Novel automatic-adjusting contact-type resistor

An automatic adjustment, contact technology, applied in the direction of the resistance element adjusted by the auxiliary drive device, can solve the problems of excessive current, unsuitable processing, large volume, etc., to achieve stable and reliable performance, clever device design, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

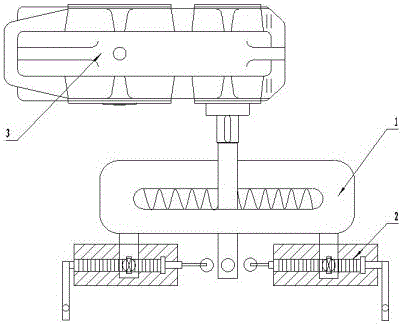

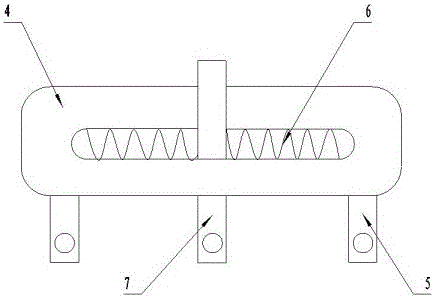

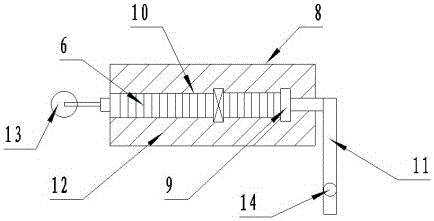

[0022] Such as Figure 1 to Figure 4 As shown, the present invention is a new type of automatic adjustment contact resistor, which is composed of a rheostat 1, a contactor 2 and a regulator 3. There are two contactors 2, which are respectively movably arranged on the rheostat 1 to adjust The varistor 3 is fixedly connected with the varistor 1, and the varistor 1 is composed of a glass glaze 4, a fixed piece pin 5, a resistance wire 6 and an adjustment contact piece 7, and the fixed piece pin 5 is arranged below the glass glaze 4, A contactor 2 is movably connected to the pin 5 of the fixed piece, a resistance wire 6 is arranged in the glass glaze 4, an adjustment contact piece 7 is arranged on the resistance wire 6, and a regulator 3 is fixedly connected to the upper end of the adjustment contact piece 7. The contactor 2 includes a shell 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com