Active load reduction large wind electric generator blade

A technology for wind turbine blades and wind turbines, which is applied to wind turbines, wind turbines, and control of wind turbines that are consistent with the wind direction, can solve the problems of wind turbine blades being easily broken, and the wind load is not effectively reduced. Avoid breakage, reduce wind loads, and achieve smooth transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

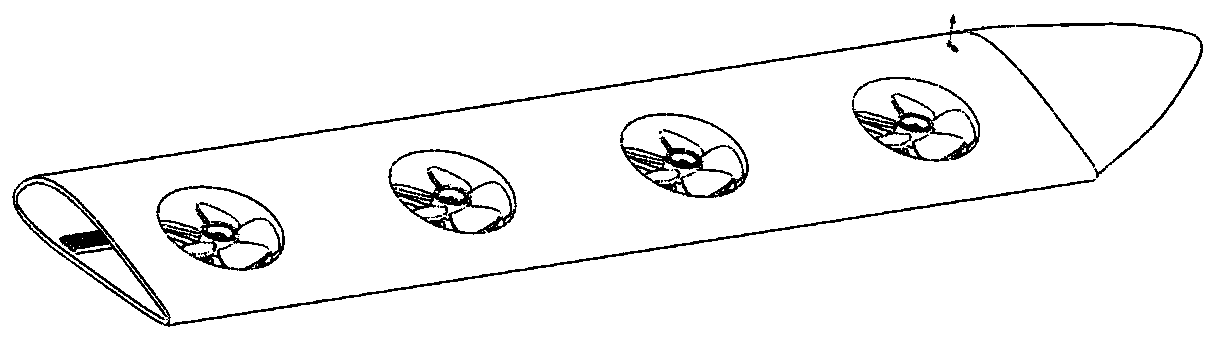

[0015] Such as figure 1 As shown, a large-scale wind generator blade for active load reduction in this embodiment includes a wind turbine blade 8 and a control circuit 9, wherein: it also includes a plurality of structural fans, and the structural fans are arranged in the wind turbine blade 8, The control circuit 9 is arranged in the wind turbine blade 8 and adhered to the inner wall. One end of the control circuit 9 is connected to several structural fans, and the other end is connected to the controller.

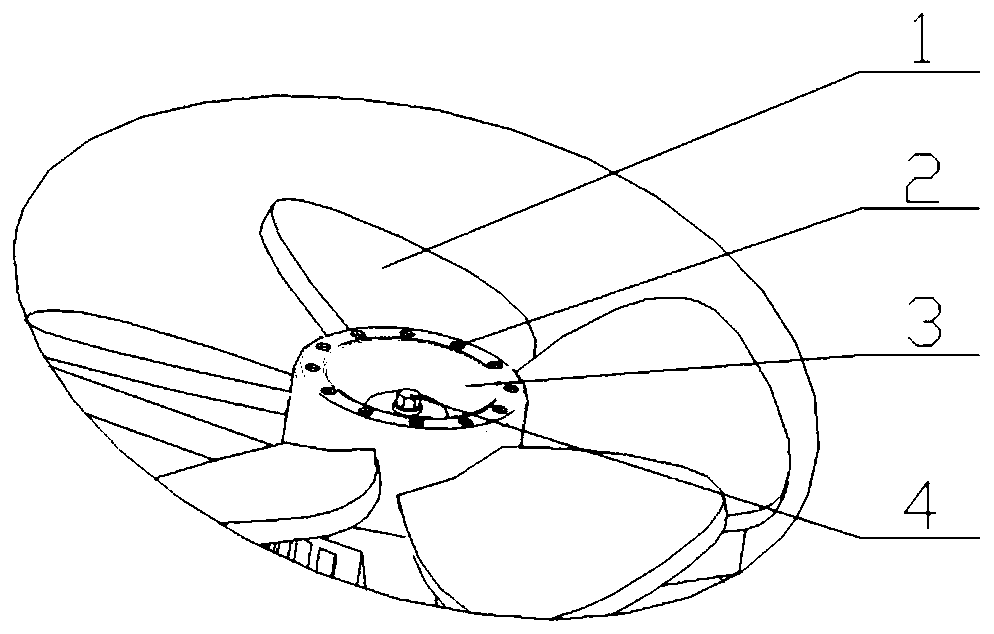

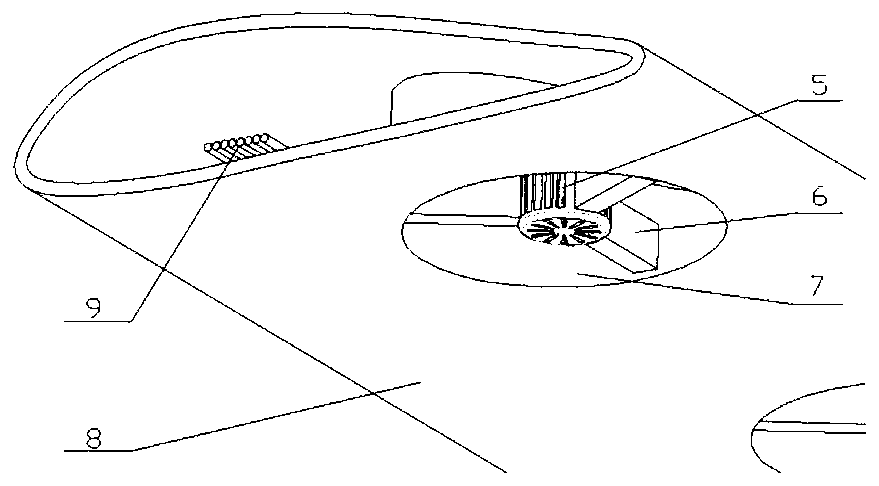

[0016] Such as figure 2 with image 3 As shown, the structural fan is composed of a fan blade 1, a fan blade fixing nut 2, a fan blade frame 3, a clamping screw 4, a motor 5, a bracket 6 and a structural frame 7, and the fan blade 1 passes through the fan blade fixing nut 2 Axially evenly installed on the fan blade frame 3; the fan blade frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com