Pop can cover body packing device

A technology for cans and lids, which is applied in the field of packaging devices for cans and lids, can solve the problems of the complexity of the whole machine, and achieve the effects of high bagging efficiency, ingenious design of the device, and low cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

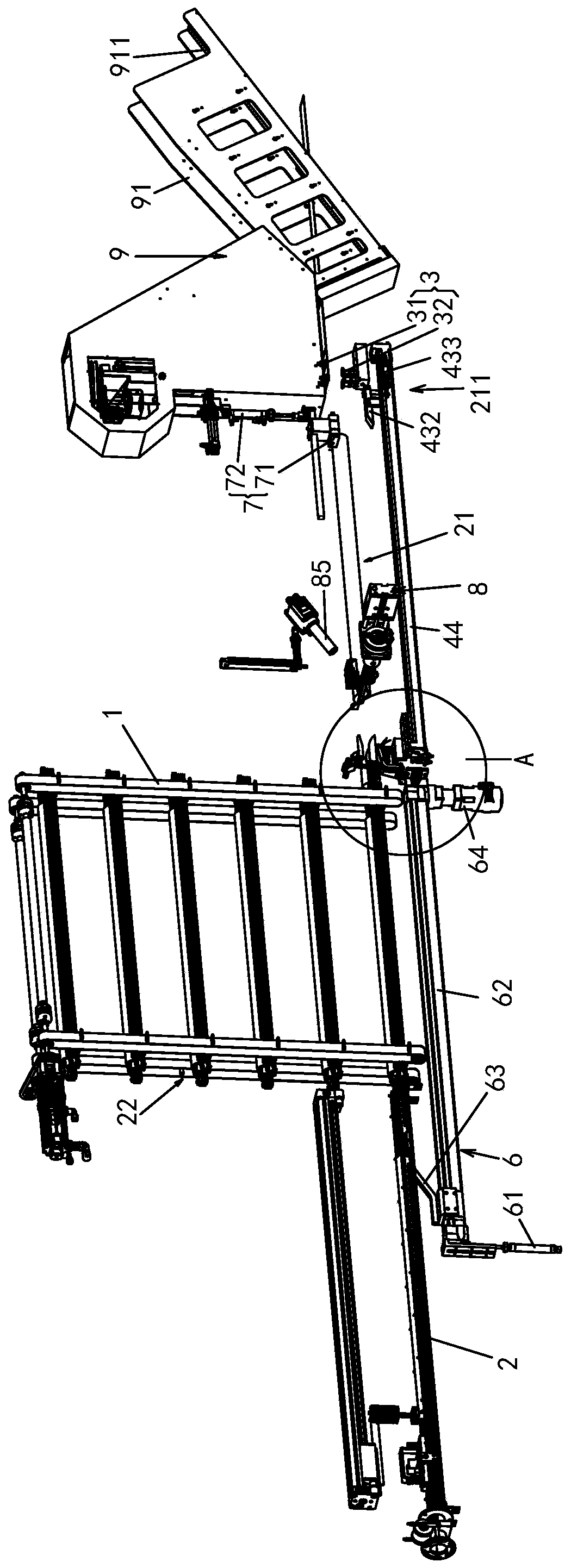

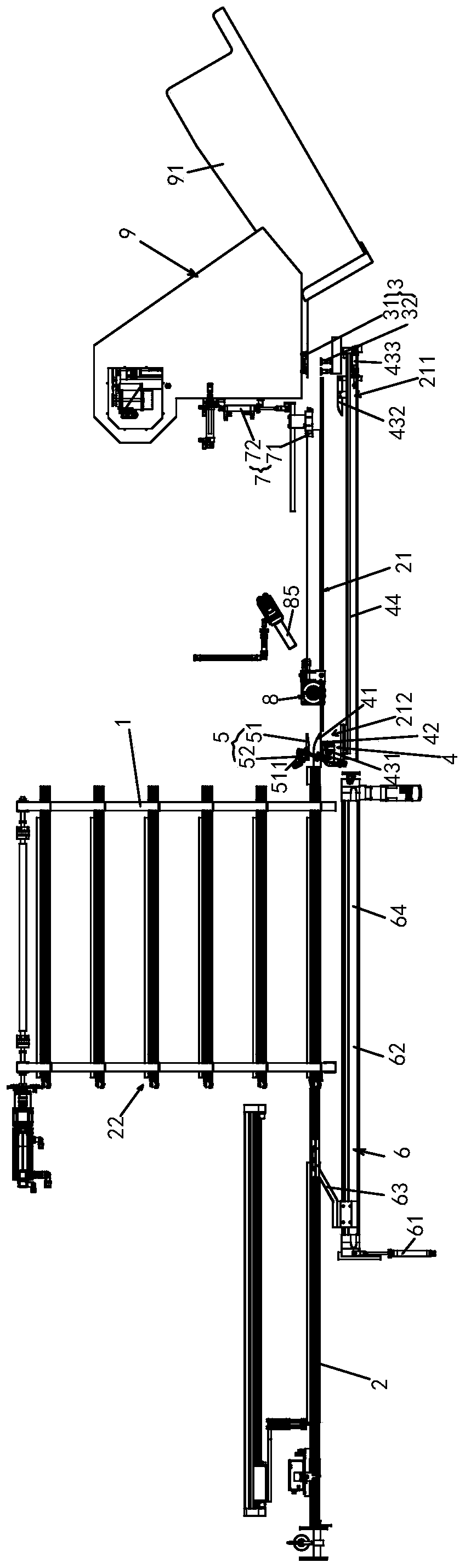

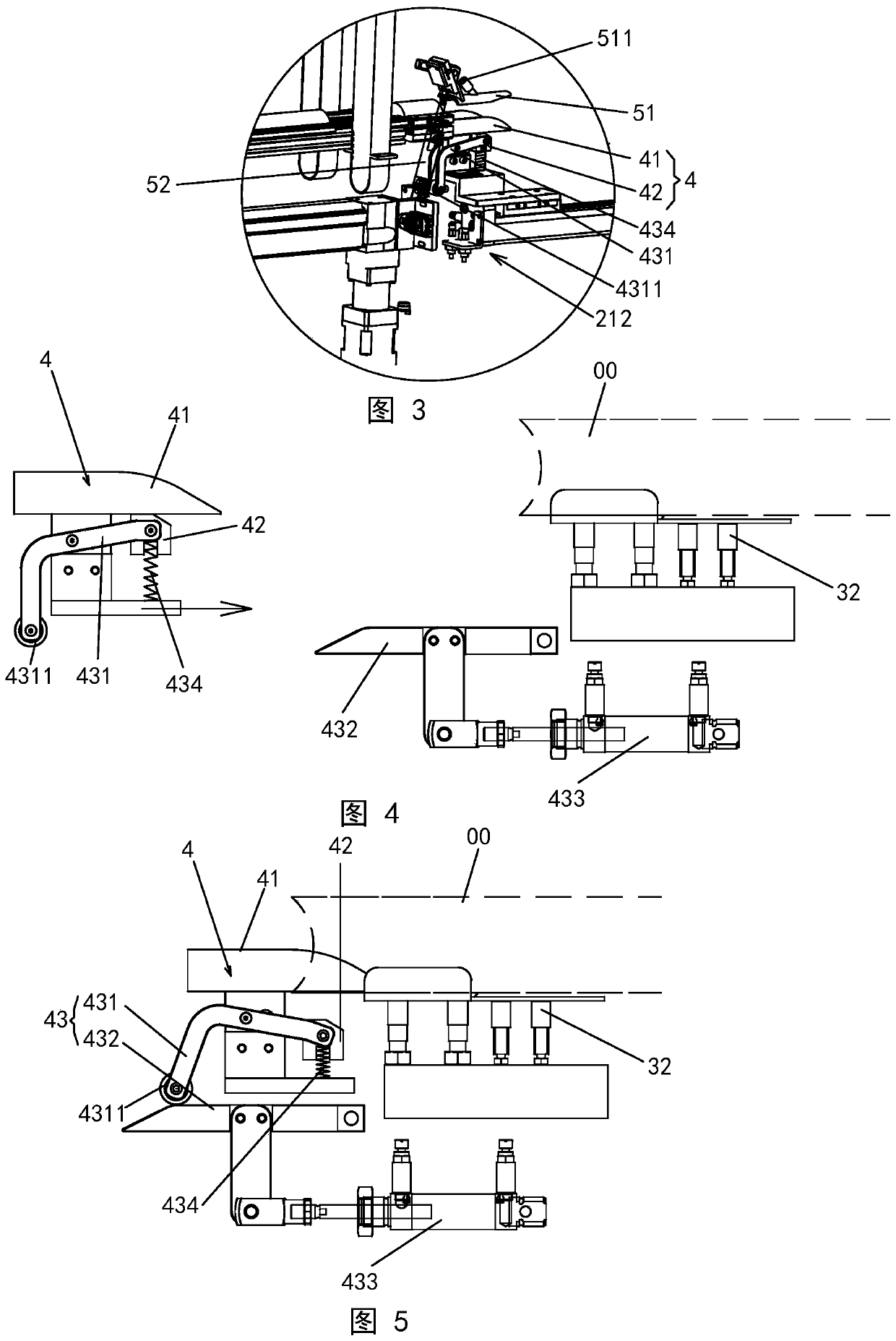

[0047] Example: see Figure 1-19 Shown:

[0048] A packaging device for pop can lids, see figure 1 , figure 2 and image 3 , comprising a frame 1 and a cover track 2 for transporting stacked covers provided on the frame 1, a section on the cover track 2 is used as a cover-push bagging section 21, and the cover-push bagging section 21 is Refers to the position on the device where the core function of pushing the cover 001 into the packaging bag 00 is completed.

[0049] see figure 2 As shown, one end of the push lid bagging section 21 is used as a packaging bag supply position 211 , and the other end thereof is used as a cover body bag entering position 212 .

[0050] see figure 1 , figure 2 and image 3 As shown, the packaging bag supply position 211 is provided with a packaging bag positioning and opening assembly 3, the packaging bag positioning and opening assembly 3 can place the packaging bag on the packaging bag supply position 211 and keep the opening state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com