Explosion-proof performance test device and test method for explosion-proof permanent magnet electric roller

A technology of electric drum and testing device, which is applied in the direction of measuring device, material explosiveness, strength characteristics, etc., to achieve the effect of being conducive to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

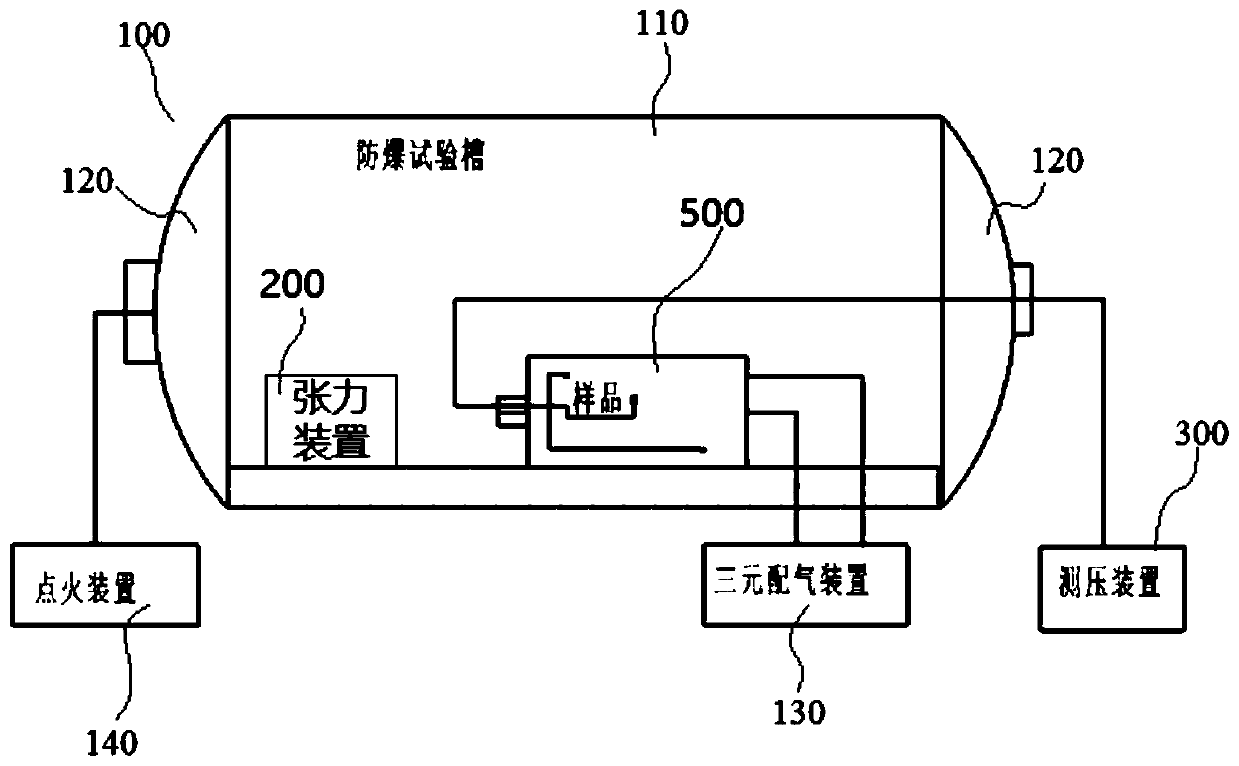

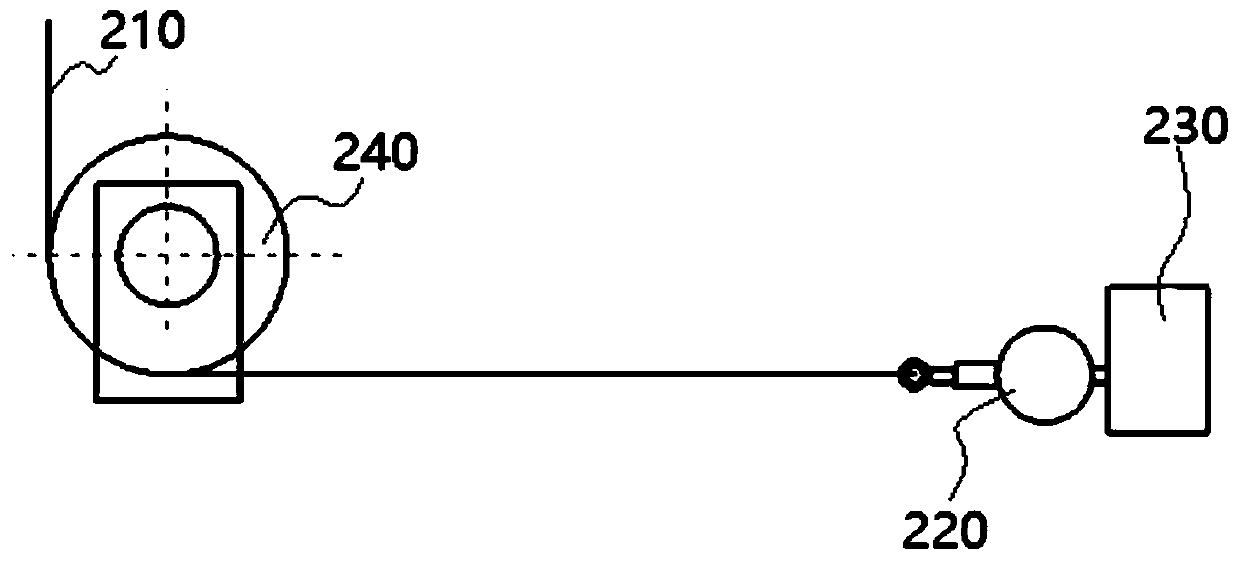

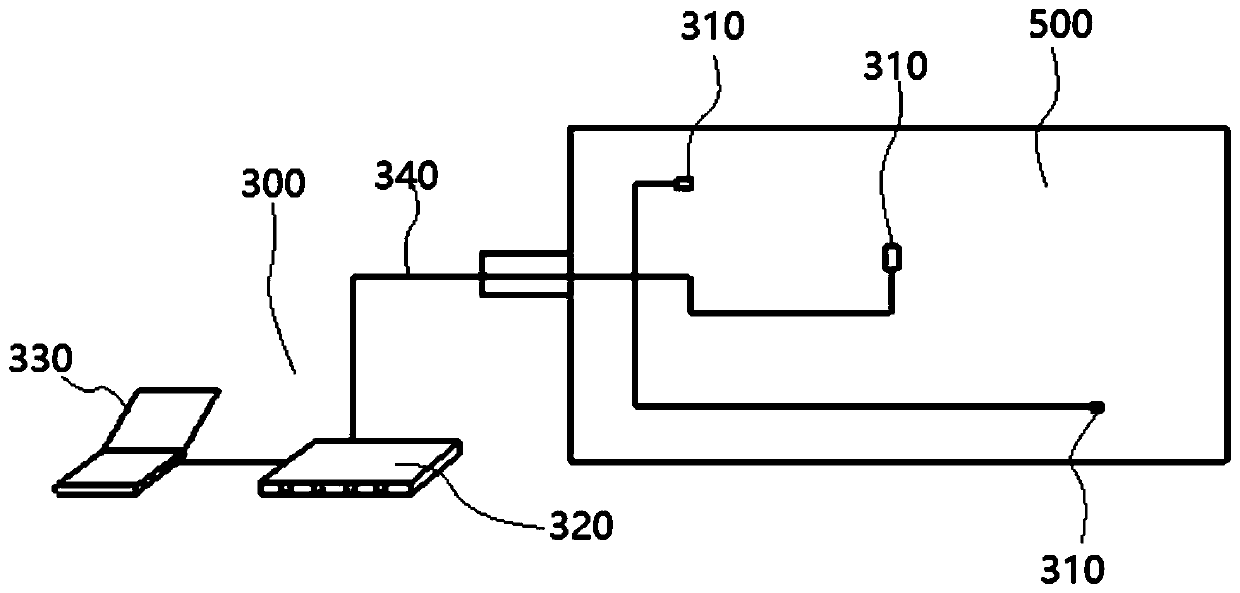

[0031] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0032] The flameproof permanent magnet electric drum shaft does not rotate, but the shell rotates. The inner wall of the shell is inlaid with permanent magnets to act as the motor rotor function. At the same time, the shell is not only an explosion-proof shell, but also bears pressure and torque, and bears torque and radial force through the web. It is necessary to study whether the tens of tons of tension of the tape is wrapped on the side of the permanent magnet electric drum about 1 / 2 of the drum, and whether the alternating force on the surface of the electric drum as the drum rotates at a low speed will affect the explosion-proof gap of the permanent magnet electric drum. Does the loss of explosion affect the operating performance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com