Steel large formwork integrally designed with reserved boxes and construction method of steel large formwork

A technology of large formwork and reserved box, which is applied in the field preparation of formwork/formwork/work frame, formwork/formwork components, and building components, can solve the problems of positioning deviation and affecting the climbing of the steel platform formwork, etc. Achieve the effect of ensuring positioning, avoiding contamination of bolt holes, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

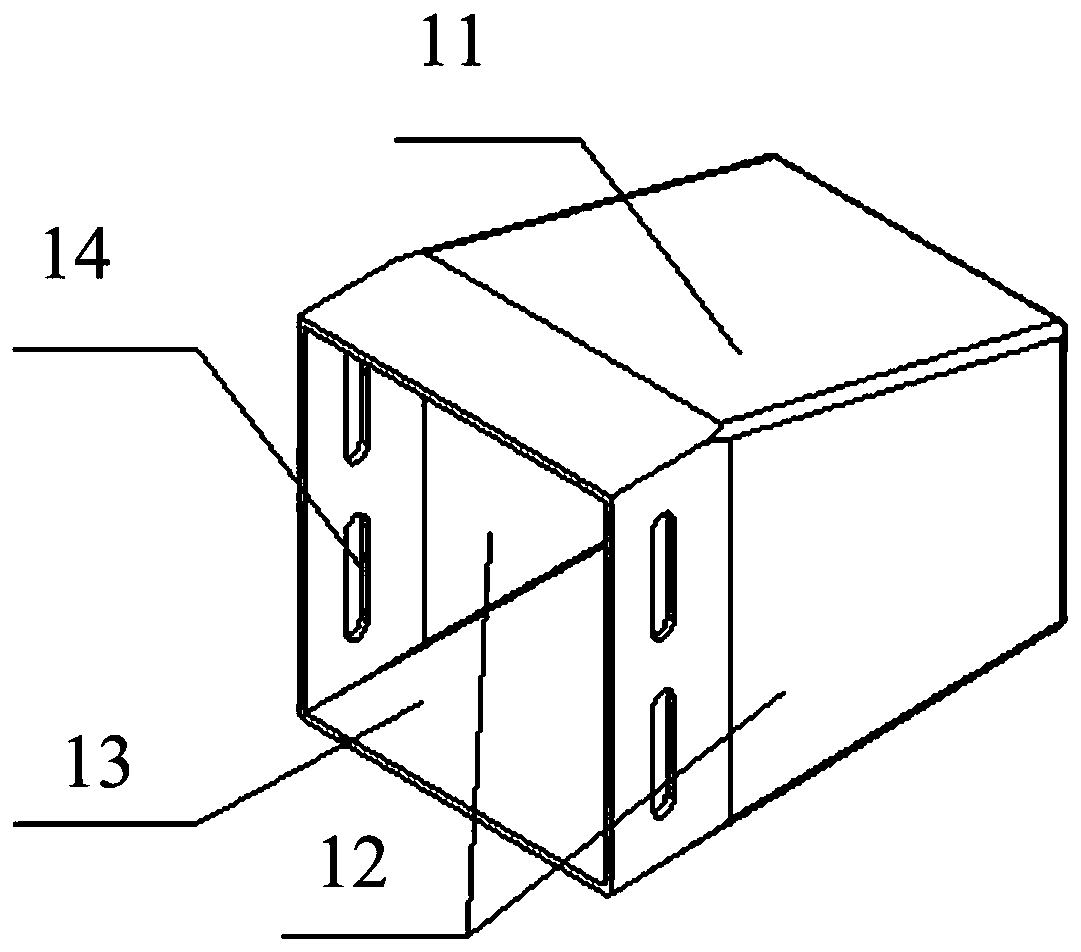

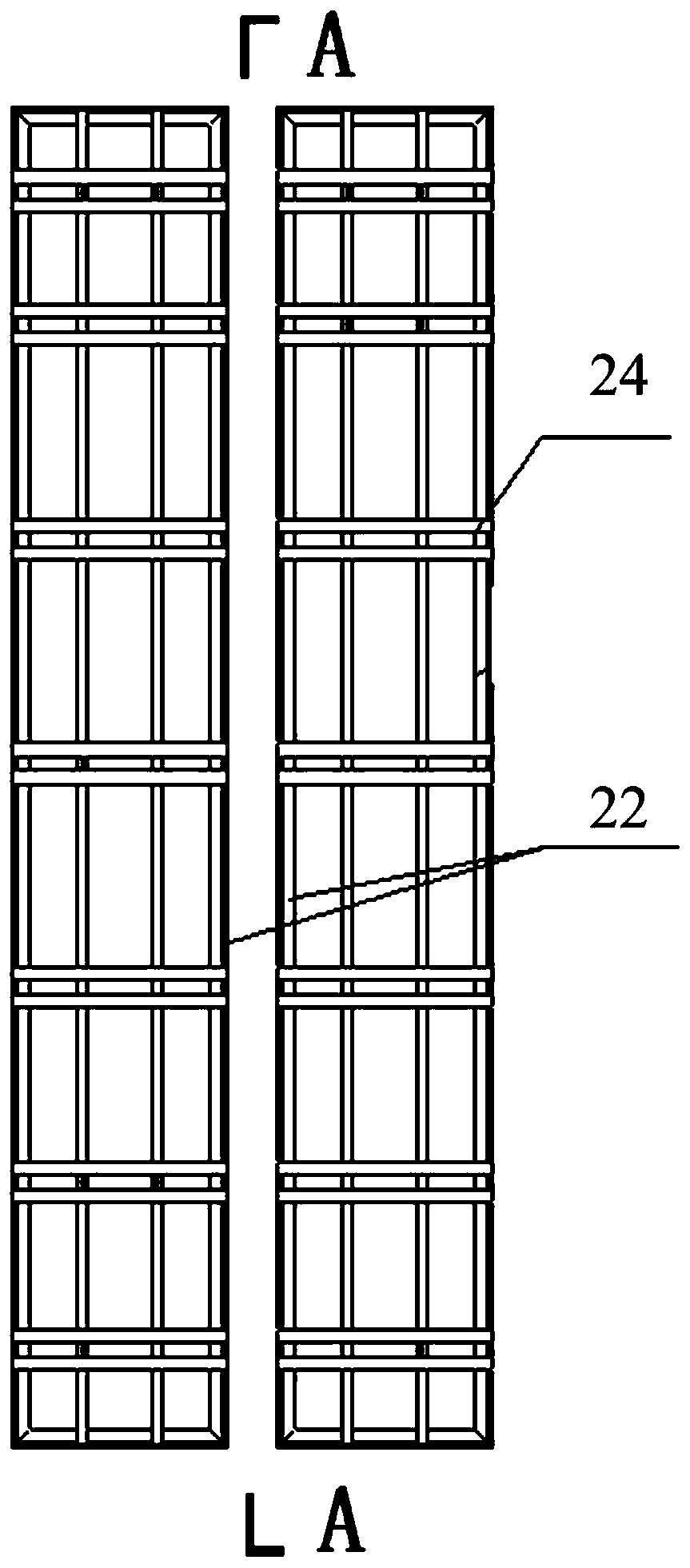

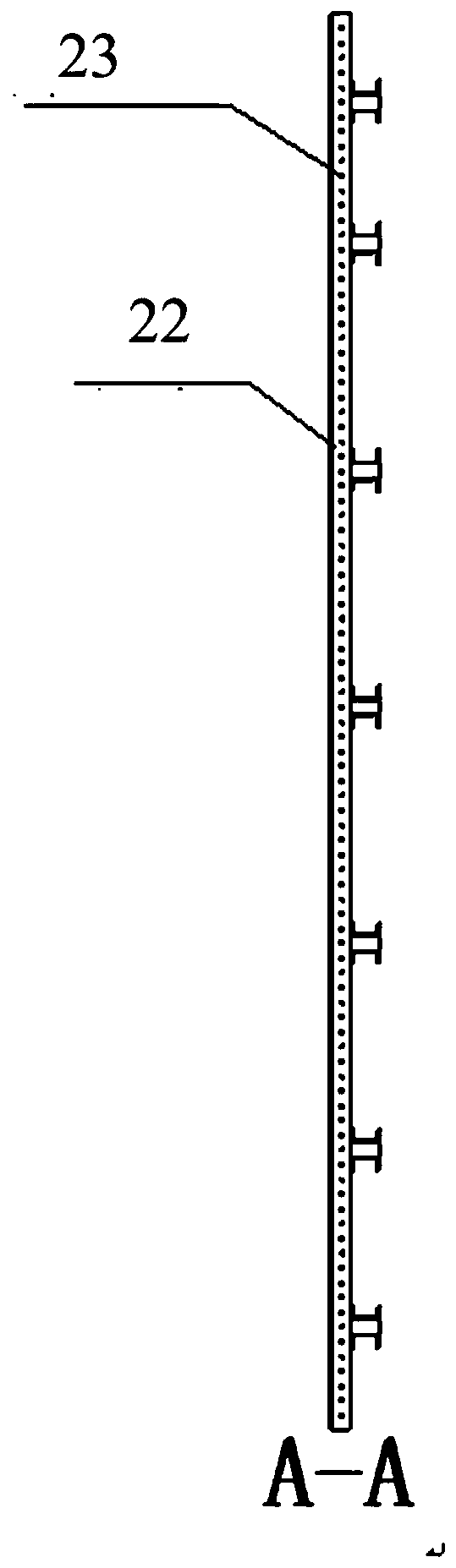

[0034] combine Figure 1 to Figure 6 Describe the structural composition of the large steel formwork designed integrally with the reserved box of the present invention.

[0035] Please refer to Figure 1 to Figure 6 , a large steel formwork designed integrally with the reserved box, comprising a reserved box 10 and a formwork component, both sides of the reserved box 10 are longitudinally provided with oblong holes 14, and the reserved box 10 is located at the reserved hole of the corbel; the template The component includes a pair of formwork bodies 21 and angle steel longitudinal ribs 22. The formwork body 21 has a long hole longitudinally at the position corresponding to the corbel, and the angle steel longitudinal ribs 22 are arranged on both sides of the long hole. Connecting holes 23 are set vertically at intervals, and the connecting holes 23 match the oblong holes 14, so that several reserved boxes 10 are sandwiched between two formwork bodies 21 at equal intervals, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap