Conductive connecting piece and multi-jack socket

A technology of conductive connection and socket, which is applied to the parts, connections, electrical components of connecting devices, etc., can solve the problems of increasing the width or thickness of connecting parts, material waste, etc., to avoid material waste, reduce costs, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the technical solutions and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

[0056] The conductive connector acts as a conductor inside the socket to conduct current. The following is combined with the attached figure 1 Instructions for the arrangement of the conductive connections in the socket:

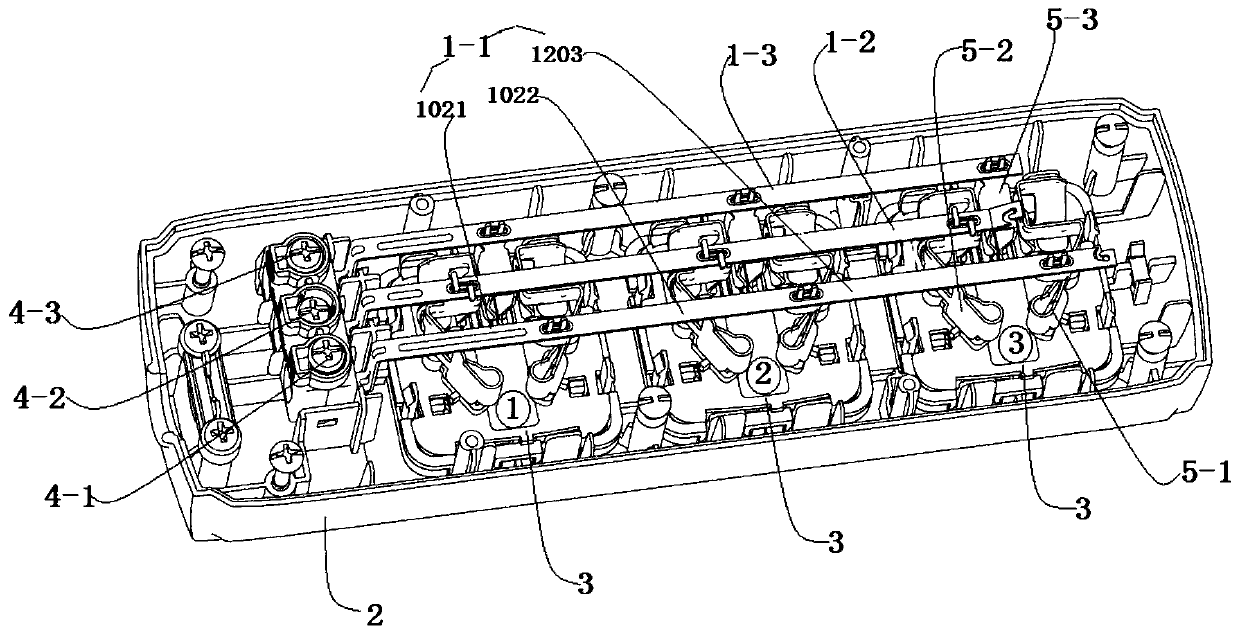

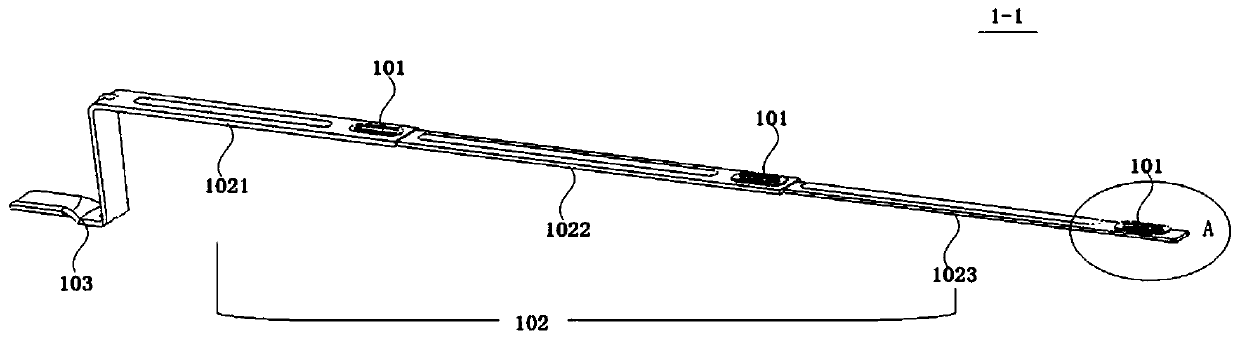

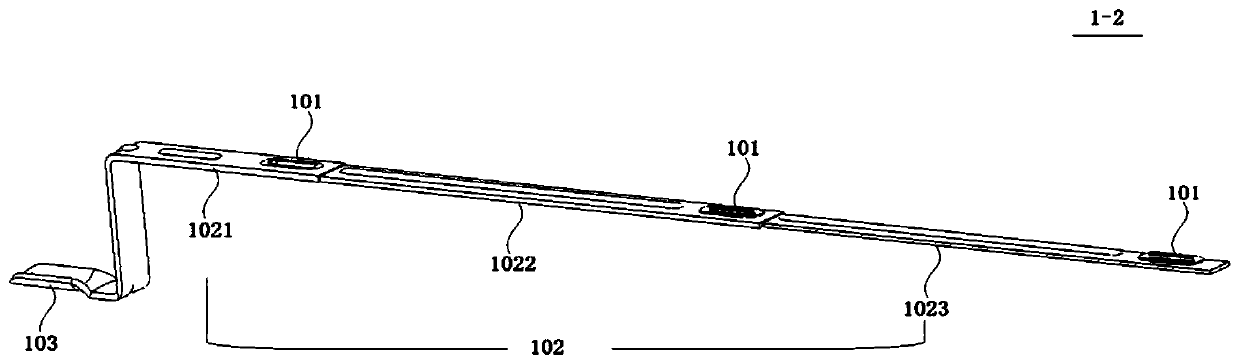

[0057] as attached figure 1 As shown, the three-level socket includes: a housing 2 ; a socket 3 on the housing 2 and connection terminals; and a conductive connector on the socket 3 . Wherein, the connection terminals include N (zero line) pole connection terminal 4-1, L (live line) pole connection terminal 4-2, E (neutral line) pole connection terminal 4-3; Connector 1-1, L pole conductive connector 1-2, E pole conductive connector 1-3.

[0058] Taking the N-pole conductive connector 1-1 as an example, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com