A medical waste classification treatment device and treatment method

A technology for medical waste and grading treatment, applied in water/sewage multi-stage treatment, filtration treatment, special treatment targets, etc. Divided process, enhanced drying effect, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

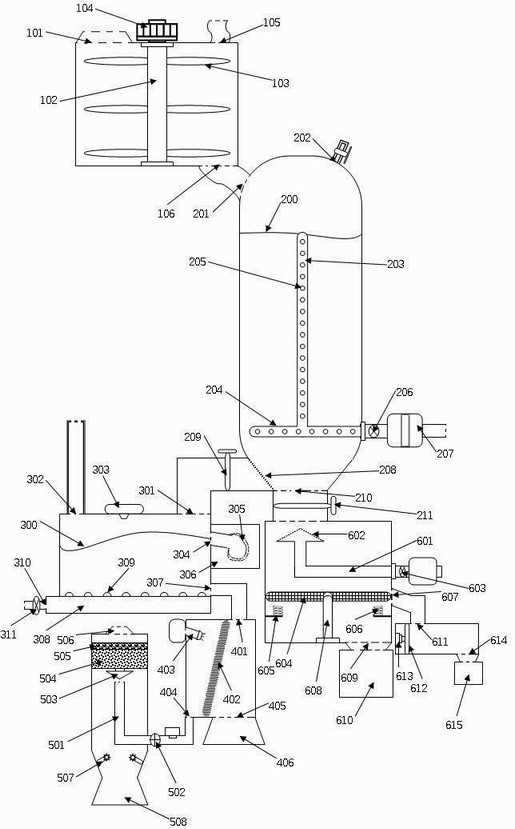

[0036]Further explanation in conjunction with the drawings:figure 1A schematic structural diagram of the internal view of the medical waste grading treatment device of the present embodiment, including a mixing chamber, a high pressure hydrolyzed component, a sewage treatment member, and a mixing treatment member.

[0037]Such asfigure 1As shown, the mixing chamber includes a mixed cavity feed port 101, a stirring shaft 102, a stirring blade 103, a mixing motor 104, a mixed cavity inlet 105, and a mixing cavity outlet 106; the mixing cavity The inlet is disposed on the top wall of the mixing chamber for discharging the medical waste into the mixing chamber, the stirring shaft is disposed vertically in a mixed chamber, and the stirring blade is placed on the stirring shaft, stirring the motor The outer portion is provided outside the mixing chamber and is connected to the stirring shaft and the rotation of the stirring shaft is driven, and the mixing cavity is provided on the top wall o...

Embodiment 2

[0046]A medical waste grading treatment method, the method for performing the medical waste grading processing apparatus of Example 1, specifically comprising the steps of:

[0047]1) The medical waste is put into the mixing chamber by mixing the incident portions, and the stirring cavity is opened into the tap water, start the stirring motor, and open the mixing cavity of the mixing chamber after 5min, and discharge the material.

[0048]2) The material discharged from the mixing cavity is put into the high pressure tank through the high pressure tank, the high-pressure tank exhaust port is closed, the high pressure cans are released, the release valve is closed, the trachea is closed, When the material of the high pressure tank reaches 10% of the total volume, open the gas pipe and start the high pressure tank to enter the gas booster pump, adjust the wind temperature in the gas heating chamber to 115 ° C, and turn on the high-pressure tank exhaust port.

[0049]3) When the material of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com