Pump body of vortex type self-priming electric pump and pumping method thereof

A self-priming and vortex technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, pumps, etc., can solve the problems of unsatisfactory suction effect and poor gas discharge effect, and achieve ideal pumping Suction effect, large head effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

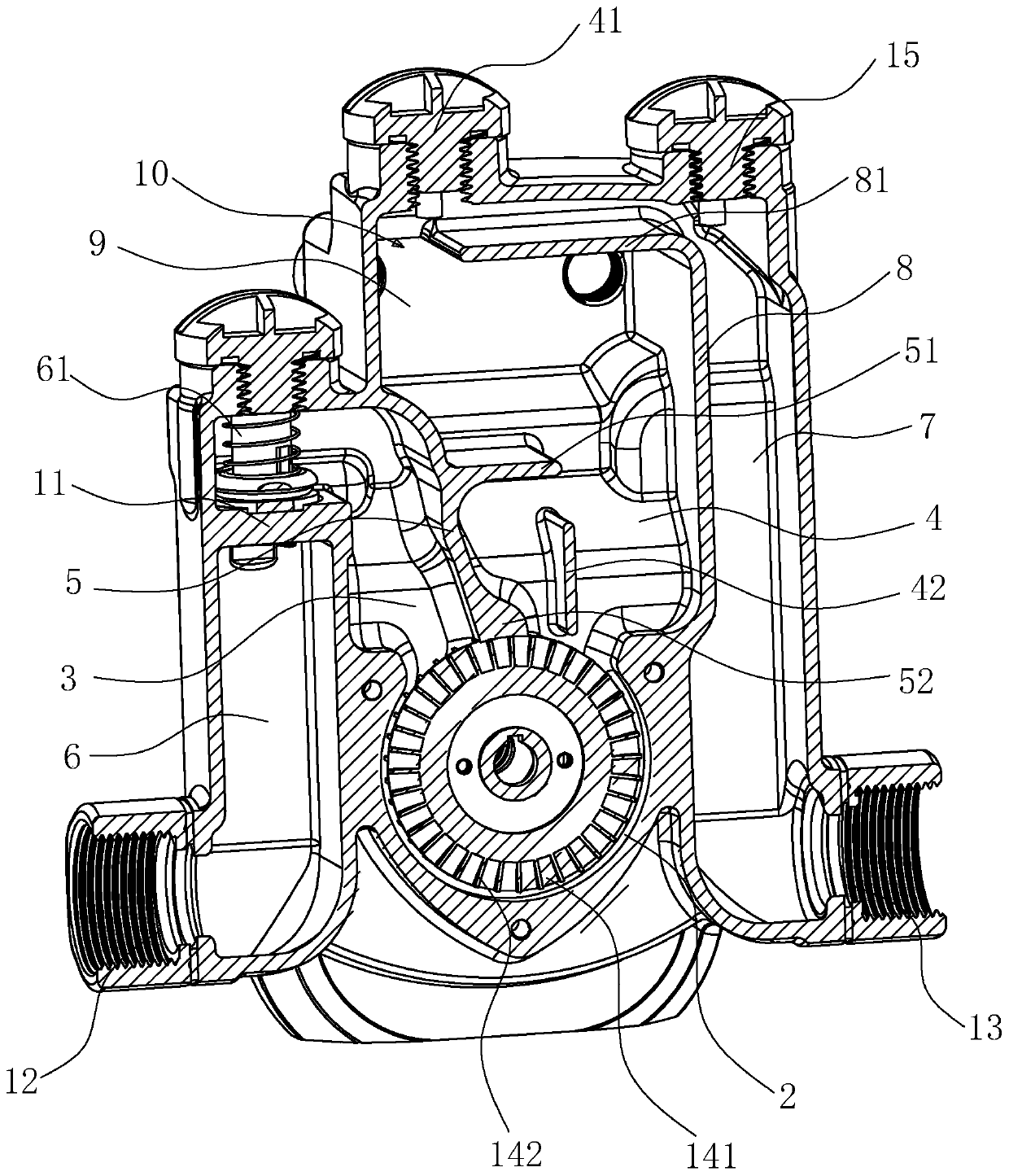

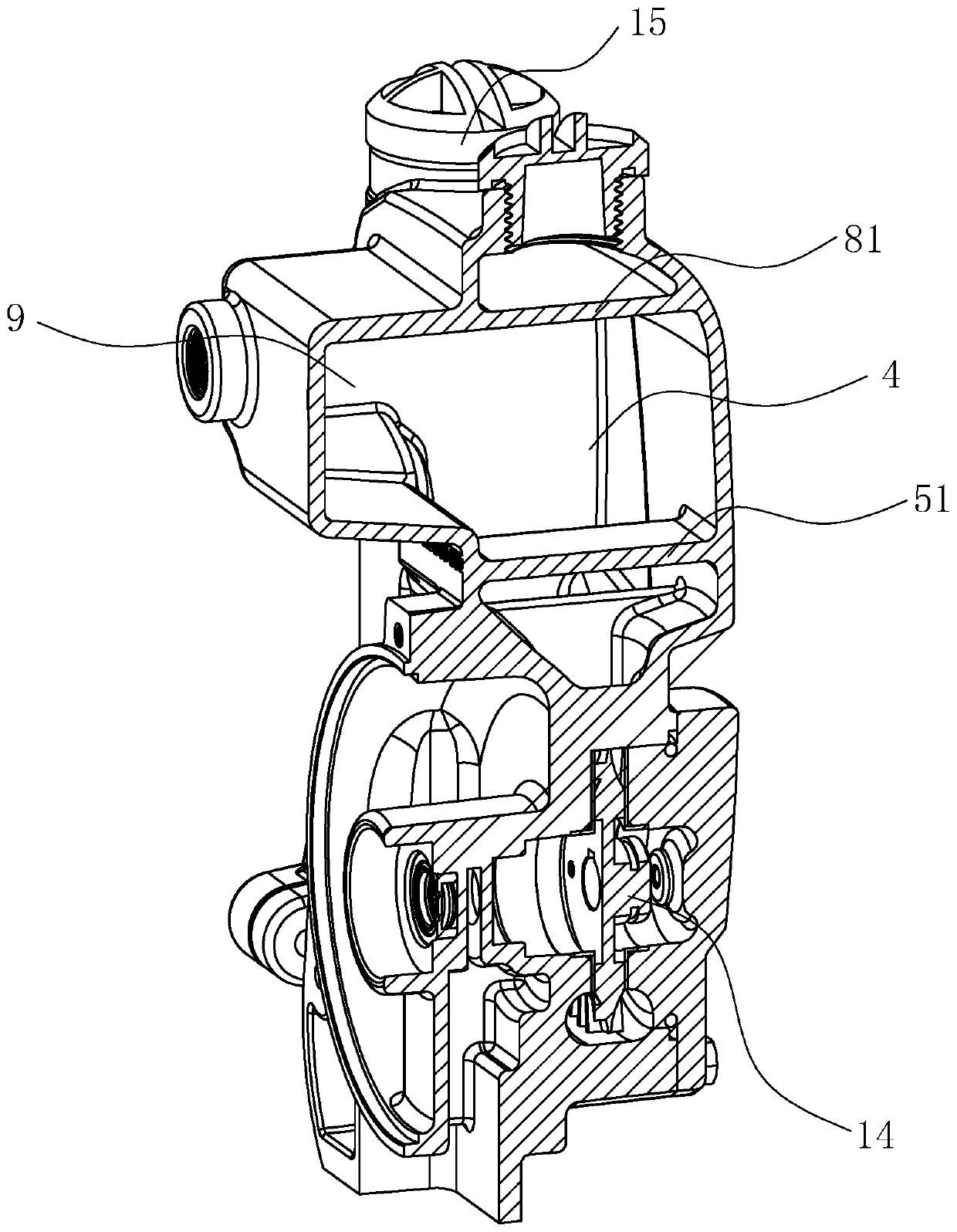

[0034] The pump body of the vortex type self-priming electric pump of the present embodiment, as Figure 2 to Figure 3As shown, it includes a casing 1 and is arranged in the casing 1: a vortex chamber 2 for accommodating the impeller 14, and a water inlet volute 3 and an air-water separation chamber 4 communicated with the vortex chamber 2; the water inlet volute 3 The air-water separation chamber 4 is separated by the compartment wall 5, the water inlet chamber 6 communicates with the water inlet spiral cavity 3, the water outlet chamber 7 communicates with the air-water separation chamber 4, and the water filling port 41 is arranged in the air-water separation chamber 4, in order to pour fluid into the air-water separation chamber 4, a first partition wall 8 is provided between the water outlet chamber 7 and the air-water separation chamber 4, and one end of the first baffle plate 81 is arranged on the first partition wall. On the upper part of the partition wall 8, the othe...

Embodiment 2

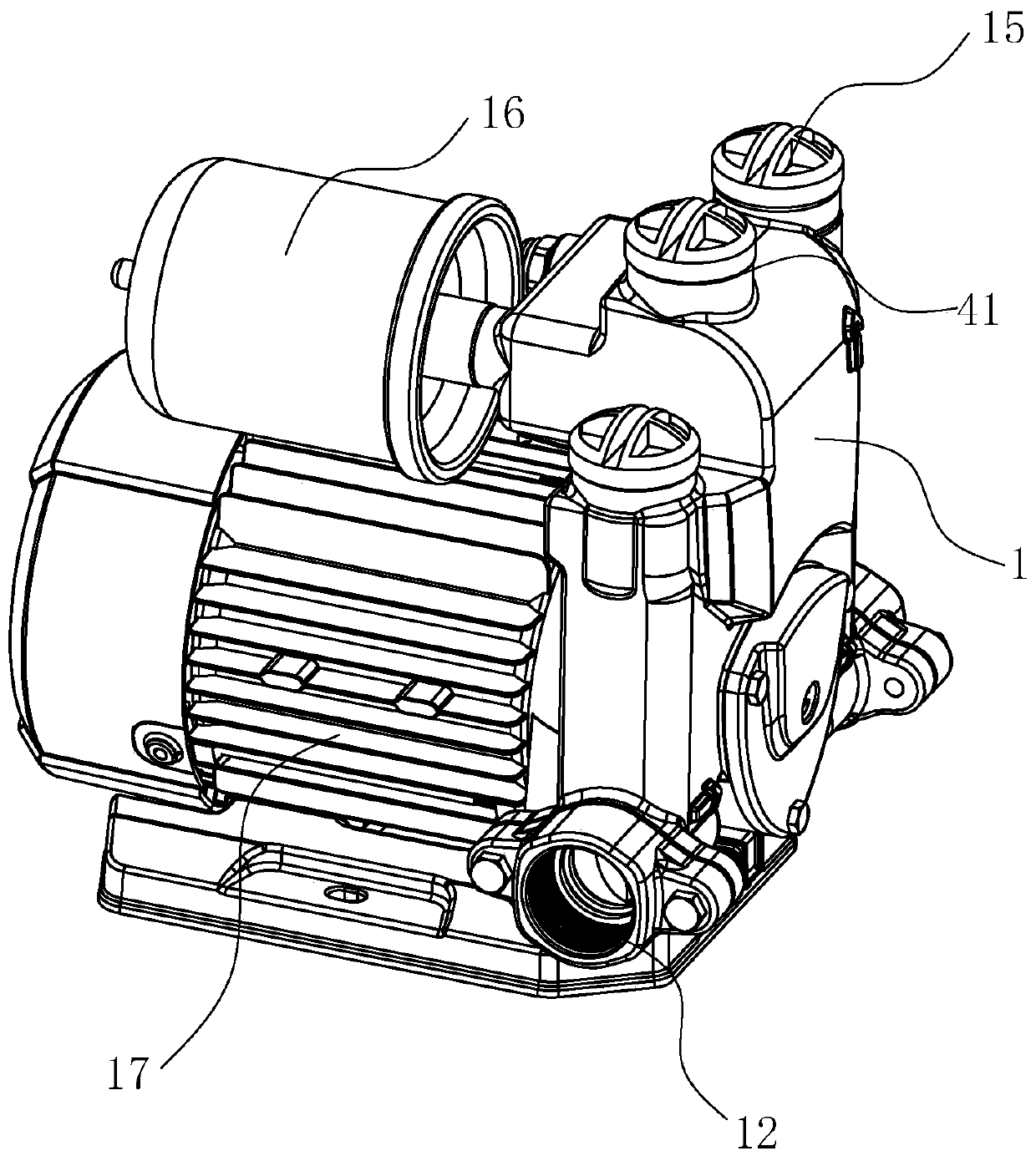

[0045] Such as figure 1 As shown, a vortex self-priming electric pump includes a pressure tank 16, a motor 17 and the pump body of Embodiment 1.

Embodiment 3

[0047] The method of pumping fluid by using the pump body of the vortex self-priming electric pump, the vortex self-priming electric pump used is the vortex self-priming electric pump of embodiment 2, the pump body is the pump body of embodiment 1, and the specific details of the pump body The structure includes an outer shell 1 and the following in the outer shell 1:

[0048] The impeller 14 is provided with a plurality of blades 141, and there is a gap 142 between adjacent blades 141;

[0049] The vortex cavity 2 is used to accommodate the impeller 14;

[0050] The water inlet volute chamber 3 and the air-water separation chamber 4 communicate with the vortex chamber 2;

[0051] The water inlet chamber 6 is connected to the water inlet 12 at one end and connected to the water inlet volute chamber 3 at the other end;

[0052] The water outlet chamber 7 is connected to the first water outlet 13 at one end and the gas-water separation chamber 4 at the other end;

[0053] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap