Cocoon inside-out turning device

A silkworm cocoon and inner layer technology, applied in silk fiber production, textile and papermaking, mechanical processing, etc., can solve the problems of high labor intensity and low manual operation efficiency, and achieve the effect of preventing damage and ingenious device design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

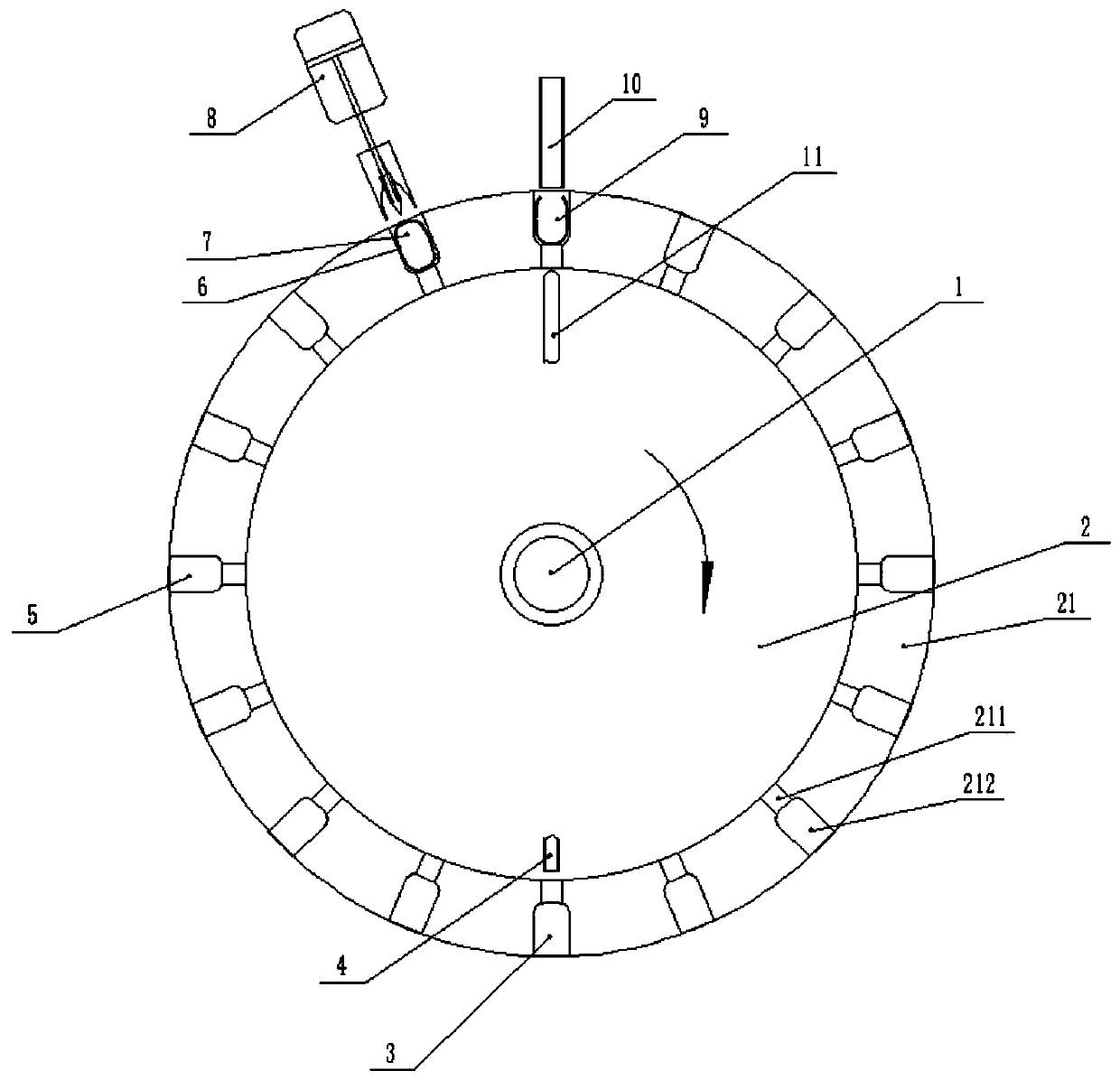

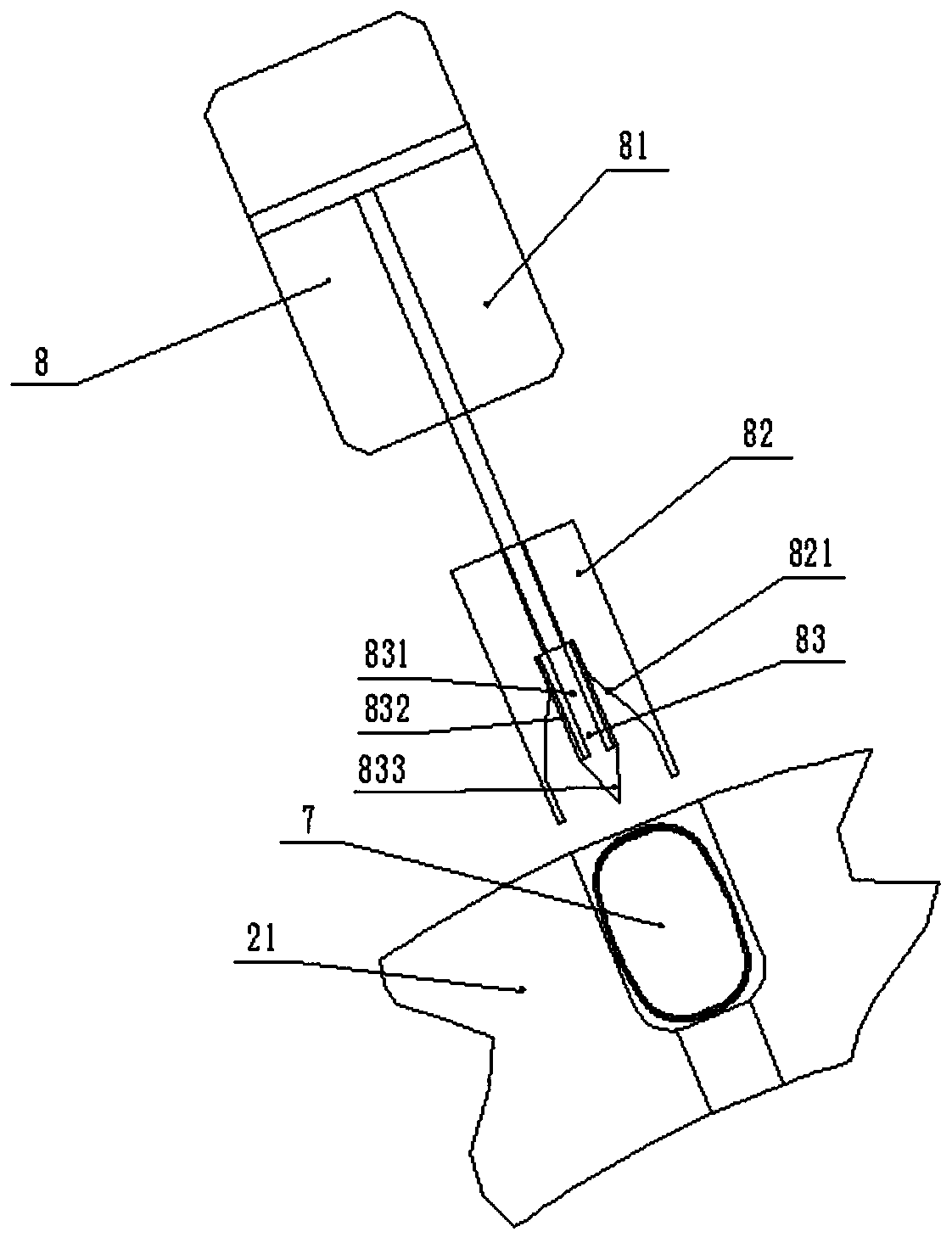

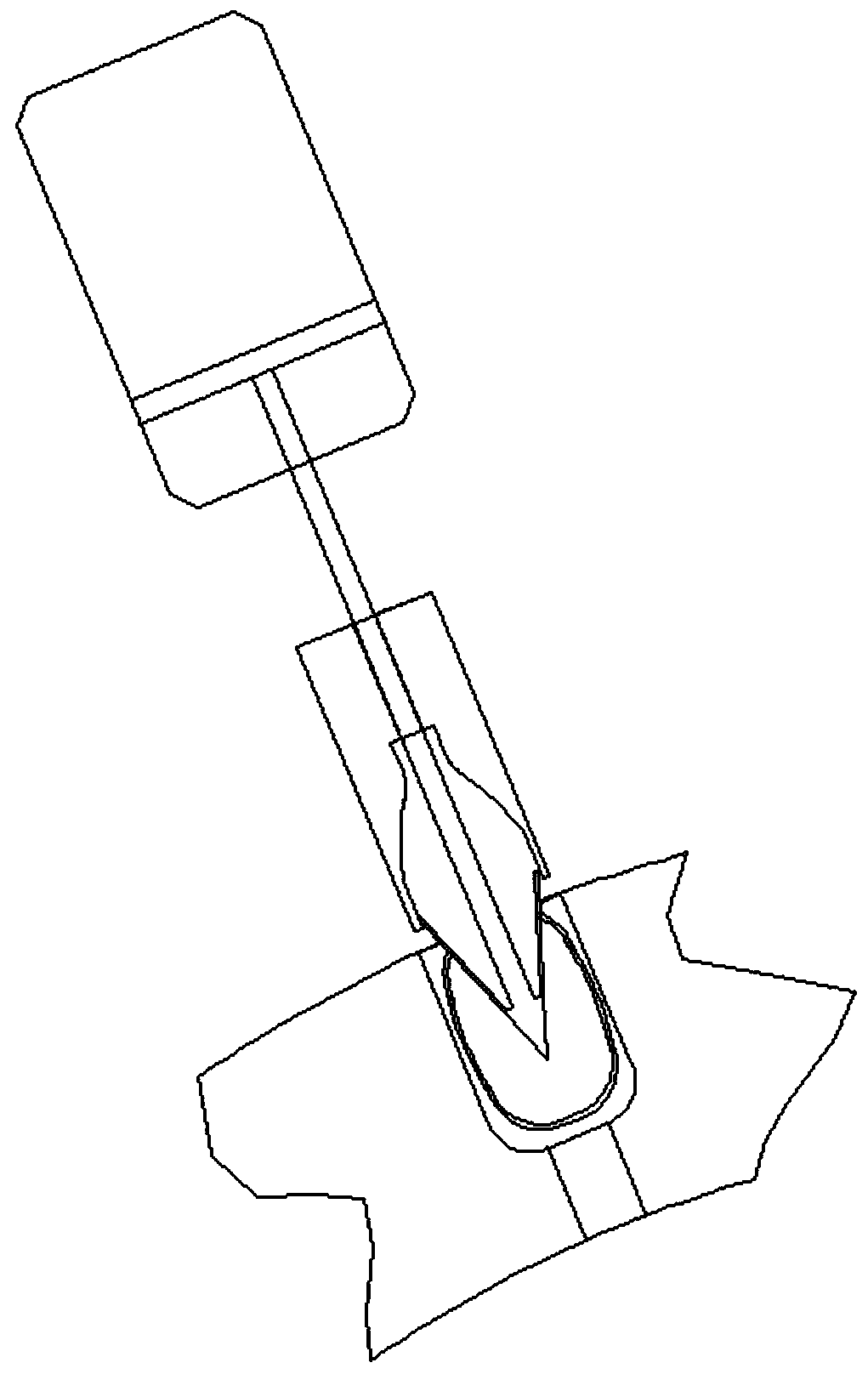

[0026] like figure 1 , Figure 4 As shown, a cocoon inner layer eversion device according to the embodiment of the present invention includes a turntable 2, the surface of the turntable 2 protrudes outward to form a convex edge 21, the cocoon cavity 212 is uniformly processed on the convex edge 21, and the guide channel 211 Processed inside the cocoon cavity 212 and communicated with the cocoon cavity 212; the inner side of the turntable 2 is connected with the cam divider through the rotating shaft 1, and the cam divider drives the turntable 2 to rotate clockwise; The nine o'clock direction is the feeding position 5, the twelve o'clock direction is the turning position 9, and the punching position 7 is between the feeding position 5 and the turning position 9; the punching mechanism 8 is installed on the center of the turntable 2 to punch holes. The extension line of position 7 includes a fixed punching cylinder 81 and a fixed guide block 82. A punching assembly 83 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com