all beam-column joints;

[0086] (1) Hoist the prefabricated beam 2 on the left or right side to the corresponding position above the prefabricated column 1 on the lower floor with a crane;

[0087] (2) Use a crane to hoist the first two-way restraint connector 6 to the front or rear of the prefabricated column 1 and the prefabricated beam 2 and attach it, and then connect the first threaded connector 3 through the vertical through hole 2-1 and the second The connector through hole 6-2 of a two-way constraint connector 6 is fastened with a nut 4;

[0088](3) hoist the second two-way restraint connector 7 to a position facing the first two-way restraint connector 6 with a crane, and thread th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com