High-ground-temperature tunnel ventilation cooling device and advanced cooling method

A technology of tunnel ventilation and cooling device, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve the problem of not cooling down, and achieve the effect of reducing sultry feeling, increasing ventilation, and improving working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In the related technology, the cooling measures taken in the high ground temperature tunnel are only to increase the ventilation in the tunnel to improve the ventilation environment in the tunnel, but in fact it does not have a good cooling effect. The construction environment in the tunnel It is still harsh, the environment is high, and the high ground temperature environment still exists.

[0047] The inventor found that relatively low-temperature air outside the tunnel is blown into the tunnel 400, and heat is exchanged and transferred due to the temperature difference, and the air has become hot air during the propagation process, resulting in limited effects of ventilation and cooling measures.

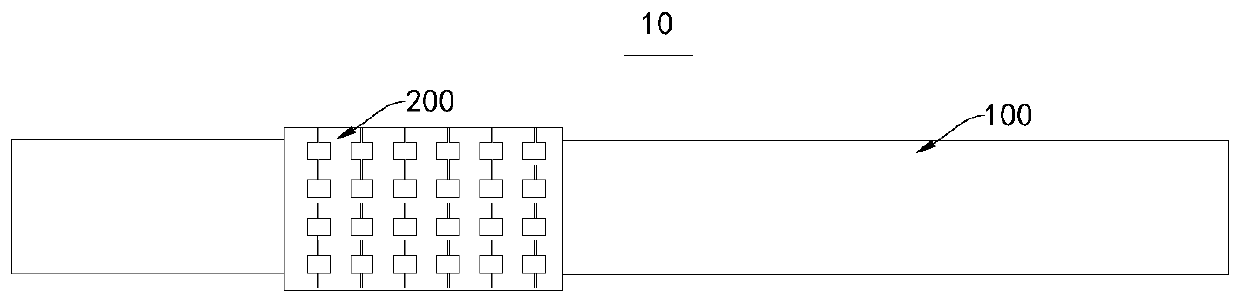

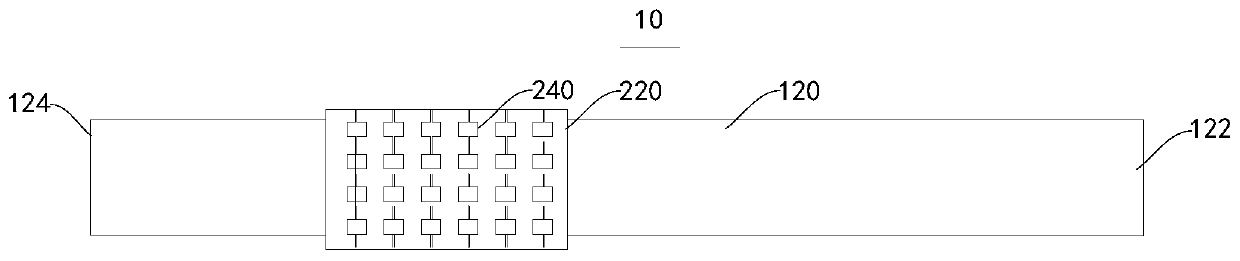

[0048] Based on this, the inventor provides a high ground temperature tunnel ventilation and cooling device 10, which includes a ventilation component 100 and a first refrigeration component 200, please refer to figure 1 , 2 .

[0049] Among them, the ventilation assembly 100 is ...

Embodiment 2

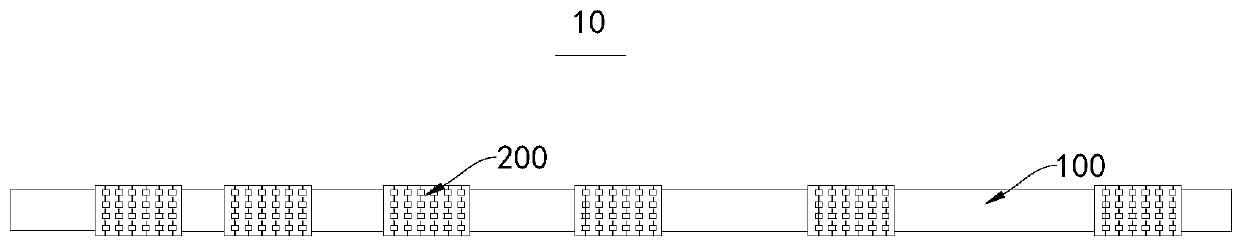

[0053] The device obtained through the above design can basically satisfy the use of tunnel cooling, but in order to further improve its function, the inventor has further improved the aforementioned high ground temperature tunnel ventilation cooling device 10, which can further improve the cooling effect.

[0054] See Figure 4 In the second embodiment of the invention, a ventilation cooling device 10 for a high ground temperature tunnel is also provided. The high ground temperature tunnel ventilation and cooling device 10 includes the high ground temperature tunnel ventilation and cooling device 10 provided in Embodiment 1, wherein the ventilation assembly 100 further includes a second ventilation pipe 140, and the second ventilation pipe 140 is detachably connected to the first ventilation pipe 120 . In addition, a second refrigeration assembly 300 is also included.

[0055] In the specific installation, the second ventilation pipe 140 is provided with a dovetail groove at one ...

Embodiment 3

[0058] See Image 6 In the third embodiment of the invention, a ventilation cooling device 10 for a high ground temperature tunnel is also provided. The high ground temperature tunnel ventilation and cooling device 10 includes the high ground temperature tunnel ventilation and cooling device 10 provided in Embodiment 1 or 2.

[0059] The inventor discovered during the study of the surrounding rock of the tunnel 400 that before the excavation of the tunnel 400, the surrounding rock was in a state of thermal equilibrium. During the excavation of the tunnel 400, a tunnel face was formed. The ventilation in the tunnel 400 resulted in airflow. The original thermal balance is out of balance, and a new thermal balance needs to be re-established. The surrounding rock near the tunnel face is continuously cooled. This kind of rock mass cooling extends from the tunnel face to the deep part of the rock mass until a new thermal balance is established. At a certain distance from the tunnel fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com