Bamboo shoot shredding device for making sour bamboo shoot shreds

A technology for cutting shreds and bamboo shoots, applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inapplicability and inability to clean shredded blades, and achieve the effect of keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

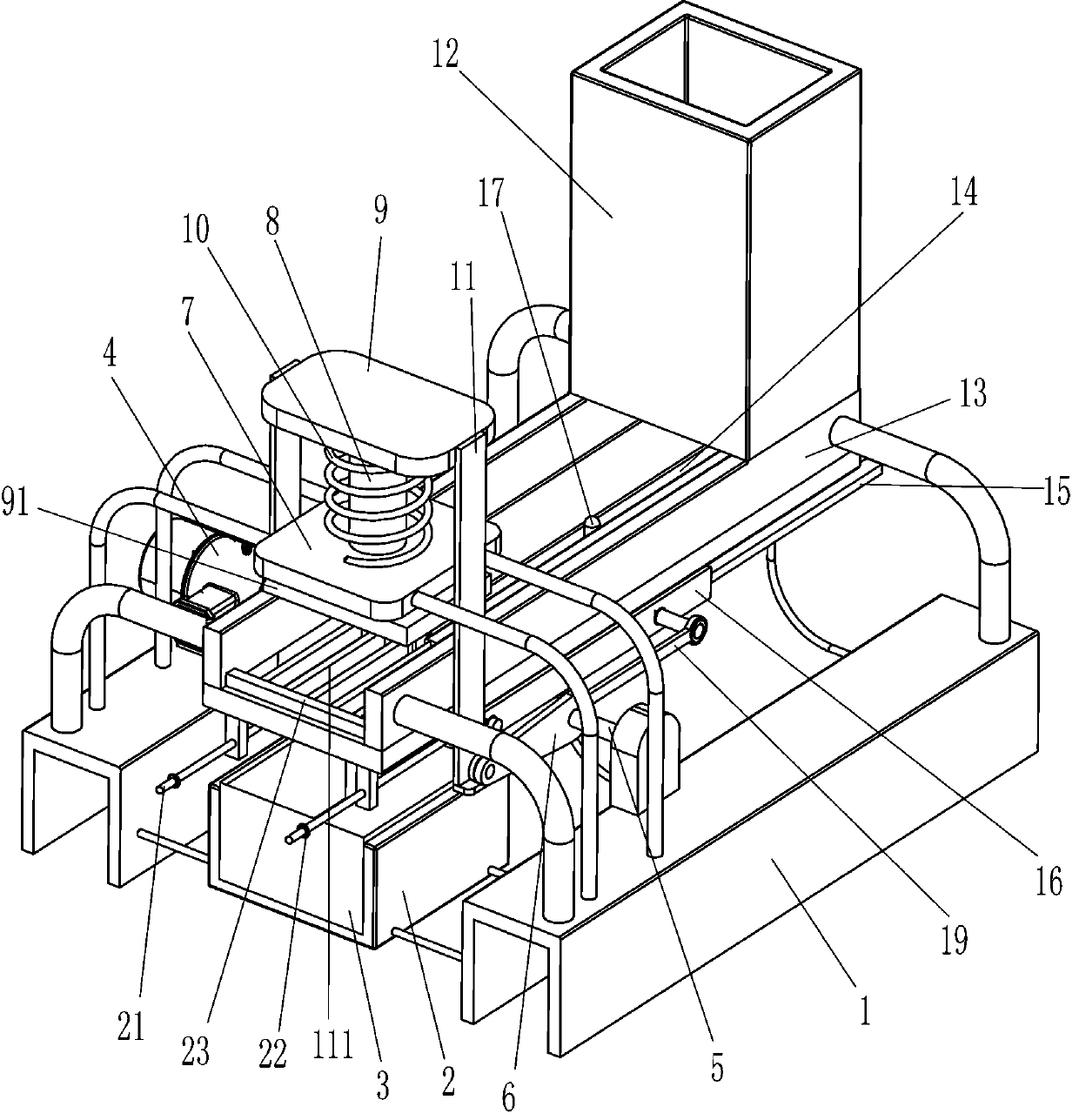

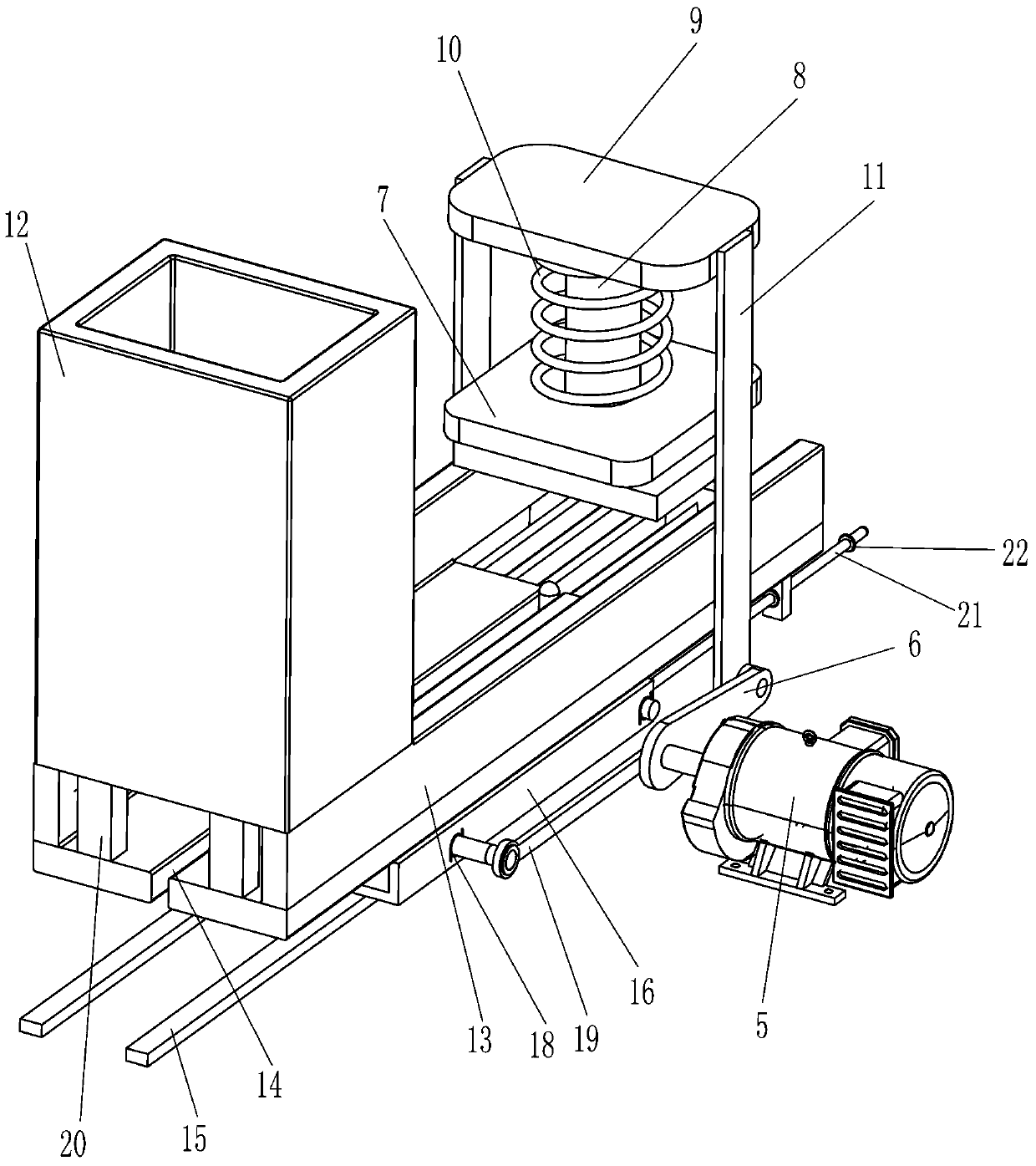

[0018] A kind of bamboo shoot shredding device that sour bamboo shoot shreds is made, such as Figure 1-3 As shown, it includes a base 1, a placement frame 2, a collection frame 3, a shredded assembly and a discharge assembly. The inner front side of the base 1 is fixed with a placement frame 2 by bolts, and the collection frame 3 is placed in the placement frame 2. The base 1 The front portion is provided with a shred assembly that provides power for lifting and shredding by a motor, and the rear portion of the base 1 is provided with a discharge assembly for discharging and shredding bamboo shoots by sliding.

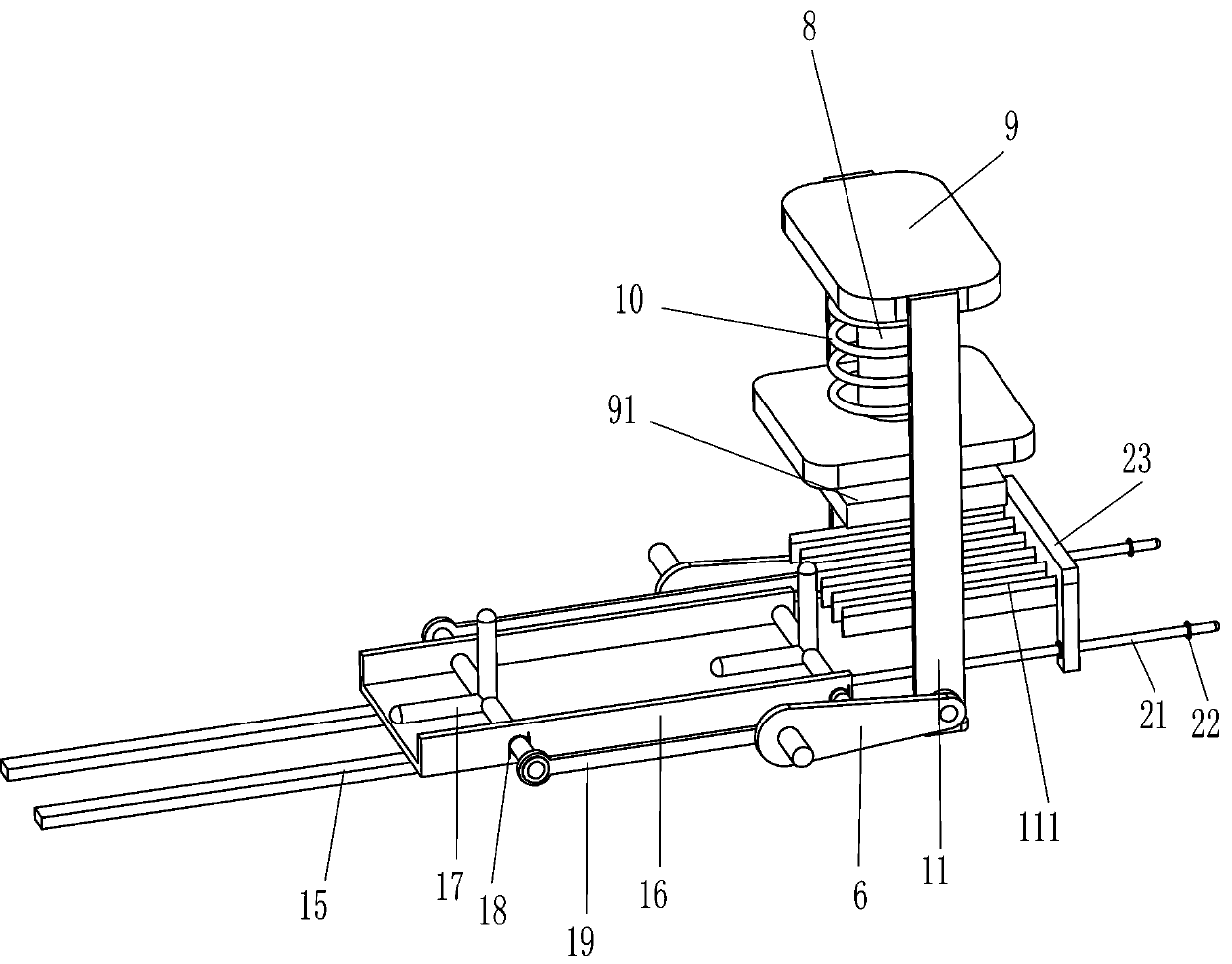

[0019] Such as Figure 1-3 As shown, the shredding assembly includes a reduction motor 4, a rotating shaft 5, a bump 6, a mounting plate 7, a slide bar 8, a connecting plate 9, a pressing plate 91, a compression spring 10, an L-shaped plate 11 and a knife net 111, and the reduction motor 4 is fixed on the front left side of the base 1 through bolts, the rotating shaf...

Embodiment 2

[0025] On the basis of Example 1, such as figure 2 As shown, a limiting plate 20 is also included, and the limiting plate 20 is welded symmetrically to the left and right of the rear side of the guide plate 13 .

[0026] Such as Figure 1-3 Shown, also include slide bar 21, stop block 22 and wiping block 23, slide bar 16 front side is welded with slide bar 21 symmetrically left and right, slide bar 21 fronts are all provided with two stop blocks 22, stop block 22 A wiper block 23 is slidably provided on the sliding bar 21 between them, and the wiper block 23 cooperates with the knife net 111 .

[0027] The working principle of the above-mentioned embodiment: the limiting plate 20 has a limiting function, so as to prevent the bamboo shoots from being pushed away by the push rod 17 .

[0028] When the slide plate 16 moves backward, it drives the slide bar 21 to move backward, and then drives the stop block 22 on the front side to move backward. When the stop block 22 on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com