Knee joint structure

A knee joint and push rod technology, applied in the field of knee joint structure of prosthetic users, can solve the problems of inconvenient adjustment of elastic body strength, easy to exceed critical angle, easy to fall and get injured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is a detailed description based on specific embodiments and drawings.

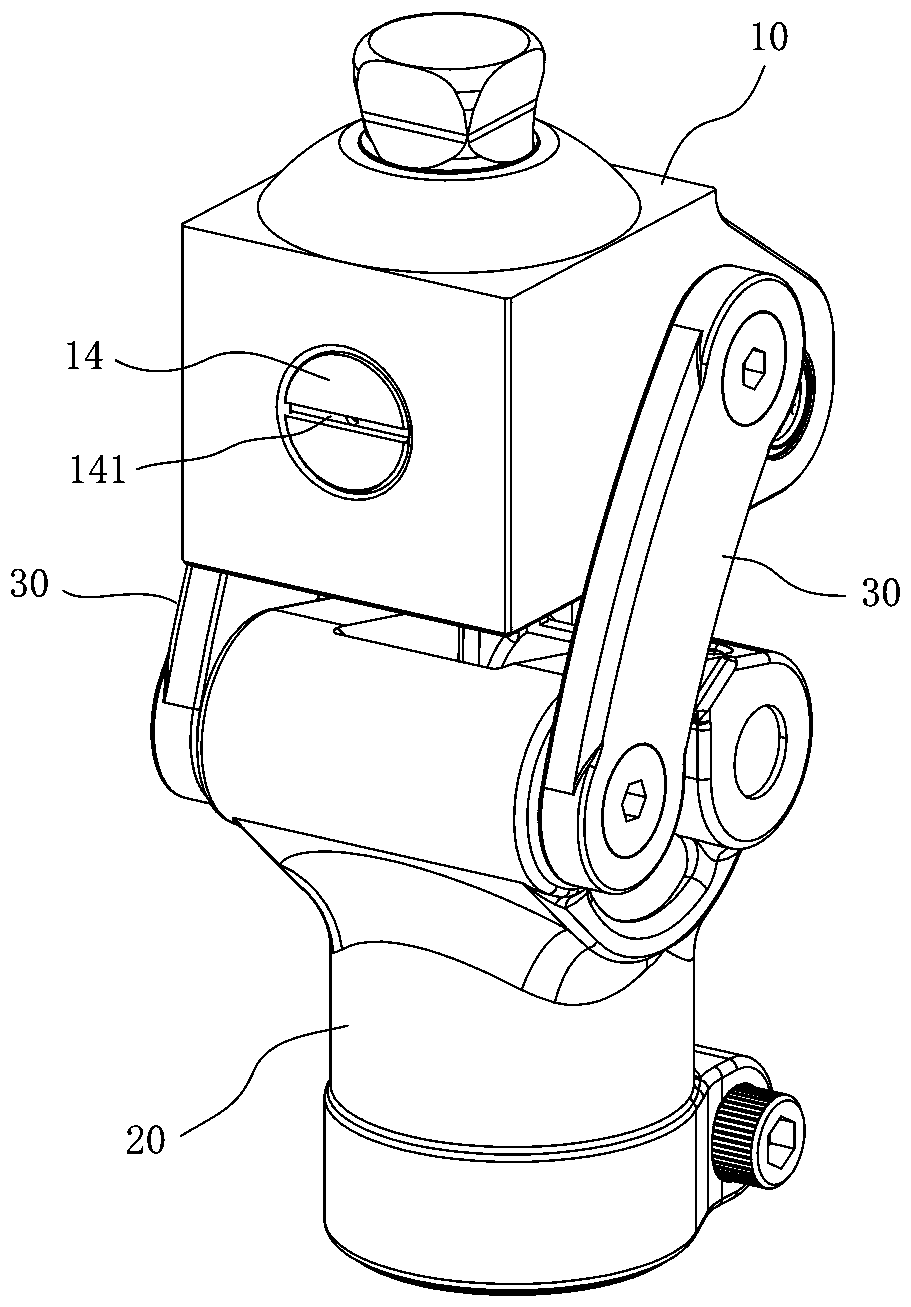

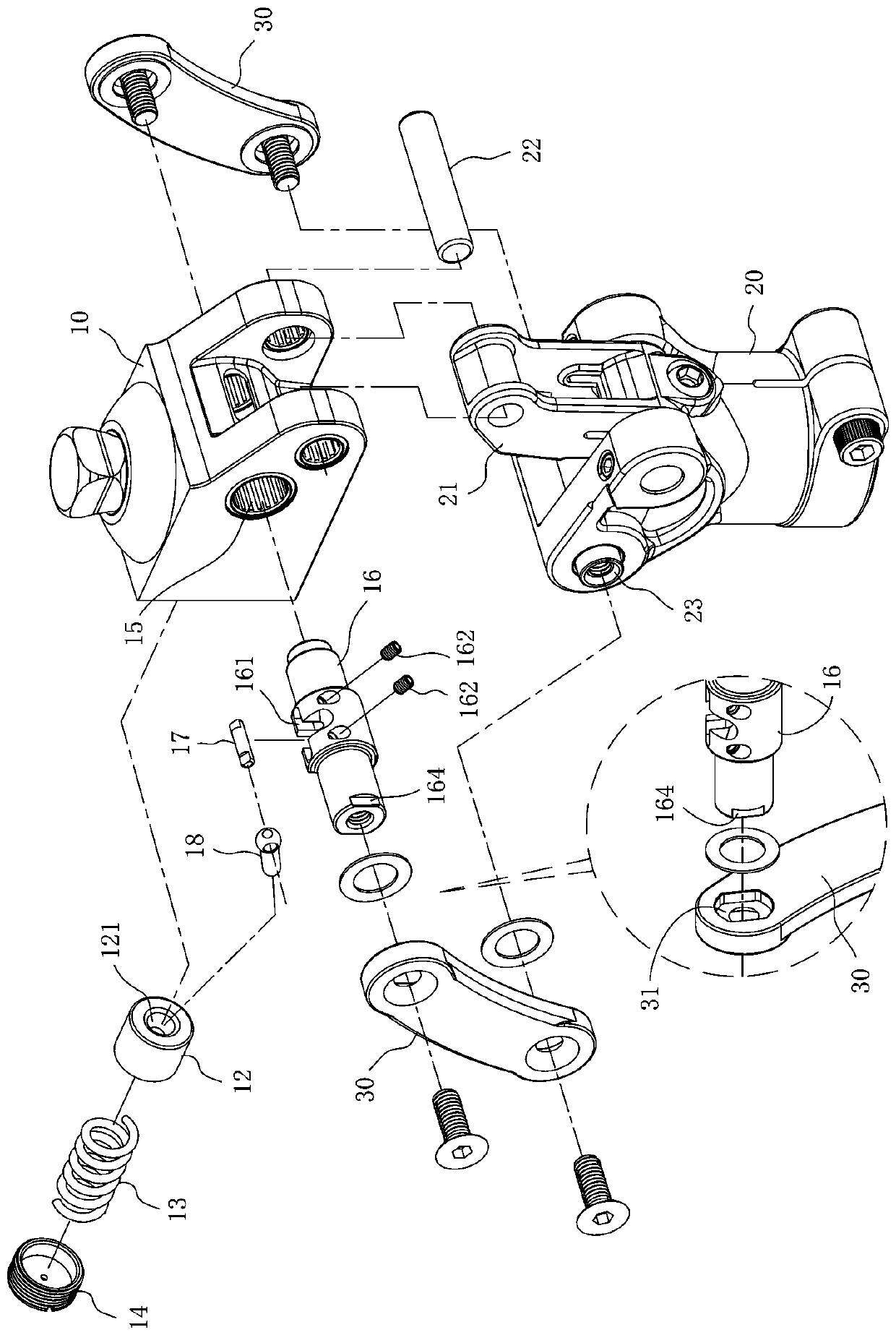

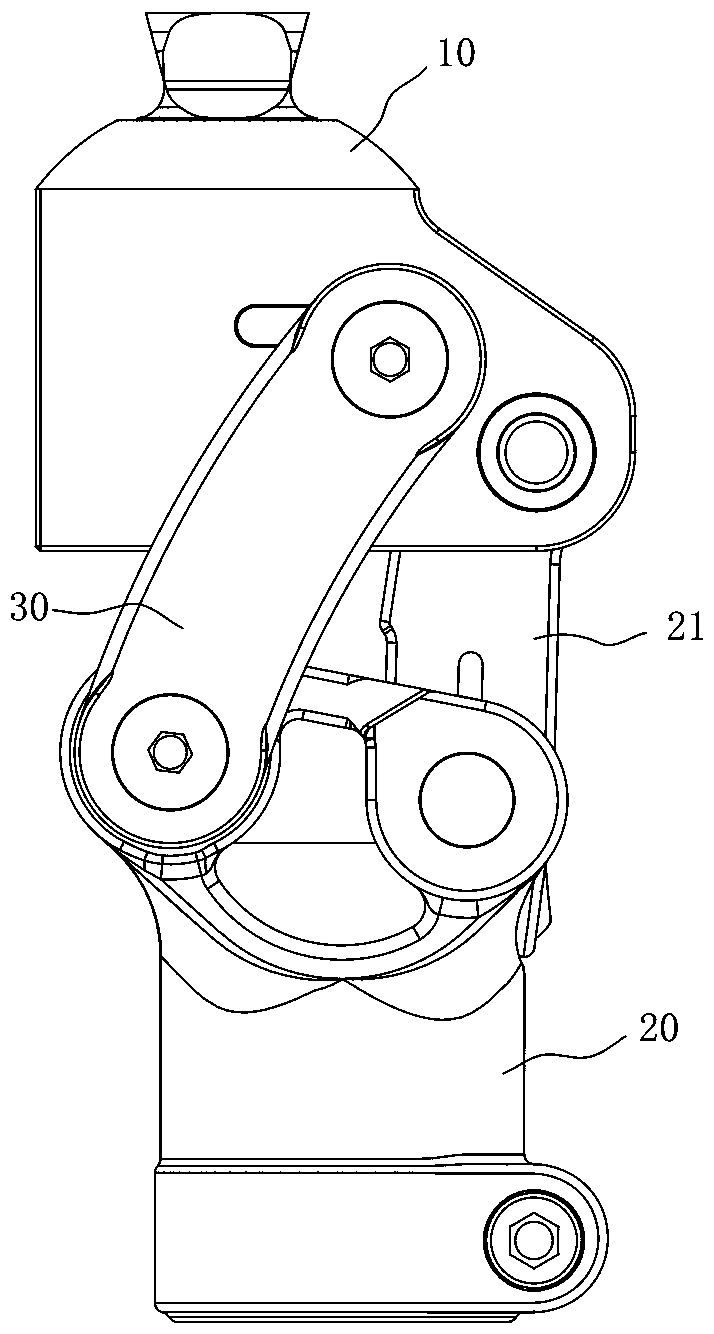

[0046] see Figure 1 to Figure 6 , the present invention comprises a knee joint head 10, a knee joint body 20, and two arc pieces 30. It will be explained in detail below:

[0047] The knee joint head 10 has a reset hole 11, and the reset hole 11 has a piston 12, an elastic body 13, and an adjustment cover 14, and the two ends of the elastic body 13 are respectively against the piston 12, the adjustment cover 14, and Knee joint head 10 has a shaft hole 15, and this shaft hole 15 is provided with a transmission shaft 16, and this transmission shaft 16 has a breach 161, and this breach 161 establishes a push rod shaft 17, and this push rod shaft 17 pivotally connects one and can promote this. Push rod 18 of piston 12 .

[0048] The knee joint body 20 has a connecting rod 21 , one end of the connecting rod 21 is pivotally connected to the knee joint head 10 via a first axis 22 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com