Multifunctional device for testing performance index of steering engine

A multi-functional testing and steering gear technology, applied in the field of shell manufacturing, can solve problems such as large test result errors, difficulty in realizing real-time feedback, inconvenient assembly of counterweights, etc., to achieve ingenious device design, accurate and reliable test results, The effect of high detection efficiency

Active Publication Date: 2020-03-24

武汉宏海兴民科技有限公司

View PDF16 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Whether it is to test the rotation angle and rotation frequency of the steering gear wings, or to test the performance of the steering gear against elastic resistance, most of them currently use the physical principle of levers to measure each wing separately, which will lead to large errors in test results. , the test efficiency is low, and it is difficult to achieve real-time feedback

[0005] As for the performance of testing the anti-constant resistance of the steering gear, most of the previous methods use the hoisting method to measure the performance of each wing against the constant resistance, but this method is inconvenient to assemble the counterweight, and the error of the test results is relatively large. The test efficiency is low, and it is difficult to achieve real-time feedback

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

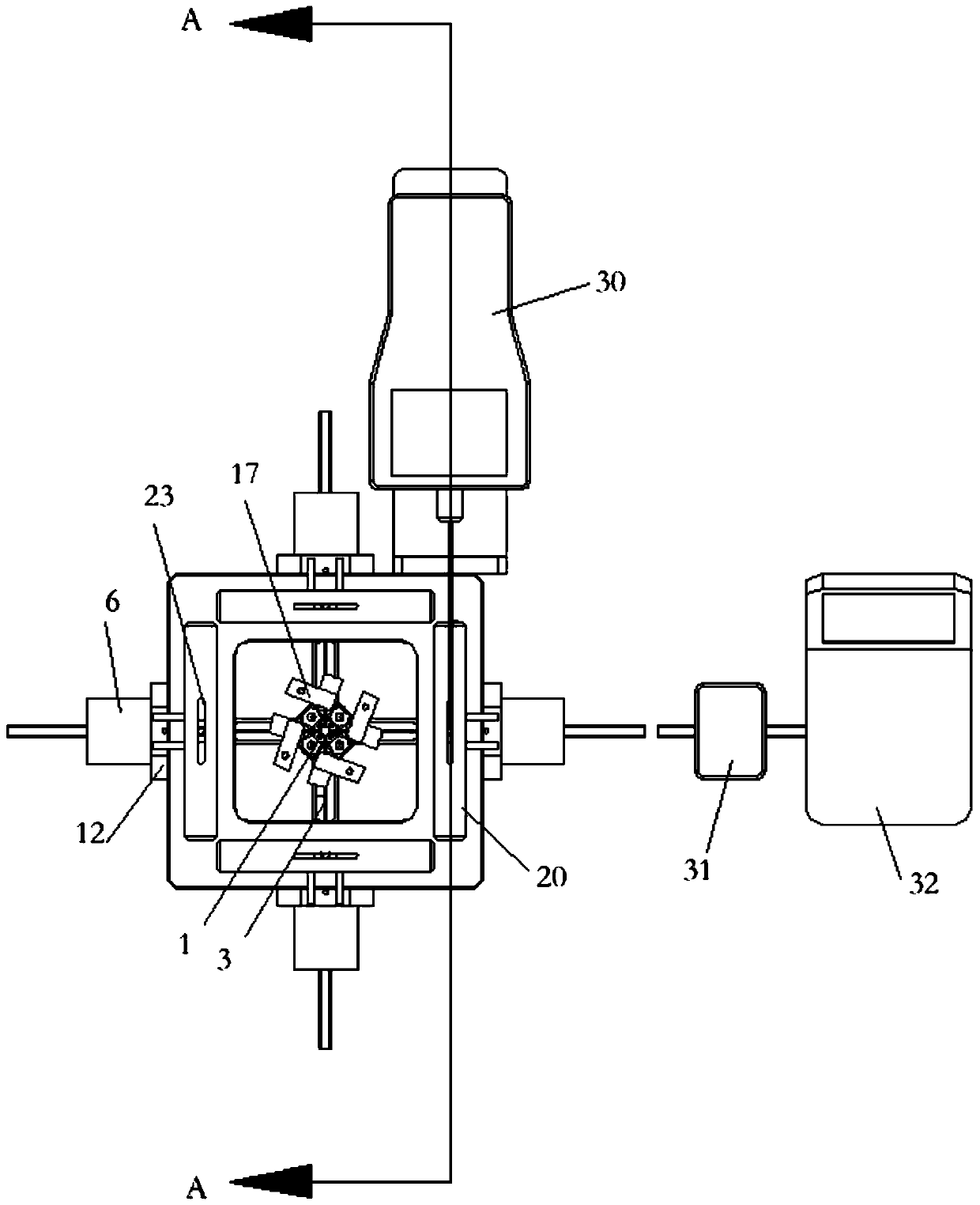

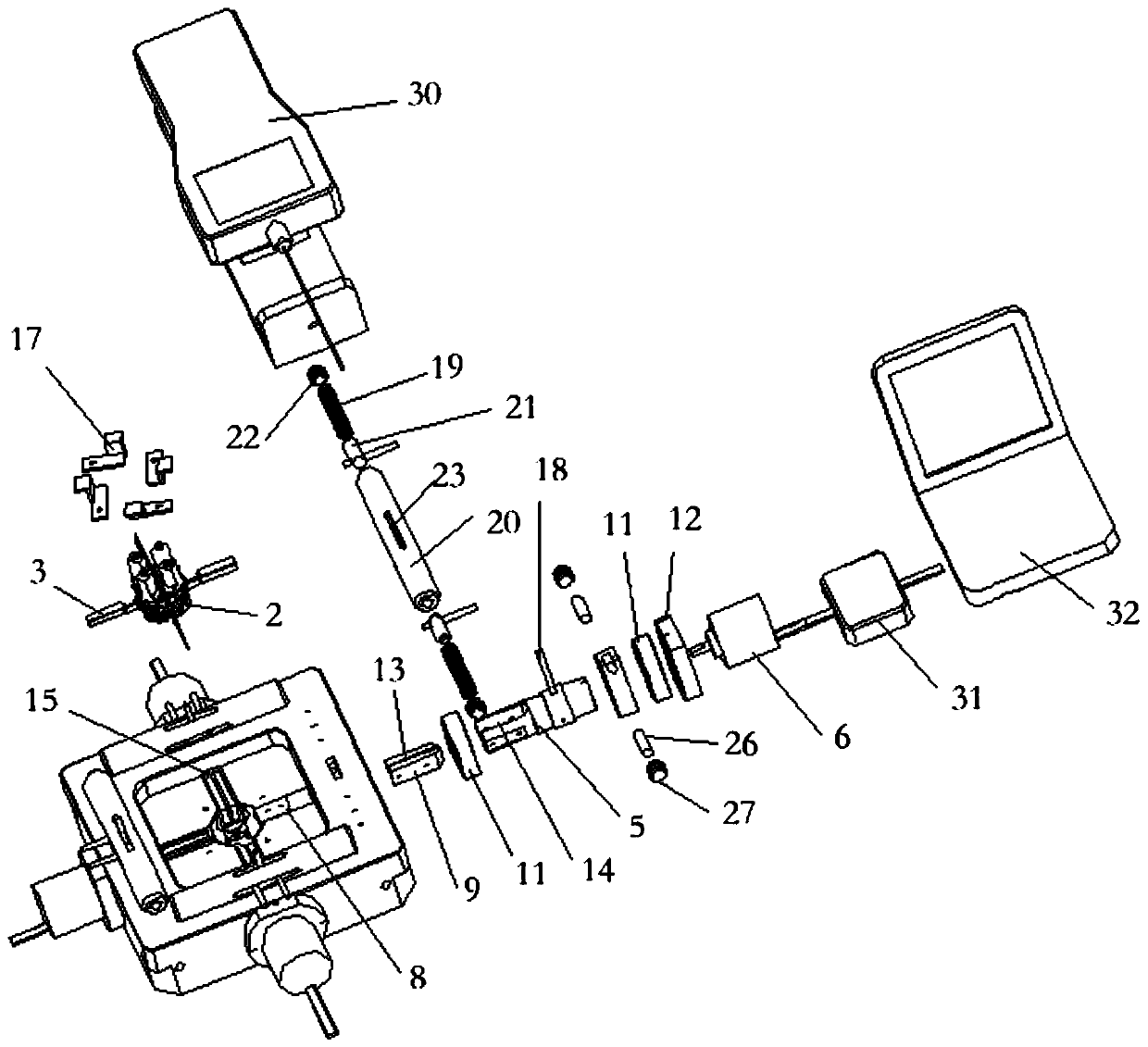

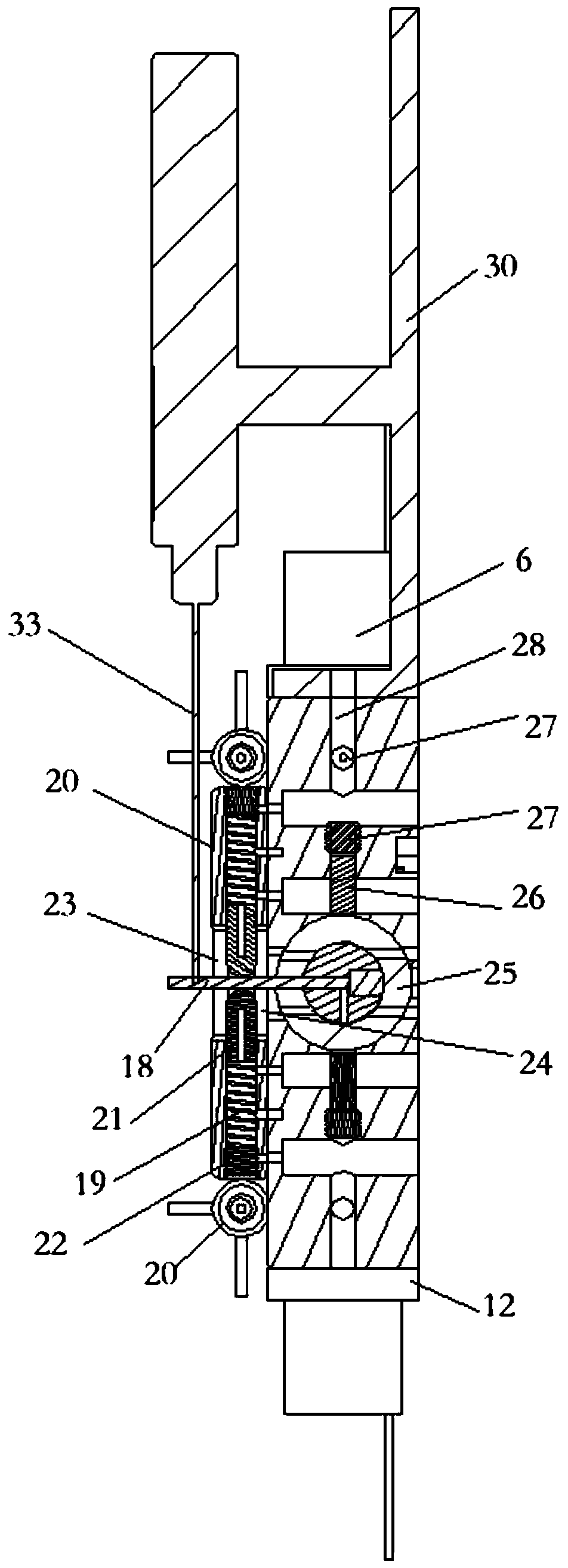

[0033] The structure of the device of the multi-functional test steering gear performance index provided by the present embodiment is as follows: figure 1 , figure 2 and image 3 As shown, it includes a steering gear 1, a blade rotation measuring mechanism, an elastic load mechanism, a constant load mechanism and a dynamometer, and the steering gear 1 includes a steering gear base 2 and four fins 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a multifunctional device for testing performance indexes of a steering engine. The multifunctional device comprises a steering engine, a test board, a fin rotation measurementmechanism, an elastic load mechanism, a constant load mechanism and a dynamometer. The steering engine base is fixed on the test board. The fin rotation measuring mechanism comprises a rotating shaft,a force measuring limiting rod and a rotary encoder. The four rotating shafts are respectively arranged on the test board. The four rotating shafts are uniformly distributed at the periphery of the steering engine base. The four fins are fixedly connected with one end of the rotating shaft respectively. The four rotary encoders are respectively connected with the other ends of the rotary shafts.The lower ends of the four force measuring limiting rods are respectively connected with the four rotating shafts. The four elastic load mechanisms and the four constant force applying mechanisms areinstalled on the test bench, the four elastic load mechanisms apply elastic resistance to the four force measuring limiting rods in the rotating direction of the rotating shafts respectively, and thefour constant force applying mechanisms apply adjustable constant holding force to the four rotating shafts respectively. The device is simple in structure, diversified in function and high in detection efficiency and precision.

Description

technical field [0001] The invention relates to the technical field of cannonball manufacturing, in particular to a multifunctional device for testing the performance index of a steering gear. Background technique [0002] In the precise strike of shells, the steering gear controls the flight attitude and trajectory of the projectile. Therefore, it is necessary to design a high-performance steering gear. The response speed when changing the trajectory when the body is running, the combination of the two will comprehensively reflect the strike performance of the whole body, therefore, it is necessary to verify the rotation angle and rotation frequency of the steering gear blade. [0003] In addition to bearing its own weight during the flight of the projectile, it will also encounter constant speed wind and gust wind, which will produce constant resistance and elastic resistance on the wings. Therefore, it is necessary to verify whether the performance of the steering gear ag...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00G01D5/244

CPCG01D5/244G01M13/00

Inventor 魏星周惠民顾虎涂绪国

Owner 武汉宏海兴民科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com