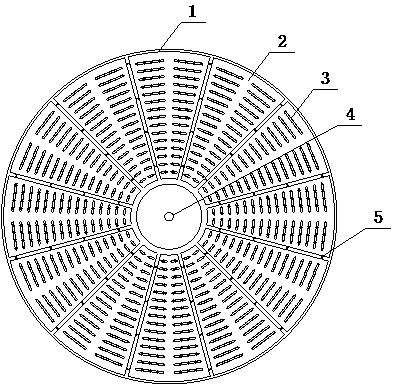

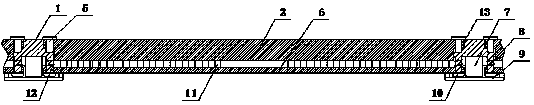

Grate slit structure for ground cement grate plate

A technology of grate plate and grate joint is applied in the field of cement production equipment, which can solve the problems of difficulty in discharging, clogging of grate joints or grate holes, affecting the anti-clogging effect of grate plate, etc., and achieves the effect of improving the anti-clogging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

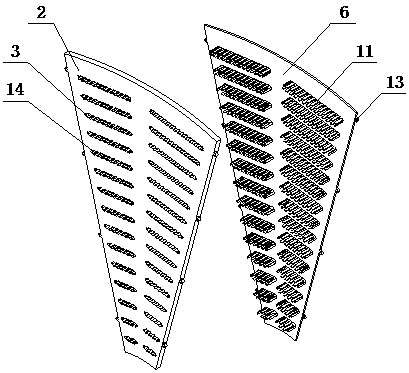

[0023] A kind of grate seam structure used for cement mill discharge grate plate of the present invention is realized in this way: a kind of grate seam structure used for cement mill discharge grate plate of the present invention is composed of main grate plate (2), grate seam (3) , short side arc roller (18), long side straight roller (19), straight chute (20), arc chute (21), straight scraping edge (22), arc scraping edge (23), fillet transition block ( 24) and a connecting shaft (25), the main grate plate (2) has a grate seam (3), the grate seam (3) is a rectangular seam, and the two ends of the grate seam (3) are respectively opened There is an escape groove, the inner wall of the avoidance groove is arched to form an arc scraping edge (23), and the arc scraping edge (23) is provided with locking teeth, and the two short side arcs are respectively placed in the two avoidance grooves, The diameter of the short side arc roller (18) gradually increases from the middle to both...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is: there is an arc-shaped stopper (26) between the long-side straight roller (19) and the relief groove; when in use, it can assist the long-side straight roller (19) to support,

[0027] The diameter of the short-side arc roller (18) is designed to gradually increase from the middle to both ends, which can correspond to the oblong distribution of the auxiliary board (11), so that it can fit the auxiliary board (11) clean up;

[0028] The curved sliding teeth are provided with bristles, and the straight sliding teeth are provided with bristles, which can clean the slot (14) and avoid blockage;

[0029] The rounded corner transition block (24) is equipped with wear-resistant pads to reduce the direct contact friction between the rounded corner transition block (24) and the auxiliary insert plate (11), and avoid the wear of the rounded corner transition block (24);

[0030] The rounded corner transition block (24)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com