Sapling watering device used for garden

A technology for watering devices and saplings, which is applied in the directions of watering devices, gardening, applications, etc., can solve the problems of reducing watering efficiency, increasing the workload of workers, and different growth conditions of small saplings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

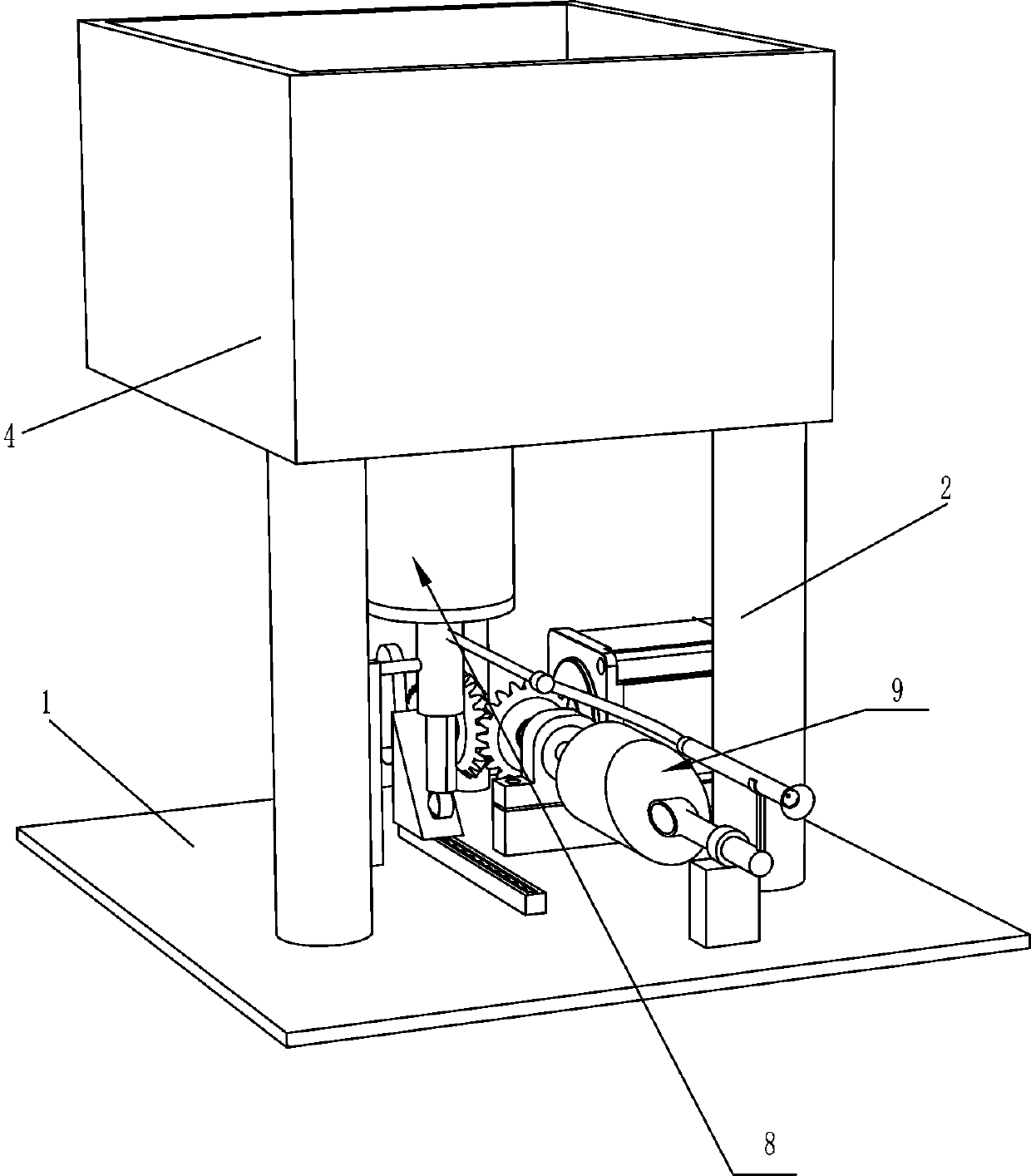

[0022] A kind of small sapling watering device for garden, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a first pillar 2, a second pillar 3, a water tank 4, a rotating rod 5, a baffle plate 6, a driving mechanism 7 and a water intake mechanism 8, and the top of the bottom plate 1 is connected with two first pillars 2, Second pillar 3 is installed on the bottom plate 1 of first pillar 2 front sides, and water tank 4 is fixedly connected between the top of first pillar 2 and second pillar 3, and the bottom of water tank 4 is rotatably equipped with rotating rod 5, and rotating rod 5 is connected with a baffle plate 6, the drive mechanism 7 is installed on the bottom plate 1 on the left side of the second pillar 3, and the water intake mechanism 8 is arranged on the bottom plate 1 on the right side of the drive mechanism 7.

[0023] When the present invention needs to be used, the user adds an appropriate amount of water into the water tank ...

Embodiment 2

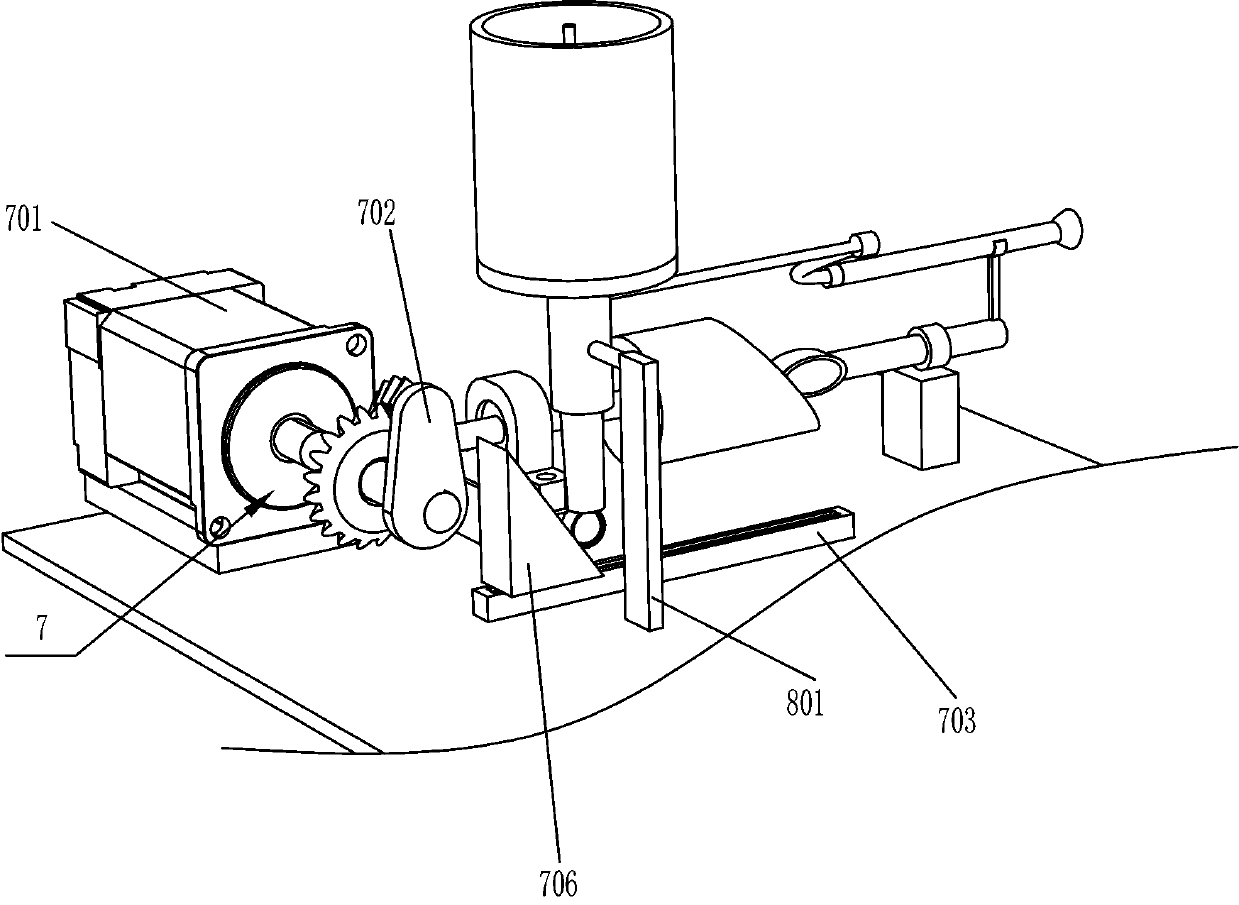

[0025] On the basis of Example 1, as Figure 4 and Figure 5 As shown, the driving mechanism 7 includes a reduction motor 701, a cam 702, a slide rail 703, a slider 704, a first spring 705 and a first wedge block 706, and the reduction motor 701 is installed on the bottom plate 1 on the left side of the second pillar 3 by bolts. On the output shaft of the geared motor 701, a cam 702 is installed, and the slide rail 703 is arranged on the bottom plate 1 on the right side of the geared motor 701 through bolts. The slide rail 703 is slidably provided with a slide block 704, and the slide block 704 and the slide rail 703 A first spring 705 is connected between them, and a first wedge block 706 is fixed on the top of the slider 704 .

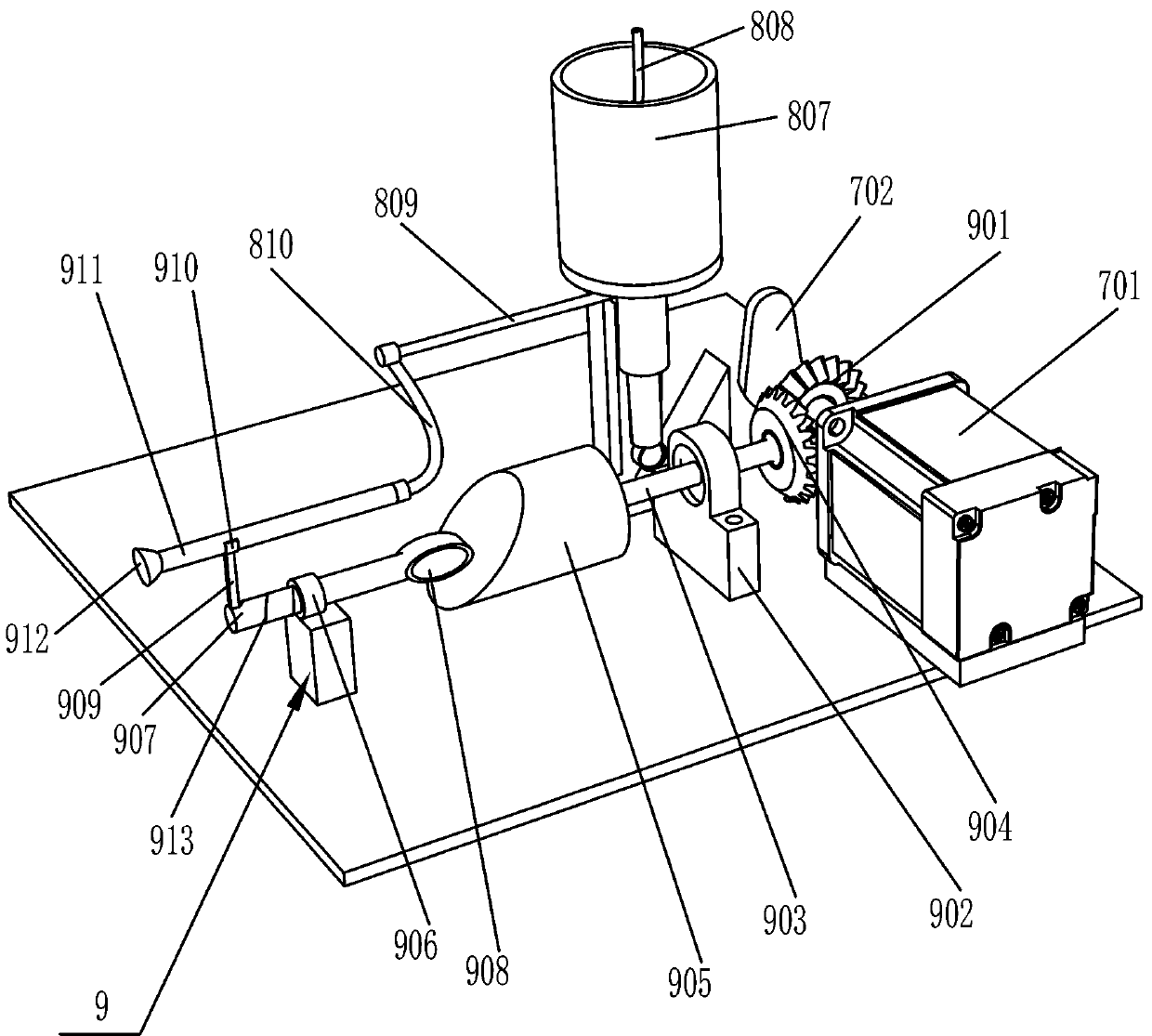

[0026] like Figure 4-7 As shown, the water intake mechanism 8 includes a support 801, a hollow pipe 802, a delivery pipe 803, a moving rod 805, a contact wheel 806, a water intake bucket 807, a connecting rod 808, a water outlet pipe 809 and a fle...

Embodiment 3

[0030] On the basis of Example 2, such as Figure 7 As shown, it also includes a mobile spraying mechanism 9, and the mobile spraying mechanism 9 includes a first bevel gear 901, a bearing seat 902, a rotating shaft 903, a second bevel gear 904, a second wedge block 905, a sliding sleeve 906, a slide bar 907, Contact block 908, pole 909, ferrule 910, water spray pipe 911, nozzle 912 and second spring 913, first bevel gear 901 is installed on the output shaft of reduction motor 701 on the left side of cam 702, and bearing seat 902 is installed on the output shaft of reduction motor 702. On the bottom plate 1 at the right rear of the motor 701, a rotating shaft 903 is installed in the bearing seat 902, and a second bevel gear 904 is installed on one end of the rotating shaft 903, and the second bevel gear 904 meshes with the first bevel gear 901, and the other end of the rotating shaft 903 is equipped with a The second wedge block 905, a sliding sleeve 906 is installed on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com