Processing method of aluminum plate, aluminum plate and splicing tooling thereof

A processing method and technology for aluminum plates, which are applied in workpiece clamping devices, connecting components, manufacturing tools, etc., can solve the problems of multiple welding scars, high processing costs, and difficult processing of aluminum plates, so as to increase the overall weight and reduce procurement costs. , the effect of high fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

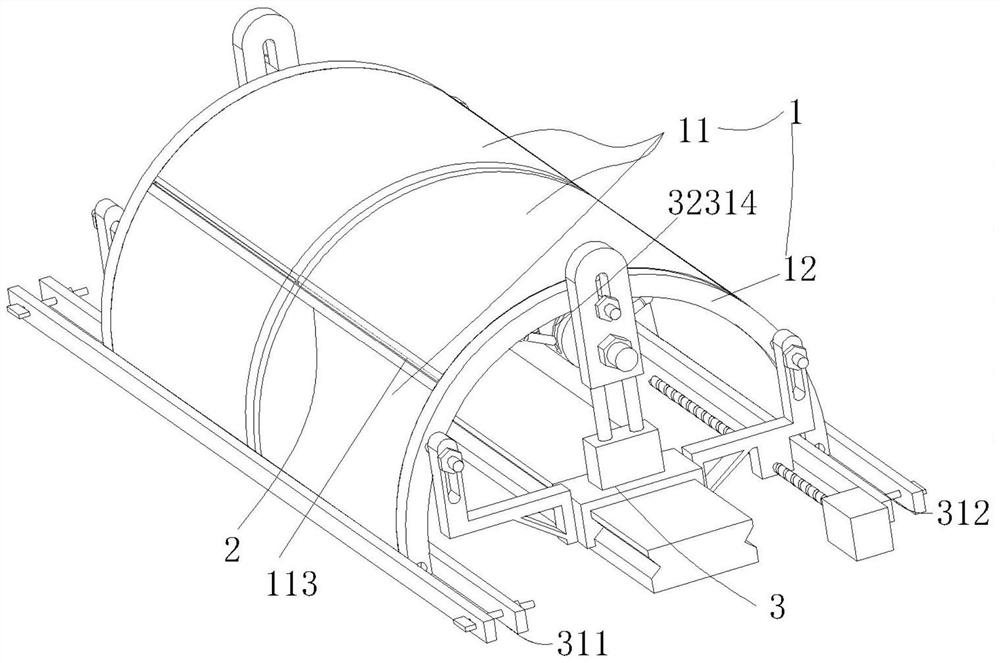

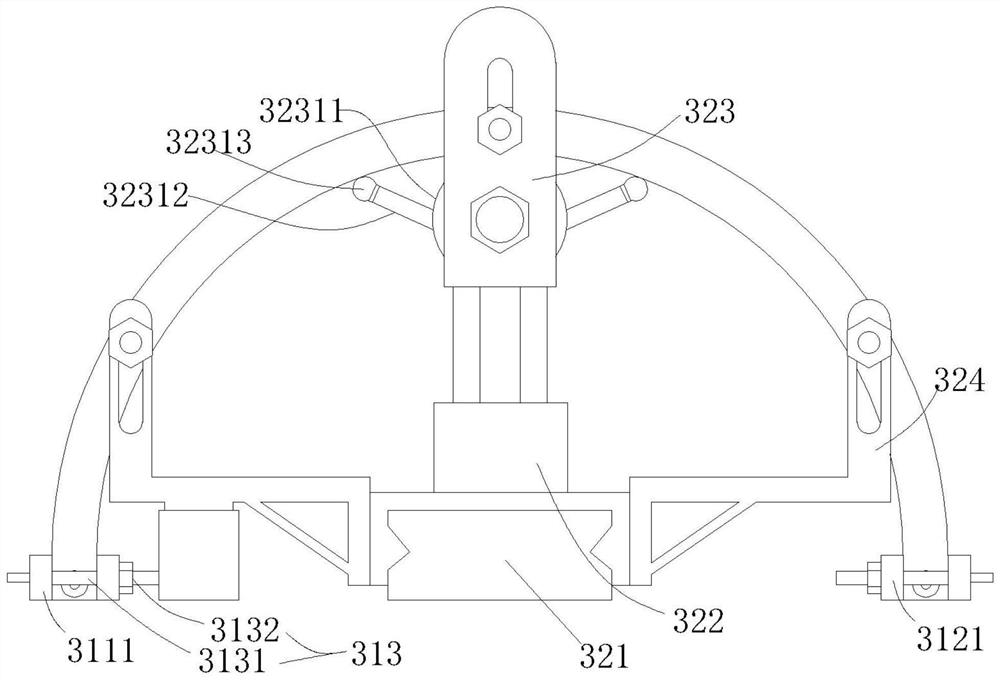

[0040] Such as Figure 1-7 Shown, the step of the processing method of this aluminum plate is:

[0041] S1. On-site measurement: The staff inspects the construction location on the spot, conducts on-site measurement and records the data;

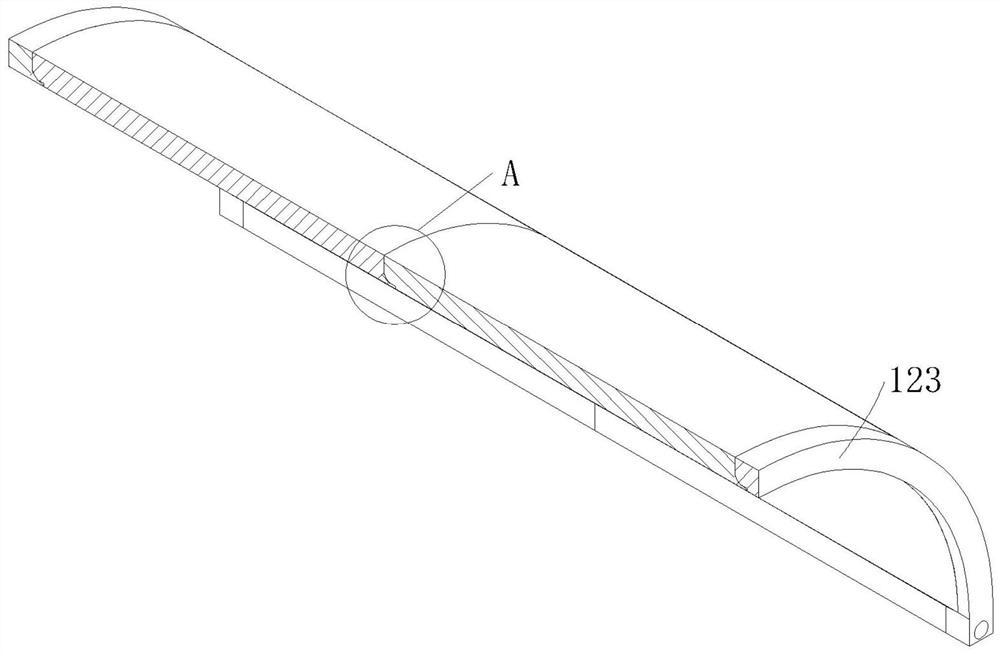

[0042] S2. Mathematical modeling: establish a mathematical model of the arc-shaped aluminum plate 1 according to the recorded data, slice the mathematical model of the arc-shaped aluminum plate 1, and slice the arc-shaped aluminum plate 1 to obtain multiple small-area curved aluminum plates 11;

[0043] S3. Process the aluminum billet into multiple curved aluminum plates 11 and multiple reinforcing sheets 2 by using a machine tool and a bending machine;

[0044] S4, each curved surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com