Online crack detection device for roll for rolling, roll for rolling, and online crack detection method for roll for rolling

一种检测装置、辊轧的技术,应用在辊轧用辊领域,达到避免破坏事故的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

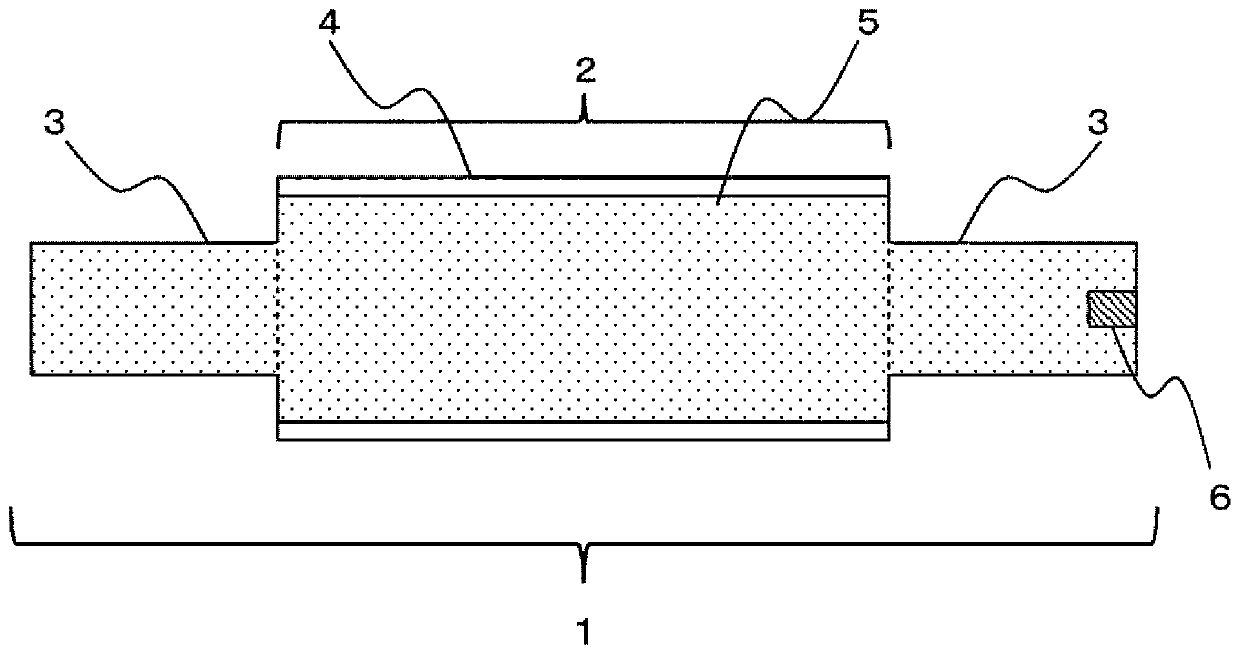

[0048] Below, use Figure 1 to Figure 9 , the online crack detection device for rolling rolls and the rolling rolls according to the first embodiment of the present invention will be described.

[0049] figure 1 It is a drawing which shows the arrangement|positioning of the online crack detection apparatus for rolling rolls and rolling rolls which concerns on the 1st Embodiment of this invention. exist figure 1 Among them, the rolling roll 1 has a trunk portion 2 for rolling a steel plate and a shaft portion 3 extending integrally from the trunk portion for supporting the rolling roll through a bearing (not shown). A composite structure in which the layer 4 and the inner layer 5 are integrated by metal bonding. An in-line crack detection unit 6 is arranged on one shaft portion of the roll for rolling, and the in-line crack detection unit 6 is provided with an AE sensor, a calculation unit, and a discrimination unit.

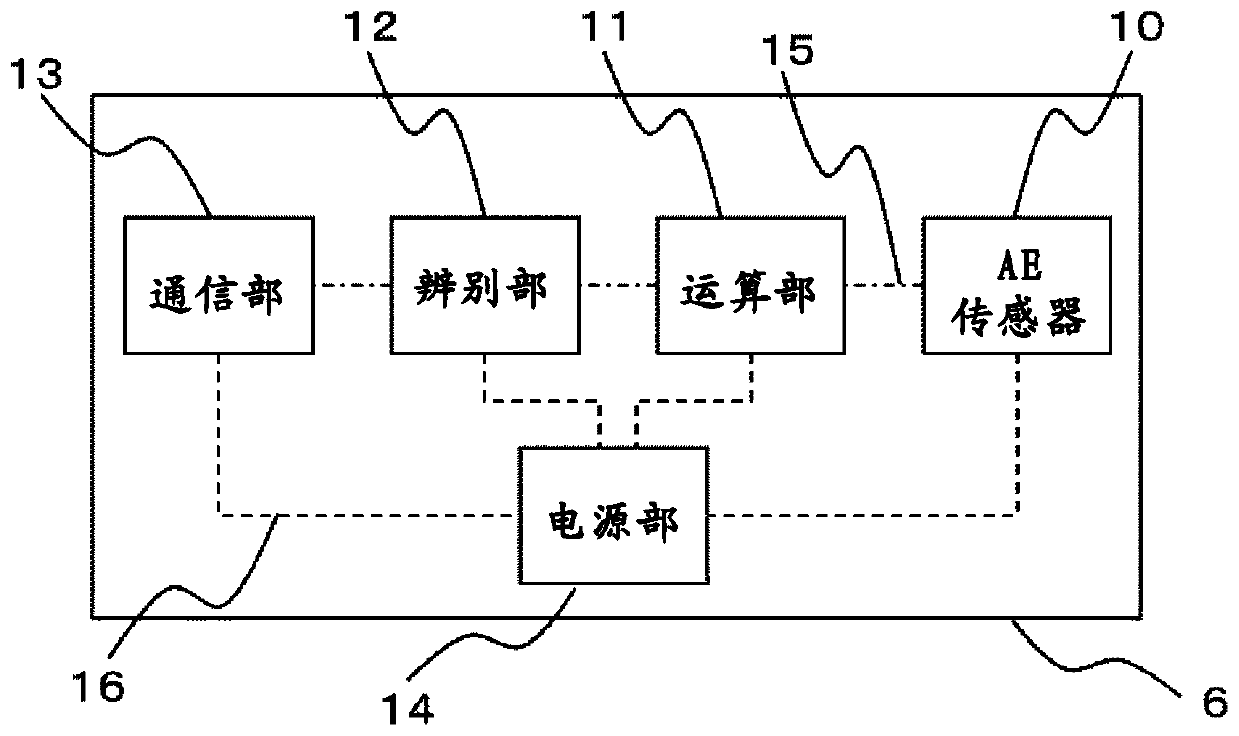

[0050] figure 2 It is a drawing which shows the funct...

no. 2 approach

[0073] Below, use Figure 12 , an online crack detection device for rolling rolls according to a second embodiment of the present invention will be described. Figure 12 A functional block diagram showing a crack detection device built in a rolling roll according to a second embodiment of the present invention. It has an AE sensor 10 that detects the elastic wave generated and progressing on the surface of the trunk part 2, and a calculation part 11 that calculates the characteristic value of the elastic wave detected by the AE sensor 10, and calculates the elastic wave calculated by the calculation part 11. The feature amount data of is transmitted from the communication unit 13 to the server provided with the discrimination unit provided outside the roll. The difference from the first embodiment is that the structure of the crack detection unit 4 disposed on the rolling roll is different. In the first embodiment, the discrimination unit disposed on the rolling roll is dispo...

no. 3 Embodiment approach

[0078] use Figure 9 The first embodiment described is an example in which a lithium-ion secondary battery is used for the power supply unit disposed at the end of the shaft portion of the roll for rolling, but other than that, as long as the mechanism for supplying power to the shaft portion of the roll for rolling can be provided For the rolling device and the vicinity of the rolling device, power may be supplied to the AE sensor, the calculation unit, the discrimination unit, and the communication unit from a power source outside the rolling roll. The specific power supply methods are contact power supply based on collector rings, magnetic field coupling, electric field coupling, radio wave, and laser non-contact power supply. In addition, independent power sources that generate electricity based on the environment can also be combined. Specific examples of ambient power generation include piezoelectric power generation using pressure between rolling rolls and bearings, fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com